Onboarding Best Practice Guidelines

Electric engineer

5.1. Development, engineering and procurement - Authorisation

Communication with electricity provider

A. Construction

In this phase, the solar power plant is installed based on installation manuals provided by suppliers to assure the proper storage, handling and installation of mounting systems, PV modules, inverters, transformers, cabling, monitoring system/sensors and other balance of system components. It also ensures the quality of the installation as well as the long-term stability of the PV system.

A proper schedule and preparation of several activities around the construction are important and should preferably be organised according to common project management techniques. This includes clear definition of objectives, activities, and responsibilities (who does what?), time plans and milestones (when?), cost planning, and quality assurance. To achieve this, an effective and efficient communication, documentation and reporting flow between the Asset Owner, the EPC service provider and the subcontractors is necessary. This will help encourage accountability, potential construction defects are promptly identified, high standards upheld, and monitoring the EPC service provider’s performance is easier.

The overall construction activity can be divided into two phases: firstly, the preparatory phase, related to the preliminary activities and secondly, the construction implementation phase, including site preparation, civil, mechanical, and electrical works necessary to complete the plant and bring it to the production phase.

Construction preparatory phase

The construction preparatory phase includes those planning and preparatory activities that ensure the smooth realisation of the PV plant. For this purpose, it is important that the construction project is correctly set up according to project management principles: the Asset Owner and the EPC service provider define project organisation and objectives, arrange main parts of the project in a work-breakdown structure (WBS), deduce a time schedule with clearly defined work packages, including responsibilities/accountabilities (responsibility matrix, for example, a RACI matrix), interdependencies, duration and resources. This time schedule shall be the reference for monitoring the project’s progress from both a physical and cost control perspective and needs to be regularly updated.

Site survey

The site survey aims at checking that there are no physical and geographical constraints or inconsistencies with the assumptions and technical details defined in the Execution design (see Chapter 6 on Engineering). If there are inconsistencies between the execution design and the site survey, the EPC service provider should consider doing another topographical survey with a drone.

The survey is also necessary for checking the actual status of the site and for planning the preliminary activities necessary to prepare the site for the mobilisation of personnel and equipment and the start of the main construction activities.

While the effective mobilisation of the EPC service provider and their subcontractors usually takes place once contracts enter into force (in general when a notice to proceed is issued by the Asset Owner), the execution of certain early works, sometimes also called preliminary works, is a project strategy that is becoming more frequent.

With reference to construction activities set-up, the key topics to be investigated during the site survey are:

· Mapping of the construction site (allotment and boundaries, topography, etc.)

· Definition of the area for temporary facilities and storage/warehouse

· Identification and mapping (geolocalisation) of interferences to be considered during construction, for which drones can be used

· Assessment of critical elements for construction and identification of mitigating actions (technical risks, rests of bombs, hazardous waste, but also archaeological discoveries)

· Detailed survey of transportation facilities and routing and other logistic items

· Execution of the pull-out test, necessary for the final test of the selected foundation design of the mounting structures.

Stakeholder management

The primary tool for understanding the context in which the project is implemented is to identify and understand the stakeholders involved in, or affected by, the project. This allows one to become aware of their expectations and to determine the effective, potential, or perceived impact that the project can have on them identifying methods for involving them.

The identification of the stakeholders and their needs and expectations requires suitable knowledge of the relationships that exist between the different actors that are present and active in a given context. For this purpose, all subjects that could influence or be influenced by the project must be considered.

It is important that the identification of the stakeholders is not limited to local and administrative authorities but should also consider people and organisations that are relevant for local communities, as they represent their interests and identity.

Construction preparation plan

Construction Planning aims at planning all construction activities properly and guaranteeing that resources are available and scheduled consistently with activities. This avoids any unplanned stops.

After definition of the project scope of work, the project management team structures the project by organising the activities in a hierarchical structure, the Work Breakdown Structure (WBS). Only the activities identified with the WBS shall be within the project scope and, therefore, can be planned and controlled. There is only one WBS per project. A well-defined WBS:

· Provides complete definition of the project scope at different levels

· Allocates tasks and responsibilities

· Defines a numbering system, which is used as reference in project plans, reports, and technical documentation

· Provides an input to integrate cost and schedule data

· Ensures the alignment with the contracting execution strategy

· Facilitates the roll up of cost, progress, and schedule performance information for reporting purposes.

All parties (the Asset Owner, the EPC service provider and other service providers) involved in the project should comply with the WBS and related coding system. Clear and effective communication between the Asset Owner, the EPC service provider and other service providers (and in general, all third parties involved in the project), and constant monitoring of the construction work progress according to the WBS, are key to ensuring full alignment on scope of work, objectives, deliverables, and timing.

WBS’s lowest hierarchical items are the work packages (WP). By defining each WP in detail and considering dependencies, the project plan is created. Each WP should contain at least the following information:

· Name

· Unique number/code

· Version and status information

· Description of content and results to be obtained

· Prerequisites and dependencies (deliverables required etc.)

· Projected duration

· Resource requirements (people, material, tools, vehicles, etc.)

· Person responsible for the WP

A detailed scheduling of the activities, including milestones, is essential to completing the work in a timely manner. Proper scheduling of the works is mandatory for correctly managing and controlling the progress of the project. If the work plan has not been prepared appropriately, mistakes and delays cannot be identified, and corrections cannot be implemented. Furthermore, the project plan needs to be updated regularly.

Project managers derive subordinate plans and documents from the central project plan. For example, the EPC service provider and other service providers will have planning, scheduling, reporting, and documentation obligations, according to the stipulated contract. With reference to the WBS, contractors should be responsible for the lower-level activities schedules and plans. A typical document for this phase is the mobilisation plan, which includes:

· Construction site organisation chart: the subcontractors (civil and electro-mechanical) need to provide the construction site organisation chart which indicates all the expected positions, the staff residence times and the expected hours.

· List of site vehicles and equipment: subcontractors must provide the list of vehicles and equipment they intend to use for different kinds of work, accompanied by certificates of suitability and maintenance and/or testing sheets.

Work plan and mobilisation plan guarantee in-time arrival and accommodation of construction site personnel and assembly materials. They also ensure that the different elements of the construction phase are properly coordinated.

Based on the defined project schedule (baseline), the associated physical progress curve should be determined, to establish a reference plan for the percentage of physical completion of the project at each date. This is key for proper project monitoring.

To calculate the project’s physical progress, one must define specific calculation rules to apply to each elementary activity type, as well as determine the weighting criteria.

The construction plan should also define processes and procedures relating to the interface of the construction team with the rest of the project staff, in particular with the engineering, EHS and quality management teams. It should be assured, for example, that all the project changes proposed by the EPC service provider and other service providers are checked and approved by engineering department (change management). Furthermore, the construction activities should be verified in accordance with the quality control plan and HSSE procedures (quality management). Other control activities concern cost/budget, HSSE compliance, documentation, etc.

Check and finalisation of working permits

Country-specific legislation and regulations around HSSE and construction activities are continuously evolving. It is critical to be sure that all works, administrative permits, and authorisations have been obtained to avoid breach of any legal provision. Such a breach could result in severe consequences, both in terms of personal and administrative sanctions and in downtime and delay in the execution of the activities.

A useful tool to ensure full compliance is the prescription and authorisation checklist which should identify all the relevant legislation and regulations applicable to the specific project and location. It also lists all requisites necessary to start the construction activities (authorisations, particular training requirements for certain works, such as works at height, land lease agreements, etc).

Activation of external suppliers (services and materials)

Once all preliminary activities have been assessed and completed, the construction activities are ready to start. All subcontractors and suppliers must be activated according to the specific clauses of the relevant contracts and based on the scheduled activities. The scope of this phase is to ensure that all resources are present at the site in a timely manner to avoid any downtime and delay.

Construction implementation phase

Construction site activities must be supervised by the EPC service provider’s Construction Manager. They should coordinate with the Asset Owner’s Construction Manager and the Construction Supervisor on the monitoring and control of subcontractors. Throughout construction, drone construction monitoring flights should be carried out periodically to monitor, record and report on construction progress and quality. The data from these scans can also provide valuable support to H&S, stock management, and adherence to local planning and environmental regulations.

Construction site organisation

Construction site organisation refers to the preparation of the site for the start of civil, mechanical, and electrical works.

The effective mobilisation of the EPC service provider and related subcontractors usually takes place approximately 60 days from the signature of the contract. However, preliminary site preparation and executive engineering may begin immediately after signing.

In the mobilisation phase, contractors will begin to mobilise direct and indirect labour, equipment and means so that all planned activities can start as scheduled.

Site preparation main activities are:

· Opening of the construction site

· Archaeological survey may be requested by local authorities depending on the historical interest of the site

· Removal of vegetation removal and the superficial part of soil where foreseen (this kind of activity should be minimal in accordance with a positive biodiversity strategy)

· Staking and beating of the poles of the structures

· Visual mitigation works planned.

Civil works

Civil works refers to excavation for the construction of cable ducts, including foundation, MV overhead line supports, preparation of the areas where inverters and DC boxes will be installed, distribution station, road construction, and any earthworks in general.

They must be planned and implemented to minimise the interference and the overlap with the electro-mechanical activities described below, which are often difficult to manage from a safety point of view.

Biodiversity issues need to be considered to minimise the impact of civil works. Where this is not possible, restoration or compensation measures should be taken, but it is always better to reduce destruction during works. Raising the awareness of personnel and clear guidelines can help to achieve this.

Electro-mechanical works

Mechanical activities mainly consist of:

· Withdrawal of materials from the Contractor warehouse

· Assembly of metal structures

· Installation of PV equipment / panels

· Package / cabin assembly

· Tests and inspections

Electrical activities mainly consist of:

· Laying ground network (equipotential bonding)

· Laying DC (LV) solar cabling and related components for connecting PV module strings to inverters using tools certified/qualified by the manufacturer for PV cable-connectors assembly. At present DC cabling configurations can vary a lot but nevertheless, laying DC cabling is a key element of the electrical works

· Laying MV cables from transformer stations to the distribution station

· Laying LV auxiliary cables

· Cabin and field connections

· Tests and inspections

Ancillary works

Ancillary works are activities that are not directly connected with the assembly of the “electric generation plant”. They refer in general to security (fencing, CCTV, lighting, …), vegetation care, internal roads, signposting, and so on and so forth.

These works, even if not prioritised, must not be underestimated because they could delay the handover of the entire plant.

Grid connection

Utility scale PV plants need to be connected to the network, usually managed by the Transmission System Operator (TSO). Connection complexity depends on the distance between the plant and the substation, its conditions and the technical solution identified for the connections. These works are the final stage of the construction activities and normally require the involvement of the TSO, which should be scheduled well in advance.

Checks and functional tests

Once the plant is completely built and connected to the grid, one must test that it works properly. It is important that tests are carried out according to a detailed procedure agreed between the EPC service provider and the Asset Owner.

To this end, the EPC service provider must send the Asset Owner a detailed plan of execution of all the work necessary to reach Start-up (Start-up Plan), before the start of the Mechanical Completion and Pre-Commissioning activities of the plant.

The plan should include the following minimum requirements:

· Definition of a start-up team

· Definition of the project functional units and related sub-units

· Definition of the plant sections that can be put into production in sequence

· Definition of the schedule and procedures for carrying out the preparatory tests for the start-up for each functional unit and plant section

· Description of how to perform the Mechanical Completion and Pre-Commissioning tests on the functional units

· Description of the execution of the Commissioning tests on the functional units and on the entire system

Mechanical completion

When the plant is completely built and connected to the grid, after a visual inspection, the Asset Owner issues the Mechanical Completion Certificate (MCC).

The aim of the visual inspection is to verify:

· That all components and materials are present and in accordance with the project documentation

· The compliance of the completed project with the project documentation, the Technical Specification, and the current legislation

· The electro-mechanical completion of the plant

· That all components are free of visible damages that could compromise the safety of the components and personnel

· That the components have been installed correctly

· The correct identification and labelling of all components such as inverters, DC boxes, cables, support structure rows, switches, communication devices, monitoring elements, etc.

· The correct execution of the connections

· An aerial survey to validate the asset against its design layout

Training of Asset Owner and O&M service provider

As soon as the plant is ready for operation, after MCC has been issued, the EPC service provider should arrange for a specific training for the Asset Owner and the O&M service provider’s personnel (that could be a third-party or the O&M division of the EPC service provider). This training can transfer the knowledge and philosophy with which the plant has been designed and constructed.

Training is important as it allow the O&M service provider’s staff to familiarise themselves with the plant and its operations. Poor training standards can result in lower performance of the plant, due to delays in detecting system malfunction signals, resulting in longer downtime as faults are resolved. This is also an opportunity for the O&M service provider to give feedback to the construction (and engineering) team, especially if both belong to the same company.

The Asset Owner’s personnel should also receive training. This will help avoid misunderstandings between the Owner and O&M service provider and make their collaboration more efficient and effective.

A comprehensive and detailed as-built documentation (Annex E), manuals and procedures (Annex C “Documentation set accompanying the solar PV plant” of the O&M Best Practice Guidelines) should be part of the training activities. For more information on the handover to a specialised O&M service provider, please refer to Chapter 10 on Handover to O&M.

B. System Commissioning

System commissioning is one of the most important stages of the EPC service provider’s work as it closes the construction period and prepares the PV plant for commercial operation. This crucial step of the project includes performance and reliability tests. These make sure that the PV plant is built according to the international standards and industry best practices, and that it complies with the requirements as agreed with the Owner, grid specifications and guaranteed performance levels. Tests are undertaken for all individual components from checking that components function to more detailed measurements and verifications of the overall system. Successful commissioning and timely achievement of the Commercial Operation Date (COD) is linked to the release of a milestone payment as defined in the contract as well as the release of the performance bond. It is, therefore, very important that the contract clearly describes the requirements, criteria, documentation, and reporting required to complete the EPC service provider’s scope of work and handover to the Asset Owner and the O&M service provider’s team.

Pre-commissioning

Mechanical completion happens the final construction stage meaning that all principal components that are part of the PV plant have been erected or installed. At this point, the EPC service provider will usually conduct a detailed inspection of the works, possibly accompanied by the Owner or any third-party representative (such as a technical advisor). This option should be clearly stated in the EPC contract clause referring to commissioning (if the Owner intends to apply it). Activities carried out under pre-commissioning should be detailed and agreed in advance with the Asset Owner in a specific document.

The pre-commissioning activities fall within the construction phase and are mostly undertaken in parallel to the last steps of electro-mechanical works. In large scale projects, the first blocs are ready under pre-commissioning while other parts are still being erected.

The pre-commissioning phase includes the following main activities:

· Systematic compliance checks performed on each component of each system, performed in a non-energised state

Testing of appliances, energisation of cables, testing of instrumental circuits, testing of circuit breakers, etc During the pre-commissioning phase, the following tests should be performed, as a minimum requirement:

· Mechanical integrity of the modules with visual inspection and the correct wiring. Thermographic analysis (via drones) can be added at this stage as a best practice

· Verification of the nominal power of the installed system carried out as the sum of the nominal power at STC of all the installed modules

· Verification of the correct operation of all auxiliary services (fire system, rodent protection, forced ventilation of transformers, temperature sensors, UPS systems and related storage systems, lighting systems, etc.)

· Control of all input signals to the SCADA system

· Verification of all power supplies of the auxiliary services of the cabins

· Commissioning of UPS systems and related storage systems, SCADA system and of weather stations and environmental sensors

· Verification of IP addresses on all equipment

· Setting of all alarm thresholds on the equipment

· Verification of the correct polarity and electrical continuity of all the strings

· Check all electrical connections

· Completion and functional verification of the earthing system.

After execution of pre-commissioning activities, the plant will be ready for energisation and for the commissioning activities.

Usually, a detailed checklist covering all components and parts is used to make sure that nothing is missing or incomplete. The works are thoroughly checked through the following items:

· Inverters

· Modules

· Foundations

· PV Module Mounting Structures

· LV and MV Cabling

· Transformers

· Protection, distribution centres and switch gear at the substation

· Combiner boxes

· Civil works

· Low and medium voltage installation works

· Monitoring and security systems

Finally, the checklist should be provided to the Owner and their advisors, together with the compilation of an initial list of construction defects (commonly referred to as a “punch list” or “snagging list”). Counterchecking the EPC service provider checklist and providing own observations and items to add, as defined by the Owner or their advisors, is recommended. . This punch list should include only minor finishing works, the cost of which usually equates to a small percentage of the overall contract value. The contract also needs to specify the timeframe for correcting punch list items, and what the conditions are for granting Provisional Acceptance if punch list items remain unfinished. Once the punch list has been issued by the Owner’s representative a meeting is required between them and the EPC service provider to agree specific resolution for each item and determining if any items are disputed.

Mechanical completion allows for further testing activities to commence. In large scale projects, this is often undertaken by batch and delayed over time, as different parts of the plant are in different stages of construction.

Commissioning, off-grid, and on-grid tests

Commissioning activities

Commissioning activities include operational checks and tests executed on energised electrical systems. The Test Protocol must be agreed between the parties before the start of the tests as part of a Start Up Plan, defined before the start of the Mechanical Completion and Pre-Commissioning activities.

The Test Protocol must respect all the requirements contained in the contract and its basic content should include:

· Results of the visual inspection and related checklist

· Test methodologies

· Instrumentation used for testing

· Test program

· Test conditions

· Test data

· Results of the Pre-Commissioning and Commissioning tests

· The start-up protocols issued for the key components (inverters, transformers, etc.)

This testing aims to verify and certify that the plant has been constructed professionally, according to the pre-established technical prescriptions, and in accordance with the project and any approved variants.

Before the plant is energised, a series of functional tests and measurements should be undertaken as per the reference norm IEC 62446: Grid connected photovoltaic systems. Minimum requirements for system documentation, commissioning tests and inspection for all electrical commissioning.

The testing procedure should be handed over to the Owner prior to commencing the tests, as is usually defined in the EPC contract. This allows the Owner or advisors to review and comment on the testing procedure before implementation. At the end of the commissioning phase, the EPC service provider submits a Test Protocol to the Asset Owner, summarising the results of the Pre-Commissioning and Commissioning tests.

The following test regime shall be performed on all systems. Any test indicating a fault should lead to default rectification and re-testing of the components.

On the AC side, all AC circuits, including AC cables from inverters to transformers, transformers themselves, and main MV switchgear should be tested according to the requirements of IEC 60364-6.

On the DC side, the following tests shall be carried out on the DC circuits and components forming the PV array:

· Continuity of earthing and/or equipotential bonding conductors, where fitted

· Polarity test

· Combiner box test

· String open circuit voltage test

· String circuit current test (short circuit or operational)

· Functional tests

· Insulation resistance of the DC circuits

Some expanded test, not mandatory but often included in the EPC service provider contractor scope, can also be carried out to ensure the best system performance and reliability:

· String I-V curve measurements on a selected sample (10% of the plant at 500W/m²)

It is a best practice to take a pragmatic approach to tests which require minimum levels of irradiance. String tests and thermography should be carried out above certain irradiance minimums. Conducting them at lower levels will provide reduced value from the results. If necessary, some tests may need to be deferred until high season to be valid.

In addition to the above electrical tests, all other equipment should be tested according to the manufacturer’s guidelines and industry best practices to ensure that it functions properly before the energisation of the PV plant. All other equipment and materials include:

· Meteorological stations and monitoring system

· Low voltage installation, civil works, and medium voltage installation

· Security system as well as cyber-security system

· Sanitary system

· Firefighting system

Off-grid testing

The first tests to be conducted are the polarity and combiner tests which need to be undertaken while all strings are still disconnected.

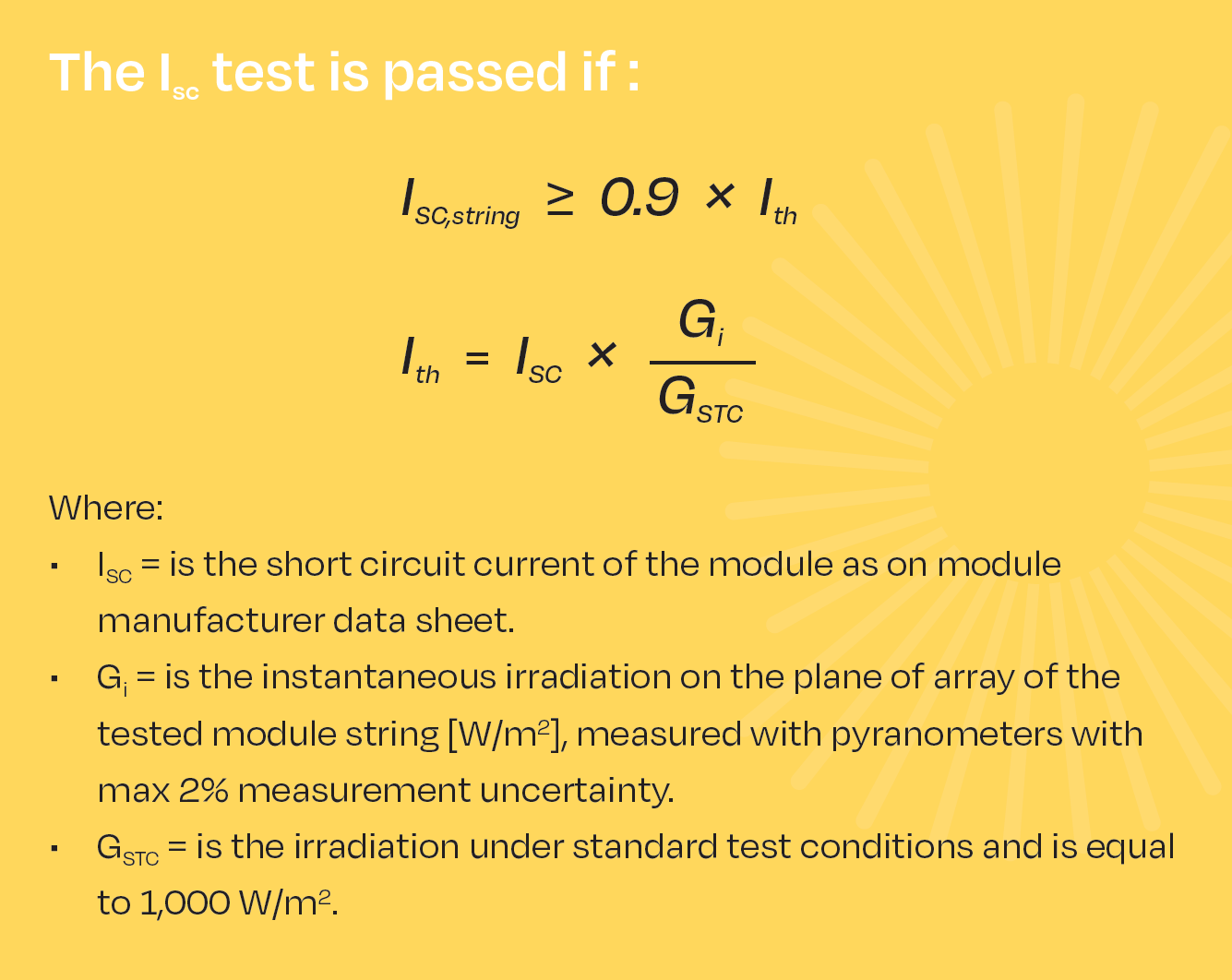

The off-grid tests should include measuring 100% of the open circuit voltage (Voc) and the short circuit current (Isc) of the module strings according to IEC 62446. Prior to starting testing, the Owner must confirm the adequacy of the measurement devices to be used by the EPC service provider (measurement uncertainty, calibration, etc.). A report with measurement results from all the strings will be presented by the EPC service provider in digital form, as an Excel file.

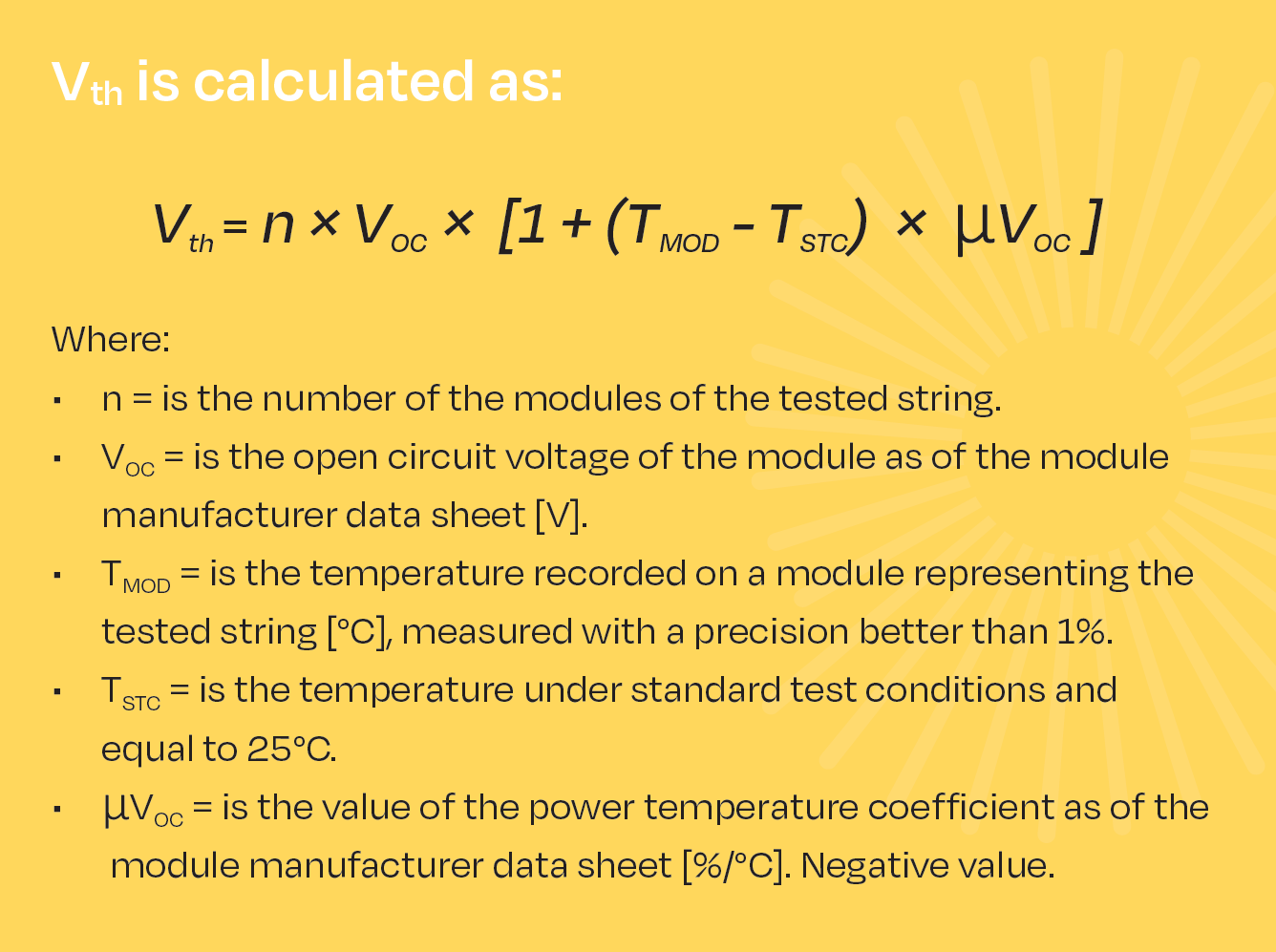

The VOC test is passed if all the VOC, string on the tested strings is within 5% of the expected value derived from the module datasheet. Note that most of the time, the theoretical value should be adjusted with the actual temperature recorded at the time of the measurements as it may be far from STC (25°C).

A commonly used formula is:

Where Vth is the theoretical open circuit voltage for the strings and calculated as follows:

The Isc test is passed if all the Isc,string on the tested strings satisfy the following condition:

It should be noted that the short circuit current test is not intended to detect system underperformance but only used for fault detection in string cabling.

Once the commissioning phase of all the plant sections has been completed and the protocol test issued, the Ready For Start Up (RFSU) certificate of the plant is released by the Asset Owner and then the On-Grid performance and functional tests can be started.

On-grid testing

Once the above off-grid tests have been successfully performed, the PV plant can be energised at inverter level and main switchgear level at the point of interconnection with the grid. The EPC service provider shall demonstrate that the overall system and equipment operates in accordance with the:

· Equipment manufacturer specifications especially for inverters, transformers and MV equipment

· Grid Connection Agreement which should be annexed to the EPC contract, or at least its technical annexes regarding testing and commissioning specifications

· Specifications set out in the EPC Contract

· Any relevant Applicable Standard, mainly IEC 61727 and local grid code

Inverters and transformers shall be commissioned by their manufacturer or an authorised representative of the manufacturer, using the manufacturer’s specified procedures. Commissioning reports shall be issued in a format provided by the manufacturer.

All SCADA system equipment shall be commissioned and tested using the manufacturer’s specified procedures. Tests shall verify the correct operation of the SCADA system, meters, sensors, weather station instruments, and all inverters, while verifying the correct data input logging from trackers (if any), breakers, and other components monitored by the system. The SCADA system shall be fully remotely accessible. A SCADA system commissioning protocol or report shall be provided.

Before energisation, the EPC service provider shall verify the completeness of the substation and the correct installation of all components. A detailed inspection of the substation shall be executed. The testing and commissioning of the PV plant substation connection to the grid system should be performed, including but not limited to:

· MV equipment

· Control and Monitoring System

· Protection system

· Telecommunication system

· Metering devices

· Auxiliary supply equipment and back-up (UPS, diesel, etc.)

In some countries, compliance with the grid code and local safety standards need to be validated by an independent body, and a certificate provided to the grid operator to allow power injection. These compliance tests may also be carried out by the grid operator themselves.

Prior to achieving Provisional Acceptance, it is common practice to carry out module thermography, using aerial inspections as best practice. 100% module thermography should be carried out at this stage according to IEC 62446-3:2017. Issues identified from this inspection will need to be resolved to pass PAC. These inspections and the reports generated should form part of the handover documentation.

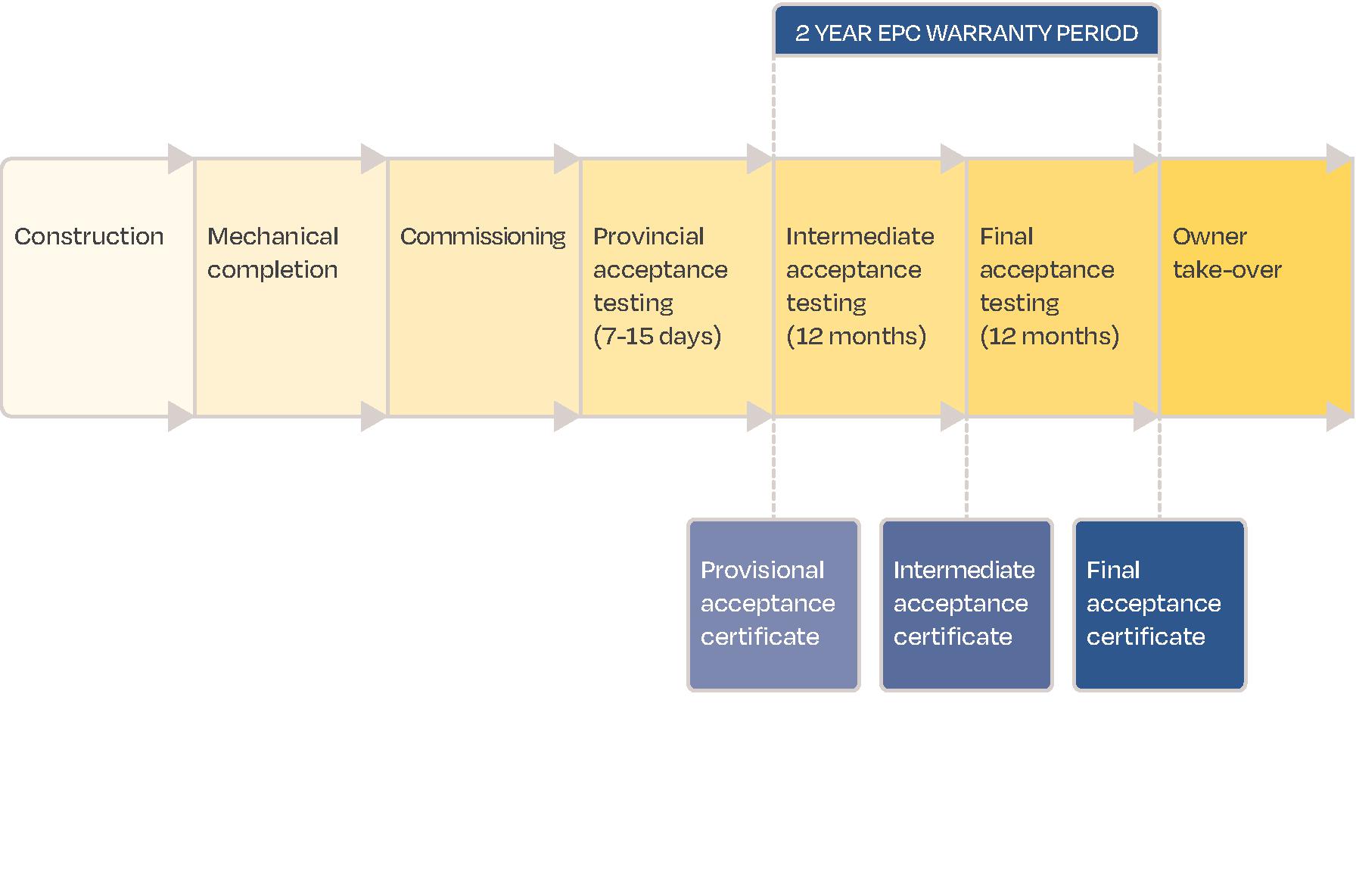

Provisional Acceptance Certificate

The Provisional Acceptance stage marks the end of the construction works and obligations of the EPC service provider. It means the Asset Owner is giving their conditional acceptance of the works. This triggers the two-year standard warranty period, across which the EPC service provider must prove a minimum level of performance from the PV plant, as defined in the contract. At this stage, the plant is also handed over to the Owner and the O&M service provider which may be the same company as the EPC service provider or a third-party.

The conditions for issuing the PAC may differ from contract to contract but the key elements are as follows:

· All commission tests have been successfully completed, including Mechanical Completion, grid connection and energisation of the plant

· The noncritical punch list items have been identified and signature have been provided for corrections. The value of this remaining work does not exceed a certain proportion of the contract price (typically 2-5%)

· The Provisional Acceptance performance tests have been passed (PR but also functional and capacity tests in some cases)

· All equipment and sub-contractor warranties are transferred to the Owner

· The EPC service provider has provided the Owner with the initial or minimum stock of spare parts, as defined in the contract

· All as-built documentation has been provided to the Owner

· Training of the O&M service provider’s teams has been performed and relevant O&M manuals issued

· Liquidated damages (LDs) related to performance or delays have been paid by the EPC service provider

· Any performance security or warranty bond required during the EPC warranty period has been delivered to the Owner

The PAC is signed off by the Asset Owner and, if stipulated in the contract, can also be validated and signed by an independent advisor.

Performance Ratio test

After the functional test, the PV system’s performance, in terms of energy and power, is evaluated in the Start-Up phase. To validate the PV plant performance at Provisional Acceptance phase, the PR test is conducted over a limited period and compared to the guaranteed PR, set based on simulations. The usual duration of PR tests is 7 to 15 days, depending on the contract. From an Owner’s perspective, having the longest testing period possible is recommended, as this helps to check performance in a wide range of climatic conditions, and facilitates comparisons with simulated values.

Usually, the testing period needs to fulfil minimum requirements regarding weather conditions and plant availability such as:

· Minimum irradiance threshold in daily values on a certain number of days (e.g., 8 days over a 15-day period with irradiance greater than 5kWh/m²/day) which should be adapted depending on the season of the test and specific conditions of the project location

· Minimum irradiance threshold on a single day for consecutive hours (e.g., irradiance over 500W/m² during at least 3 consecutive hours in 8 days over a 15-day testing period), also to be adapted to the season and project location

· Total number of testing hours with irradiance above a certain threshold (e.g., 500W/m² for at least 20 hours in a 15-day period)

· Availability should be 100% during the testing period at least at inverter level. Grid availability should also be 100%. The SCADA and the environmental monitoring system must also guarantee 100% availability of data throughout the test period

If the above conditions are not fulfilled within the testing period, it is generally extended until they are. Conditions should be set pragmatically and potentially adjusted to avoid delaying the PAC and leading to difficult negotiations and distrust between parties. The time of year should be considered so that unrealistic thresholds are avoided. The performance tests should ideally be performed during spring as this is usually when performance is at its peak due to better weather conditions. Poor weather conditions can penalise performance compared to simulated values (high summer temperatures, winter shadows or low irradiance).

If the continuity of the test is interrupted due to faults or events related to the malfunction of the plant or one of its parts, the test will be suspended and repeated from the beginning.

If the causes of the interruption are not attributable to the EPC service provider, the test will be suspended and will resume at the end of the interruption.

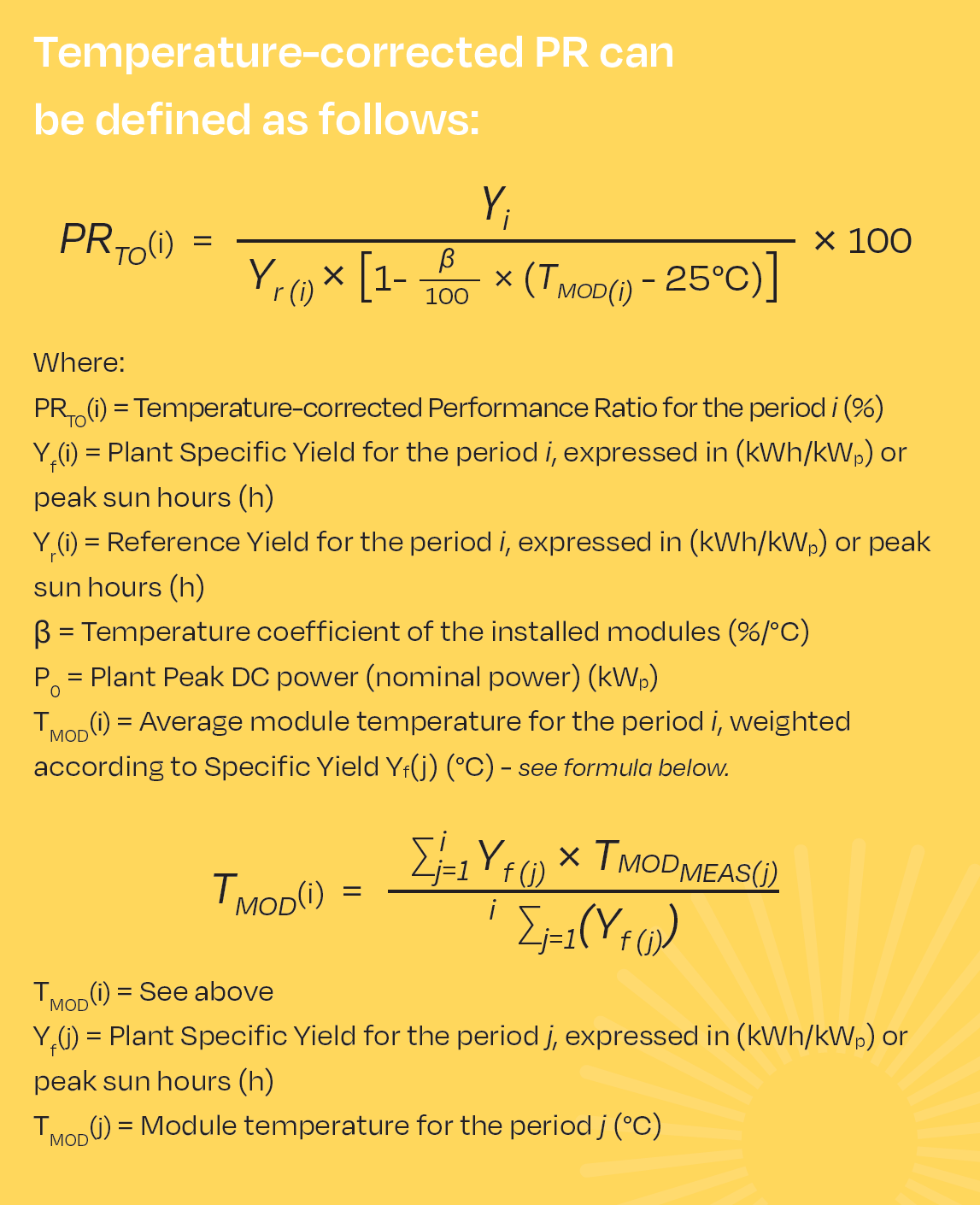

The PR calculations are based on the mathematical definition formula, but each parameter can differ and have its own specifications from contract to contract. It is important to check the consistency of the formula and the input values definitions and measurement rules.

These definitions are based on (Woyte et al. 2014) in line with IEC 61724-1:2017 and are common practice.

For projects located in regions with high temperatures and temperature variability, a temperature-corrected PR methodology needs to be implemented to account for the weather effects.

Finally, the measured PR is compared to the guaranteed value based on the pre-construction yield assessment simulations. A buffer between the simulated value and the guaranteed one is generally used by the EPC service provider. It is important to ensure that the design reference yield has been updated to reflect any changes made during the project. More specifically, the internal and self-shading factor should be checked for accuracy. The guaranteed PR at Provisional Acceptance should be presented as a monthly breakdown of the yearly simulation to ensure accurate comparison with the measured PR for the testing period. Given the short duration of the test, guaranteed PR at Provisional Acceptance is only used as a validation criterion for the Owner’s “take over”. It does not usually trigger performance liquidated damages as they are linked to the results of annual PR tests. If PR is below the guaranteed threshold, corrective action might be undertaken, and testing should be repeated.

Once the PR criteria and any other requirements have been met, the PAC is issued. The project reaches the handover phase, which is the start of the operational phase and O&M activities.

Other tests

In some contracts, complementary tests can be performed at the Provisional Acceptance stage. These tests can reflect the requirements of the energy off taker with the Power Purchase Agreement (PPA), whether or not the system functions, or simply be used as additional quality assurance measures.

To prove the project’s ability to perform to its maximum capacity, a Reliability Test can be undertaken. This means the project must go a certain period (e.g., 7 consecutive days, or 100 consecutive hours) without significant system failure or malfunction. Furthermore, the project must prove that it can run for a certain amount of time without inverter failures or shutdowns, with full availability of AC and DC equipment, and less than a certain threshold (typically 2%) of string or tracking system failure (if any). If a system failure or malfunction occurs, corrective action shall be taken by the EPC service provider and the Reliability Test is restarted the following day.

Additionally, a Capacity Test may be required to prove that the installed capacity can reach the level promised to the off taker. This is usually based on the DC capacity of the plant, calculated based on the peak powers of the installed PV modules, as stated on the manufacturer’s data sheets. Alternatively, this is calculated from the sum of the peak powers of the Flash Test of the PV modules, provided by the manufacturer at shipment. These values must be signed off by an independent third-party.

Start of plant commercial operation

Once all performance tests described in the above sections have been completed, the Asset Owner issues the PAC and commercial production starts (Commercial Operation Date).

To ensure a smooth and efficient handover to operation activities, the Asset Owner should be involved well in advance and participate in the commissioning phase and performance tests. It is also a best practice to involve the operations function of the Asset Owner during the development and engineering phase, so that an O&M perspective can also be taken into consideration.

Comprehensive and detailed as-built documentations (Annex E of the O&M Best Practice Guidelines), manuals and procedures (Annex C “Documentation set accompanying the solar PV plant” of the O&M Best Practice Guidelines) should be part of the training activities. For more information on the Handover to a specialised O&M service provider, please refer to Chapter 10 onHandover to O&M.

Intermediate and Final Acceptance Certificate

There is a standard duration of 24 months (depending on the EPC contract) between the start of the Taking-Over phase to the Defects Notification Period. The EPC service provider is usually responsible for O&M and rectifying any defects that may be identified during this period. However, this may vary from market to market. During this period, a performance warranty based on a guaranteed PR is still in place and can be reviewed on a yearly basis. Annual PR tests are crucial for checking the PV plant performance, as they do not include seasonal bias. For smaller scale projects, this Defects Notification Period can be reduced to 12 months. It is always recommended to carry out PR verifications for at least one full year.

The calculation methodology is different to Provisional Acceptance and should be based on long-term PR tests. The guaranteed performance ratio should be adjusted to account for module degradation over the first and second years of operations. Should the measured PR be above the expected threshold of guaranteed value, then Intermediate and Final Acceptance certificates are issued accordingly. The Owner can then issue a performance certificate and release the performance warranty bond of the EPC service provider. This performance certificate constitutes the full acceptance of the PV plant by the Owner and the release of the Contractor’s obligations.

The guaranteed PR (and therefore the guaranteed energy) takes into account any event causing non-production due to periods of plant downtime. Owner and EPC service provider may agree, and provide for this in the EPC contract, not considering certain special events. In general, it is reasonable to exclude certain events that are outside the control of the EPC service provider (e.g., vandalism, plant stop imposed by the Transmission System Operator) and Force Majeure events.

The EPC contract shall include provisions on how to deal with cases where actual performance is lower than guaranteed performance. These provisions in general are included in the penalty clause.

Where actual performance is lower than guaranteed performance, EPC service provider shall:

· Make all interventions necessary to ensure that guaranteed process parameters are achieved

· Liquidate both the production lost (difference between actual and theoretical production during the period from PAC to the Final Acceptance Test) and the estimate of the lost production expected for the remaining useful life of the plant.

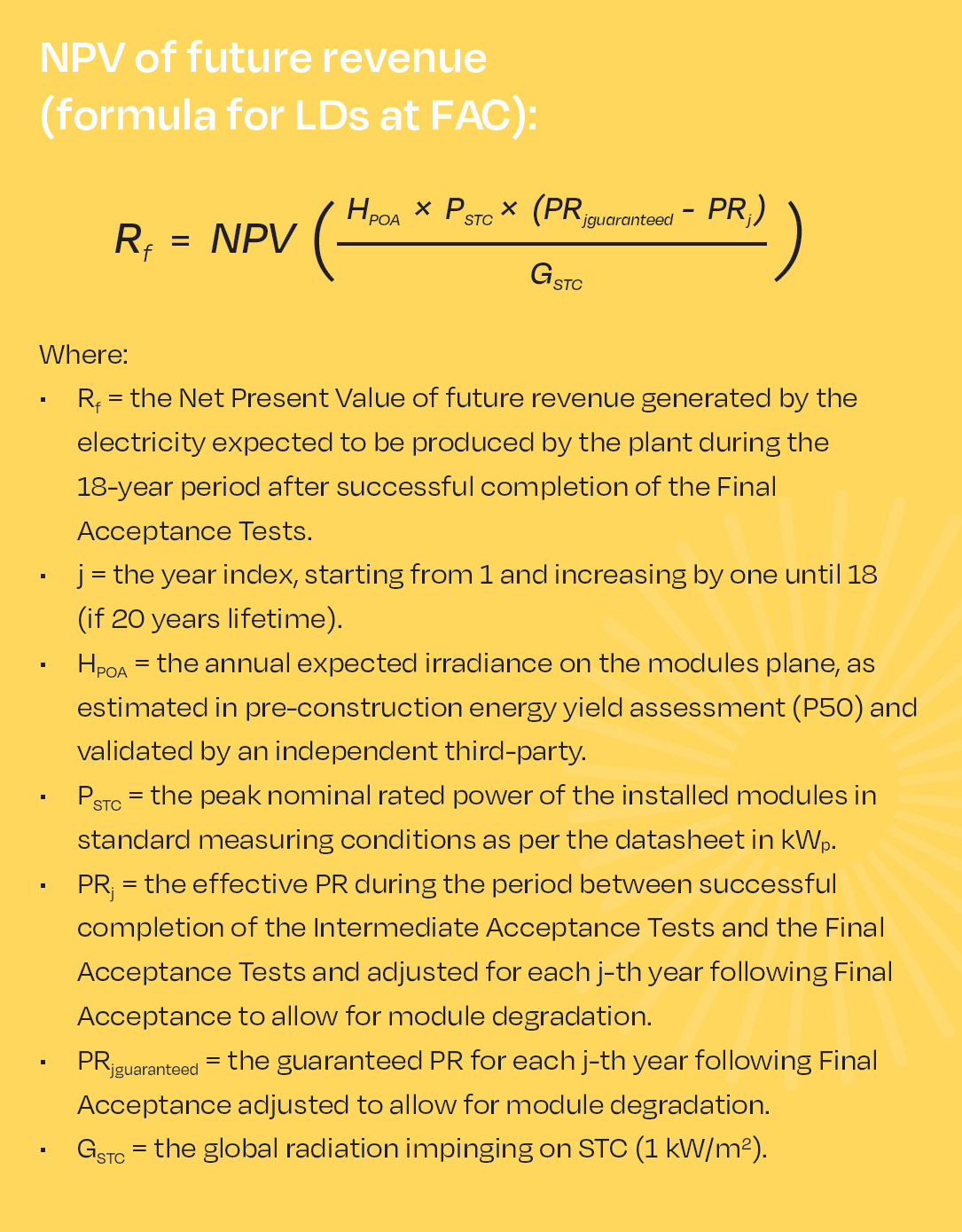

If the measured PR is below the guaranteed levels, the EPC service provider is required to pay performance Liquidates Damages (LDs) up to a certain amount to the Owner for the compensation of revenue losses. During the Intermediate Acceptance phase, the LDs are based on the annual production shortfall and the electricity selling price of the PV plant. During the Final Acceptance phase, the LDs are also calibrated to reflect the loss of revenues that are expected for the full project lifetime or duration of the Power Purchase Agreement. This is usually calculated as the Net Present Value of future revenues shortfall linked to the PR shortfall. Below is an example formula for additional LDs at Final Acceptance:

Other requirements at Final Acceptance stage should include an inspection of the whole plant, including the civil works, electrical infrastructure, every piece of equipment and device installed, and the auxiliary systems, to verify that the EPC service provider is leaving the plant in optimum condition. This should ideally be done in the presence of the Owner and an independent third-party (technical advisor). All existing defects must be solved as a condition for acquiring the Final Acceptance Certificate (FAC). Spare parts can also be replenished in accordance with the O&M contract requirements to ensure a smooth transition between both service providers. Additionally, further testing such as repeated module thermography, across all modules, should be performed as a best practice, preferably using aerial inspections during the period between PAC and FAC. This is to ensure that any issues identified can be resolved before the date for Final Acceptance. It will enable the identification of any early-stage degenerative issues. These activities can be included within the EPC service provider’s scope or under the responsibility of the Owner at their own costs.

After the Final Acceptance Test the Owner shall issue the FAC and shall take over the full responsibility of the plant.

5.2. Construction and operation under EPC warranty

Construction and installation: technical lead - electrical

Please see the previous section "4.1 Development, engineering and procurement - Authorisation".

5.3. Operation

Operation and Maintenance: corrective maintenance

A. Power Plant Operation

Operations concerns remote monitoring, supervision, control of the solar PV power plant, and technical performance optimisation. It also involves subcontracting and coordination of maintenance activities. Power plant operation used to be a more passive exercise in the past, but with increasing grid integration efforts, more active and flexible operation will be required by grid operators. Examples include ordered shutdowns, power curtailment, frequent adjustment of settings such as power factor (source reactive power), frequency tolerances, and voltage tolerances.

The following figure provides an overview of the most important tasks associated with power plant operation.

*It is worth noting that there are several mature industries that have standards (such as ISO 19650:1:2018) for information management repositories and work needs to be done to adopt these.

Documentation Management System (DMS)

Solar PV power plant documentation is crucial for an in-depth understanding of the design, configuration, and technical details of an asset. It is the Asset Owner’s responsibility to provide those documents and, if not available, they should, as best practice, be recreated at the Asset Owner’s cost.

Before assuming any maintenance and/or operational activities, it is important to understand in-depth the technical characteristics of the asset. There are two important aspects related to the management of this information:

· Information type and depth of detail / as-built documentation

· Management and control

Moreover, for quality / risk management and effective operations management a good and clear documentation of contract information, plant information, maintenance activities and asset management are needed over its lifetime. This is what is called here:

· Record control (or records management)

Currently, there are different types of DMS available, along with a series of standards (ISO), that can be implemented. This is an important requirement that would allow any relevant party to trace any changes during the lifetime of the plant’s operation and follow up accordingly (e.g., when the O&M service provider changes, or the teams change, or the plant is sold etc).

Information type and depth of detail / as-built documentation

The documentation set accompanying the solar PV power plant should, as a best practice, contain the documents described in Annex C. The IEC 62446 standard also covers the minimum requirements for as-built documentation.

In general, for optimum service provision and as a best practice, the O&M service provider should have access to all possible documents (from the EPC phase). The Site Operating Plan is the comprehensive document prepared and provided by the plant EPC service povider, which lays out a complete overview of its location, layout, electrical diagrams, components in use and reference to their operating manuals, HSSE rules for the site and certain further topics. All detailed drawings from the EPC service provider need to be handed over to the O&M service provider and being stored safely for immediate access in case of solar PV power plant issues or questions and clarifications with regards to permits and regulation.

When storing documents, thought must be given to accessibility. As a minimum, project documentation should be available in a searchable PDF format to facilitate the identification of key information. Moreover, project drawings, such as the as-built design, should be editable in case they need correcting, or change management processes mean they need to be updated.

Management and control

Regarding the document control, the following guidelines should be followed:

· Documents should be stored either electronically or physically (depending on permits/regulations) in a location with controlled access. Electronic copies should be made of all documents, and these should be searchable and editable

· Only authorised people should be able to view or modify the documentation. A logbook of all the modifications should be kept. As a best practice, logbooks should at a minimum contain the following information:

o Name of person, who modified the document

o Date of modification

o Reason for modification and further information, e.g., link to the work orders and service activities

· Versioning control should be implemented as a best practice. People involved should be able to review past versions and be able to follow through the whole history of the document. The easiest way to ensure this is through using an electronic document management system, which should be considered a best practice

Record control

A key point is that necessary data and documentation are available for all parties in a shared environment and that alarms and maintenance can be documented in a seamless way. Critical to the Operations team is that the maintenance tasks are documented back to and linked with the alarms which might have triggered the respective maintenance activity (work order management system log). Photographs from the site should complement the documentation (when applicable). Tickets (ticket interventions) should be stored electronically and made available to all partners. The Asset Owner should also maintain ownership of these records for future references.

To improve future performance and predictive maintenance, it is crucial to keep a record of past and ongoing O&M data, workflows and alarms. This record should seek to link these elements in a cost-effective way, following an agreed naming convention. This will improve accessibility and allow for easier tracing, facilitating comprehensive lessons learned exercises, and resulting in concrete future recommendations for the client. These analyses should also be recorded.

There should be proper documentation for curtailment periods as well as repair periods when the plant is fully or partly unavailable. This will all be recorded by the monitoring system to measure the energy lost during maintenance activities. For this, having the correct reference values at hand is crucial. For important examples of input records that should be included in the record control, see Annex D.

As in the case of the as-built documentation, all records, data and configuration of the monitoring tool, and any sort of documentation and log that might be useful for proper service provision must be backed up and available when required. This is also important when the O&M service provider changes.

Plant performance monitoring and supervision

The Operations team of the O&M service provider is responsible for continuously monitoring and supervising of the solar PV power plant conditions and its performance. This service is done remotely using monitoring software systems and/or plant operations centres. The O&M service provider should have full access to all data collected from the site to perform data analysis and provide direction to the Maintenance service provider/team. For more information on monitoring tools please refer to SolarPower Europe’s Monitoring Best Practice Checklist (available at www.solarbestpractices.com).

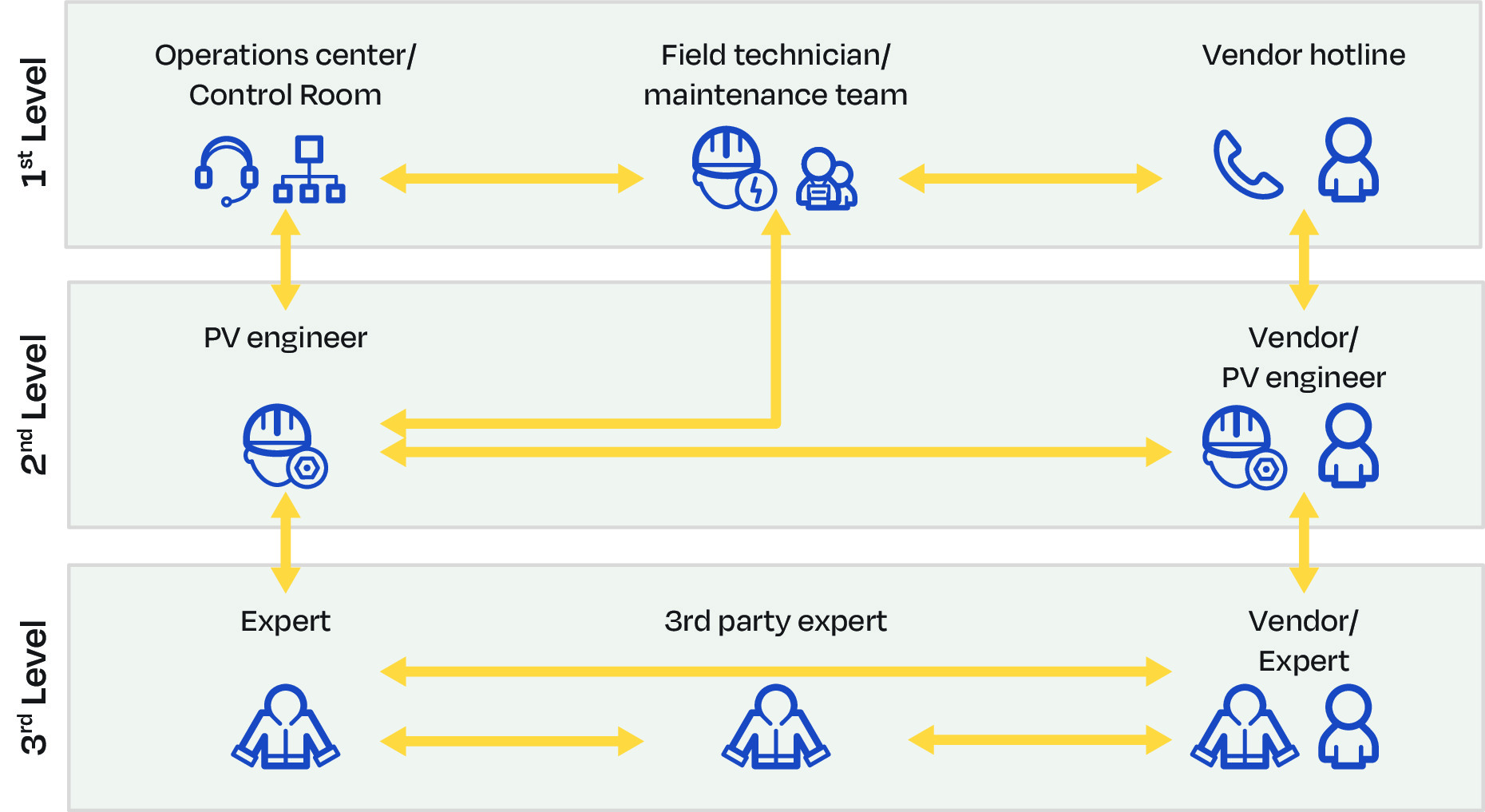

Normally, in Fault Management (Incident Management) several roles and support levels interact:

· With the help of monitoring and its alarms the Operations Center (Control Room) detects a fault. It is responsible for opening a “ticket” and coordinating troubleshooting actions. It collects as much information and diagnostics as possible to establish initial documentation, tries to categorise the issue and, where possible, to resolve it instantly. This is known as 1st Level Support. Then it tracks the incidents until their resolution

· If the fault cannot be sufficiently categorised, the Operations Center may call out a field technician who can be a local electrician or member of the maintenance team. This person will analyse and try to resolve the fault on-site (1st Level Support). Their knowledge and access rights may be not sufficient in some situations, but they can fix most faults to an adequate level. They may also contact the vendor’s hotline to help them with the diagnosis

· If 1st Level Support is not able to resolve the incident right away, it will escalate it to 2nd Level Support. This consists of solar PV engineers or Project/Account Managers who have greater technical skills, higher access permissions, and enough time to analyse the fault in depth. They may be internal or of the vendor’s staff

· If an incident requires special expertise or access, 2nd Level engineers might need to contact experts (in-house or from the vendor or a third party). This is known as 3rd level support. In some organisations the Project/Account Managers can cover both 2nd and 3rd Level Support, based on their seniority and experience

· When the fault is solved, the Operations Center closes the ticket

Besides the data from the site, if a CCTV system is available on-site, the O&M service provider should, as a best practice, be able to access it for visual supervision and also have access to local weather information.

The O&M service provider is responsible for being the main interface between the plant Owner, the grid operator, and the regulator (if applicable) over the lifetime of the O&M contract regarding production data. The Asset Owner should be able to contact the Operations team via a hotline during daytime, when the system is expected to generate electricity. The Operations team is also responsible for coordinating accordingly with the Maintenance service provider/team.

Performance analysis and improvement

The O&M service provider ensures that the performance monitoring is done correctly.

In general, the data should be analysed at the following levels:

1. Portfolio level (group of plants) under control of the O&M service provider (minimum requirement)

2. Plant level (minimum requirement)

3. Inverter level (minimum requirement)

4. String level (as a recommendation)

The analysis should show the required data on the levels listed above and for different time aggregation periods from the actual recording interval up to monthly and quarterly levels.

The analysis should also include the option for having custom alarms based on client specific thresholds such as business plan data or real-time deviations between inverters on-site.

In particular, the agreed KPIs should be calculated and reported. Special attention should be paid to the fact that KPI calculations should take into consideration the contractual parameters between O&M service provider and Asset Owner, to provide an accurate and useful calculation for evaluation and eventually liquidated damages or bonuses.

Optimisation of O&M

An essential part of Operations is the analysis of all the information generated throughout O&M, such as Response Time, and how this correlates to the various classifications of events and root causes. Another vital part of Operations is the analysis of costs incurred for various interventions, categorised into materials and labour. Having such information helps to further optimise the asset by reducing production losses and the cost of O&M itself.

Power plant controls

If applicable, the Operations team can be the point of contact for the grid operator for plant controls. The Operations team will control the plant remotely (if possible) or instruct the qualified maintenance personnel to operate breakers/controls on site. The O&M service provider is responsible for the remote plant controls or emergency shutdown of the plant (if possible) and in accordance with the respective grid operator requirements, regulations and the aggregator’s requirements. The plant control function varies from country to country and in some cases from region to region. The respective solar PV power plant control document for the area details regulations issued by the grid operator and (energy market) regulator.

The Power Plant Controller itself is a control system that can manage several parameters such as active and reactive power and ramp control of solar PV power plants. The set points can normally be commanded either remotely or locally from the Supervisory Control And Data Acquisition system (SCADA). Moreover, the system should be password protected and log all the executed commands. Any executed commands should release real-time notifications to the Operations team.

The following list shows typically controlled parameters in a solar PV power plant:

· Absolute Active Power Control

· Power Factor Control

· Ramp Control (Active and Reactive Power if needed)

· Frequency Control

· Reactive Power Control

· Voltage Control

Power Generation Forecasting

Forecasting services for solar PV power generation are generally offered by operators of solar PV monitoring services. However, external services can also provide this function. When the Asset Owner requires Power Generation Forecasting from the O&M service provider, they could opt for a service level agreement with the forecast provider. Forecasting may have an influence on the contract agreement for electricity dispatching between the Asset Owner and a trading service provider.

The requirements for forecasts may differ from country to country and also depend on the contract agreement for electricity dispatching between the Asset Owner and a trading service provider. Forecast requirements are characterised by the forecast horizon, the time resolution, and the update frequency, all depending on the purpose. For power system or power market related purposes, forecast horizons are typically below 48 hours and the time resolution is 15 minutes to one hour, in line with the programme time unit of the power system or the market. Common products are day-ahead forecasts, intra-day forecasts and combined forecasts. Day-ahead forecasts are typically delivered in the morning for the next day from 0 to 24 and updated once or twice during that day. Intraday forecasts are delivered and updated several times per day for the rest of the day and should be delivered automatically by the forecast provider.

For long-term planning of unit commitment and maintenance decisions, forecasts with longer time horizons are used, typically one week or more.

Solar PV Power Generation Forecasts rely on numerical weather predictions, satellite data and/or statistical forecasting and filtering methods. Most products combine several of these techniques. Good practice requires numerical weather predictions for day-ahead forecasting and a combination with satellite data for intra-day forecasts. In all cases, good practice requires statistical filtering which in turn requires a near-real-time data feed from the monitoring system to the forecast provider. For best practice, the forecast provider should also be informed about scheduled outages and the expected duration of forced outages.

The most common KPIs for forecast quality are the Root Mean Square Error (RMSE) and the Mean Absolute Error (MAE). They are normalised to peak power and not to energy yield.

Grid code compliance

The O&M service provider, and in particular the Operations team is responsible for operating the solar PV power plant in accordance with the respective national grid code. The operator of the grid to which it is connected (either low voltage grid or medium voltage grid or high voltage grid) provides the requirements for power quality, voltage regulation and management of active and reactive power. In some countries (and/or regions) specific grid codes for renewable energy generators have been issued.

Depending on the voltage level of the grid the plant is connected to, the specificities and quality requirements for the solar PV power plant change. Grids with a higher voltage level usually have more specific and demanding requirements.

Most of the grid-connected utility scale solar PV power plants in Europe must undergo an external test to meet the grid operator requirements. These plant tests allow the grid operator to adjust the power output from the solar PV power plant according to the grid capacity and power frequency requirements.

The O&M service provider is expected to be familiar with all the details of the grid code and grid operator requirements. Depending on the regulations, either the grid operator themselves is steering the solar PV power plant controller (with remote signals) or the Operations team is managing the plant controller under the direction of the grid operator.

Management of change

If the design of a solar PV power plant needs to be adjusted after the Commercial Operation Date, the O&M service provider should, as a best practice, be involved by the Asset Owner and the EPC service provider. They can even be a main contributor, if not the leader, of this change process. Reasons for such changes can be motivated by non-compliance of the solar PV power plant with the capacity predicted by the EPC service provider, by regulation change (introduction of new solar PV power plant controls regulations), by the unavailability of spare parts or components, or for an upgrade to the solar PV power plant. These events can trigger new design works, procurement and installation of new equipment and adjustment of O&M procedures and/or documentation. It may also impact certain performance commitments or warranties provided by the O&M service provider, which will need to be adjusted.

The O&M service provider should be involved in changes to the solar PV power plant from the beginning. Concepts, design works, and execution need to be coordinated with ongoing O&M activities. Any changes should also be reflected in the plant SCADA and monitoring systems. For data continuity and long-term analysis, the monitoring system should be able to trace all changes of electrical devices. This should include documentation of inverter replacement date, manufacturer and type, and serial number in a structured way for further analysis (e.g., spare part management, Predictive Maintenance analysis). The monitoring of replaced devices will also help the O&M service provider verify that the new component is correctly configured and is sending high quality data. Adjustments to the Site Operating Plan, the Annual Maintenance Plan and the Annual Maintenance Schedule need to be applied and the O&M service provider needs to familiarise the O&M staff with the operating manuals of the new equipment. These types of changes will have an impact on Spare Parts Management and inventory (replacement). Depending on the significance of the change, the O&M annual fee might need to be adjusted.

It is advisable that the O&M service provider lead these sorts of change processes. The O&M service provider is the trusted partner of the Asset Owner and should advise the Owner when they are making decisions on changes to the plant. In the case of major changes, the Owner should also consider informing lenders about the decision process and provide concepts, proposals, calculations and updates.

The fixed O&M fee does not usually cover change services. The Asset Owner and the O&M service provider should manage changes in a formalised way. This procedure should include the following steps: description of proposed change (including time plan, costs, consequences, and alternatives), authorisation of the change by the Asset Owner, realisation of the change, documentation by the O&M service provider and acceptance.

Power plant security

It is important that the solar PV power plant, or key areas of it, are protected from unauthorised access. This serves the dual purpose of protecting the plant’s equipment and keeping members of the public safe. Unauthorised access may be accidental with people wandering into the plant without realising the dangers, or it may be deliberate for the purposes of theft or vandalism.

Together with the O&M service provider and the security service provider, the Asset Owner must put in place a Security Protocol in case an intrusion is detected.

In most countries there are strict legal requirements for security service providers. Therefore, solar PV power plant security should be ensured by specialised security service providers subcontracted by the O&M service provider. The security service provider will be responsible for the proper functioning of all the security equipment including intrusion and surveillance systems. They are also responsible for processing alarms from the security system by following the Security Protocol and the use of the surveillance systems installed on site. The security system provider will be also responsible for any site patrolling or other relevant services. The security service provider should also assume liability for the security services provided. The O&M service provider will coordinate with the security service provider and may choose to act as an intermediary with the Asset Owner.

A security system may be formed of simple fencing or barriers but may also include alarm detection and alerting systems and remote closed-circuit television (CCTV) video monitoring. If solar PV power plants have CCTV systems in place, an access protocol would be required when reactive and planned works are carried out. This will ensure that authorised access is always maintained. This can be done by way of phone with passwords or security pass codes, both of which should be changed periodically.

For additional security and in high-risk areas it is advisable to have a backup communication line installed (often, the first thing that gets damaged in case of vandalism is communication with the surveillance station) as well as an infrastructure for monitoring connectivity and communication with the security system. As well as any remote monitoring, it is likely that provision for onsite attendance is required when significant events occur. Processes for liaising with local emergency services should be considered.

Within the solar plant, there may also be additional areas with restricted access, for example locations containing High Voltage equipment. When authorising access to the parks it is important that all workers and visitors are appropriately informed of the specific access and security arrangements and where they should or should not be. Warning signs and notices can form an important part of this and may be compulsory depending on local regulations.

As well as the general security of the site over the lifetime of the park, particular attention should be made to periods of construction or maintenance when usual access arrangements may be different. It is important that security is always maintained particularly when there are activities that may be of more interest to members of the public or thieves.

The Asset Owner will likely have insurance policies in place directly or indirectly and these will be dependent on certain levels of security and response being maintained. Failure to meet these may have important consequences in the case of an accident or crime.

Reporting and Technical Asset Management

The Operations team is responsible for providing periodic reporting to the AM or directly to the Asset Owner. In many cases, the Operations team also assumes further TAM responsibilities.

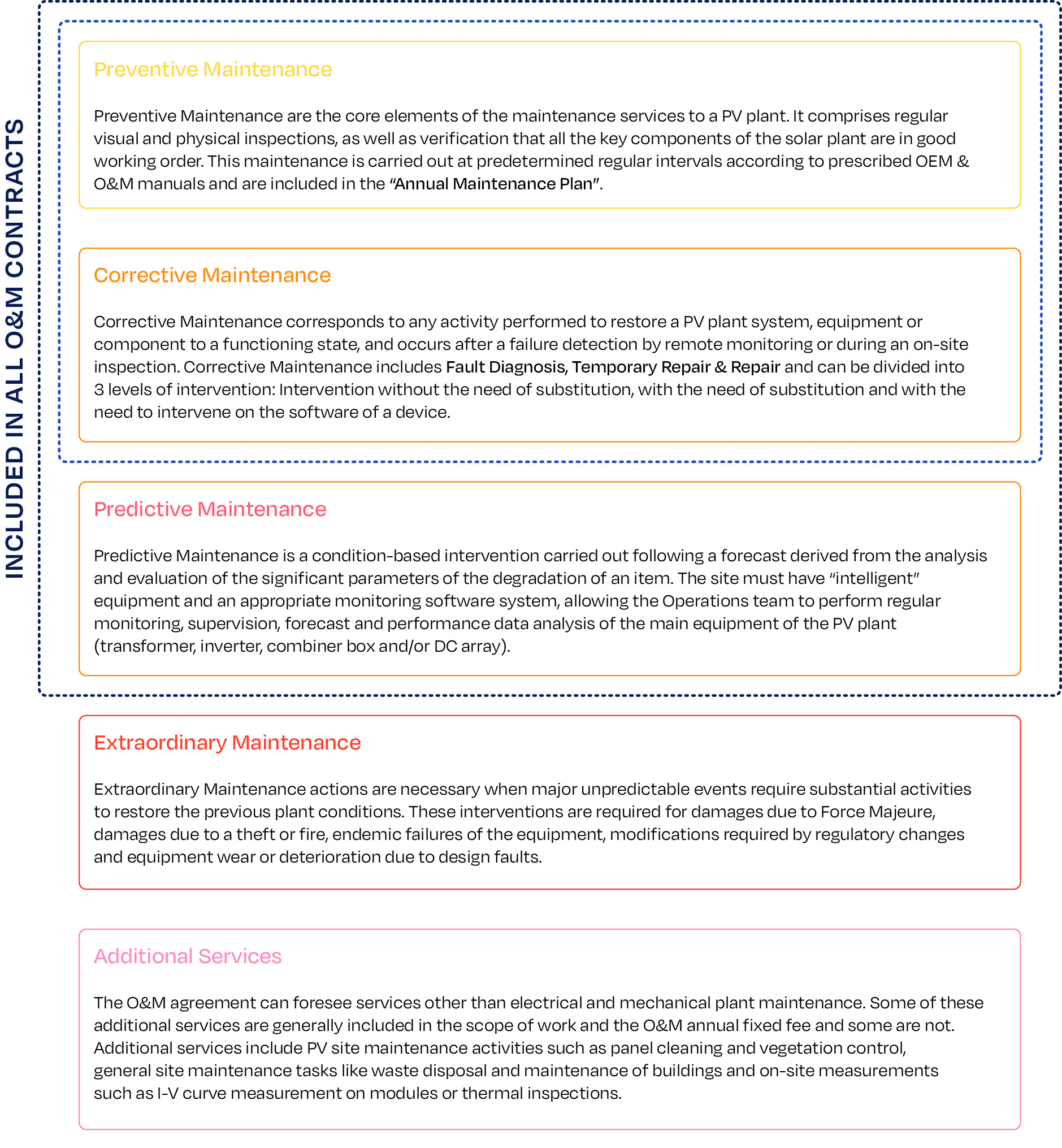

B. Power Plant Maintenance

Maintenance is usually carried out on-site by specialised technicians or subcontractors, in close coordination with the Operations team’s analyses. In modern solar PV power plants, automation of maintenance tasks is becoming more prevalent. However, this practice is still developing and is not widespread currently. The following figure provides an overview of the four main types of power plant maintenance.

Preventive Maintenance

Preventive Maintenance activities are the core element of the maintenance services to a solar PV power plant. It comprises regular visual and physical inspections, as well as verification activities.

The maintenance of all key components is carried out at predetermined intervals or at least according to prescribed OEM and O&M manuals. These are included in a detailed Annual Maintenance Plan which provides an established time schedule with a specific number of iterations for carrying out the maintenance.

It must also maintain the equipment and component warranties in place and reduce the probability of failure or degradation. The activities must also be consistent with respective legal issues such as national standards for periodic inspection of certain electrical components. It should be noted that the various maintenance activities that an O&M service provider is expected to carry out require personnel qualified to carry them out. The O&M service provider must ensure that they have the appropriate range of skills available to fulfil their contractual obligations (for more information on maintenance activities and the skills they require, see Annex B of the O&M Guidelines and Annex A of the Lifecycle Quality Guidelines). The O&M contract should include this scope of services and each task frequency.

It is the responsibility of the O&M service provider to prepare the task plan, according to the time intervals in the contract.

The “Annual Maintenance Plan” (see Annex E or download it from www.solarpowereurope.org) developed as an attachment of this report includes a list of regular inspections per equipment (e.g., module, inverter etc) and per unit of equipment (e.g., sensors, fuses etc).

An example of Preventive Maintenance is thermographic inspection which aims to identify defective panels on a solar PV power plant. Indeed, several categories of anomalies (hot spots, hot strips, moisture ingress, soling, etc.) can occur, significantly reducing the whole plant productivity. Relevant inspection procedures are performed either by operators with handheld cameras or using remotely piloted drones or piloted aircraft equipped with dedicated thermal and optical payloads.

Preventive Maintenance also includes ad-hoc replacement of parts of inverters or sensors. In general, it is important to follow detailed Preventive Maintenance procedures, which are agreed upon in the Annual Maintenance Plan.

In cases where downtime is necessary to perform Preventive Maintenance, its execution during the night would be considered best practice as the overall power generation is not affected.

Corrective Maintenance

Corrective Maintenance covers the activities performed by the Maintenance team to restore a solar PV power plant system, equipment or component to a status where it can perform the required function. Corrective Maintenance takes place after a failure detection either by remote monitoring and supervision or during regular inspections and specific measurement activities (see Annex E).

Corrective Maintenance includes three activities:

1. Fault Diagnosis also called troubleshooting to identify and locate the cause of the fault

2. Temporary Repair, to restore the required function of a faulty item for a limited time, until a full repair is carried out

3. Full repair, to restore the required function permanently

In cases where the solar PV power plant or segments thereof need to be taken offline, Corrective Maintenance should be performed at night or during periods of low irradiation as the overall power generation is not affected.

A key aspect of corrective maintenance is to be able to track failures to their root cause. This is most often a problematic manufacturer/model/serial number but may also be linked to installation errors or environmental conditions such as temperature inside enclosures. Corrective Maintenance processes should also track the efficacy of responses to problems (what fixes the problem reliably?).

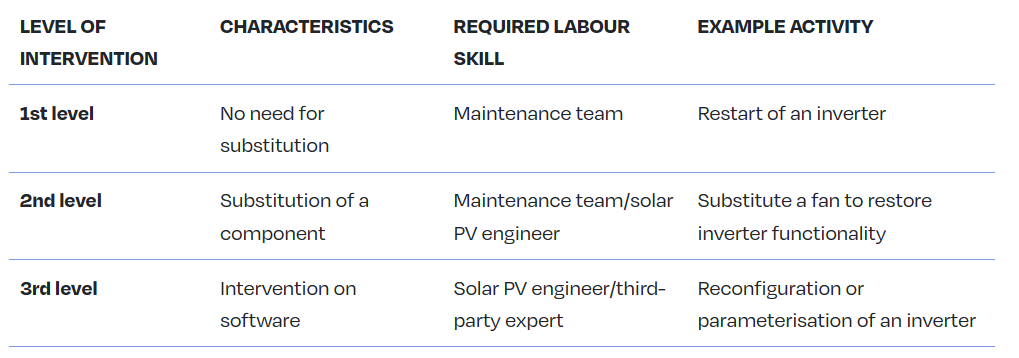

Corrective Maintenance can be divided into three levels of intervention to restore the functionality of a device, that could be included in the O&M agreement or billed separately on hourly rates:

3rd level activities could be included in the O&M agreement or billed separately to it, depending on the specific scope of work agreed between the parties. Generally, however, this intervention is excluded by the contractual scope of work, especially when the device manufacturers’ maintenance team or third-party licensed company needs to intervene.

Interventions for reconditioning, renewal, and technical updating, save for the cases where those actions are directly included in the scope of the contract, should be excluded from Corrective Maintenance, and included in the Extraordinary Maintenance.

The scope of Corrective Maintenance activities and its “border” or definition with respect to Preventive Maintenance requires specific attention and it should be properly defined in the Maintenance contract. For an easier comprehension, an example is presented below:

· A cable termination tightening activity using a torque device for correct fixation should be under the Preventive Maintenance scope of works, but depending on the quantity and/or frequency, it could be considered a Corrective Maintenance activity. The Annual Maintenance plan therefore states the extent of each planned activity.

Usually, Corrective Maintenance work must be accomplished within the contractually agreed minimum Response Times.

Contractual agreements can foresee that the included Corrective Maintenance will be capped on a per year basis. Depending on whether the Asset Owner is a purely financial investor or an energy producer (e.g. utility or IPP) the requirements for coverage under the Corrective Maintenance will vary.

Predictive Maintenance

Predictive Maintenance is a special service provided by O&M service providers who follow best practices principles. It is defined as a condition-based maintenance carried out following a forecast derived from the analysis and evaluation of the significant parameters of the degradation of the item (according to EN 13306). A prerequisite for a good Predictive Maintenance is that the devices on-site can provide information about their state, in such a way that the O&M service providers can evaluate trends or events that signal deterioration in a device. As a best practice, the device manufacturer should provide a complete list of status and error codes produced by the device, together with the detailed description of their meaning and their impact on the functioning of the device. Additionally, a standardisation of status and error codes through inverters and dataloggers from the same brand should be followed and, in the future, this standardisation should be common to all manufacturers.

Stakeholders who want to benefit from Predictive Maintenance should, as a best practice, select “intelligent” equipment set with sufficient sensors, and opt for a monitoring software system that provides basic trending and comparison (timewise or between components and even between solar PV sites) functionalities (minimum requirement).

The Operations team of the O&M service provider enables Predictive Maintenance thorough continuous or regular monitoring, supervision, forecast and performance data analysis (e.g., historical performance and anomalies) of the solar PV power plant (at the DC array, transformer, inverter, combiner box or/and string level). This can identify subtle trends that would otherwise go unnoticed until the next round of circuit testing or thermal imaging inspection and that indicate upcoming component or system failures or underperformance (e.g., at solar PV modules, inverters, combiner boxes, trackers, etc. level).

Before deciding which Predictive Maintenance actions to recommend, the Operations team should implement and develop procedures to effectively analyse historical data and faster identify behaviour changes that might jeopardise systems performance. These changes of behaviour are usually related to the pre-determined or unpredicted equipment degradation process. For this reason, it is important to define and to monitor all significant parameters of wear-out status, based on the sensors installed, algorithms implemented into the supervision system and other techniques.

Following such analysis, the Maintenance team can implement Predictive Maintenance activities to prevent any possible failures which can cause safety issues and energy generation loss.