Onboarding Best Practice Guidelines

Maintenance

11.1. Operation under ownership

11.1.1. Operating and maintaining PV modules

Basic knowledge about the installed product

Power Plant Maintenance

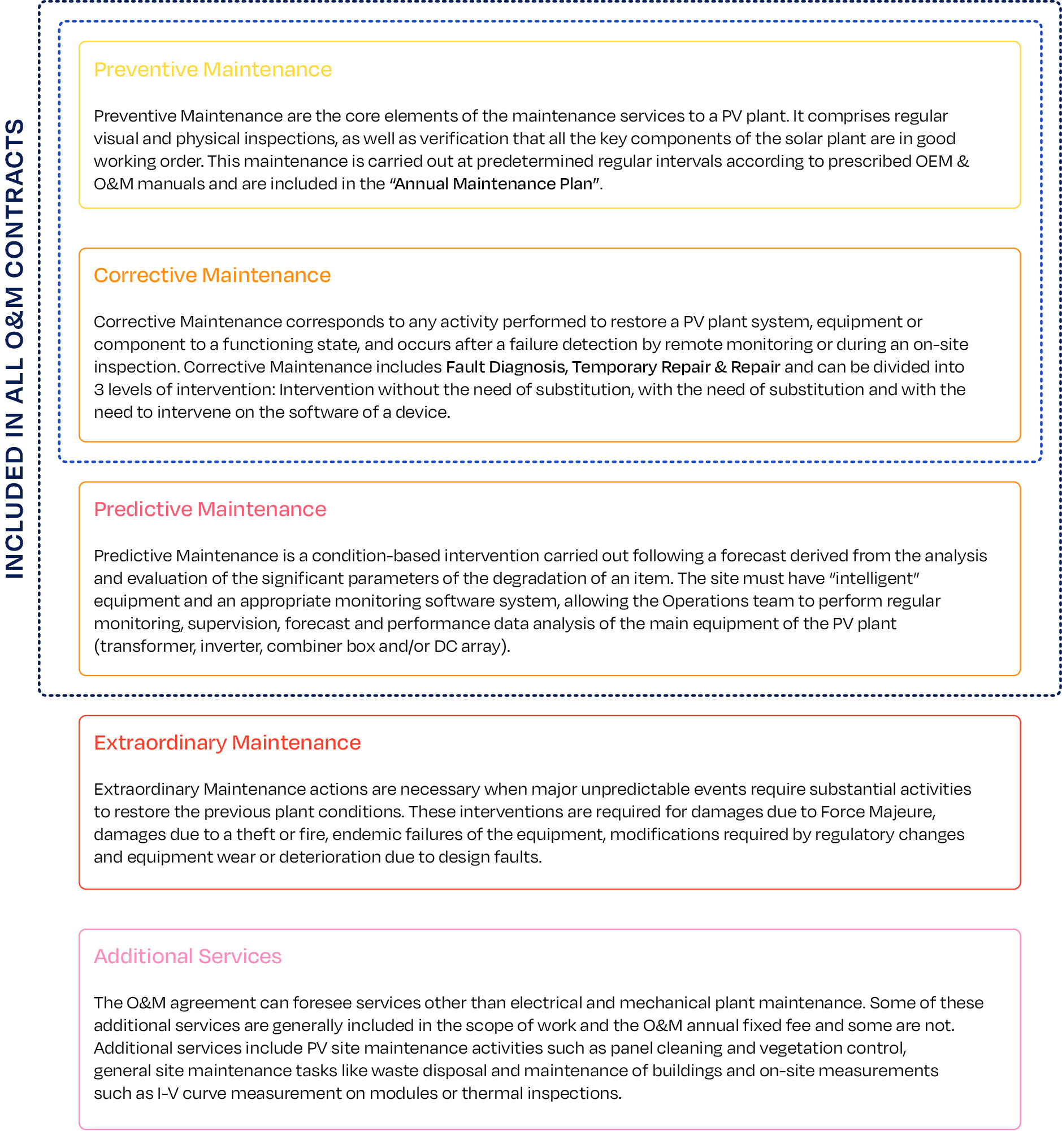

Maintenance is usually carried out on-site by specialised technicians or subcontractors, in close coordination with the Operations team’s analyses. In modern solar PV power plants, automation of maintenance tasks is becoming more prevalent. However, this practice is still developing and is not widespread currently. The following figure provides an overview of the four main types of power plant maintenance.

Preventive Maintenance

Preventive Maintenance activities are the core element of the maintenance services to a solar PV power plant. It comprises regular visual and physical inspections, as well as verification activities.

The maintenance of all key components is carried out at predetermined intervals or at least according to prescribed OEM and O&M manuals. These are included in a detailed Annual Maintenance Plan which provides an established time schedule with a specific number of iterations for carrying out the maintenance.

It must also maintain the equipment and component warranties in place and reduce the probability of failure or degradation. The activities must also be consistent with respective legal issues such as national standards for periodic inspection of certain electrical components. It should be noted that the various maintenance activities that an O&M service provider is expected to carry out require personnel qualified to carry them out. The O&M service provider must ensure that they have the appropriate range of skills available to fulfil their contractual obligations (for more information on maintenance activities and the skills they require, see Annex B of the O&M Guidelines and Annex A of the Lifecycle Quality Guidelines). The O&M contract should include this scope of services and each task frequency.

It is the responsibility of the O&M service provider to prepare the task plan, according to the time intervals in the contract.

The “Annual Maintenance Plan” (see Annex E or download it from www.solarpowereurope.org) developed as an attachment of this report includes a list of regular inspections per equipment (e.g., module, inverter etc) and per unit of equipment (e.g., sensors, fuses etc).

An example of Preventive Maintenance is thermographic inspection which aims to identify defective panels on a solar PV power plant. Indeed, several categories of anomalies (hot spots, hot strips, moisture ingress, soling, etc.) can occur, significantly reducing the whole plant productivity. Relevant inspection procedures are performed either by operators with handheld cameras or using remotely piloted drones or piloted aircraft equipped with dedicated thermal and optical payloads.

Preventive Maintenance also includes ad-hoc replacement of parts of inverters or sensors. In general, it is important to follow detailed Preventive Maintenance procedures, which are agreed upon in the Annual Maintenance Plan.

In cases where downtime is necessary to perform Preventive Maintenance, its execution during the night would be considered best practice as the overall power generation is not affected.

Corrective Maintenance

Corrective Maintenance covers the activities performed by the Maintenance team to restore a solar PV power plant system, equipment or component to a status where it can perform the required function. Corrective Maintenance takes place after a failure detection either by remote monitoring and supervision or during regular inspections and specific measurement activities (see Annex E).

Corrective Maintenance includes three activities:

1. Fault Diagnosis also called troubleshooting to identify and locate the cause of the fault

2. Temporary Repair, to restore the required function of a faulty item for a limited time, until a full repair is carried out

3. Full repair, to restore the required function permanently

In cases where the solar PV power plant or segments thereof need to be taken offline, Corrective Maintenance should be performed at night or during periods of low irradiation as the overall power generation is not affected.

A key aspect of corrective maintenance is to be able to track failures to their root cause. This is most often a problematic manufacturer/model/serial number but may also be linked to installation errors or environmental conditions such as temperature inside enclosures. Corrective Maintenance processes should also track the efficacy of responses to problems (what fixes the problem reliably?).

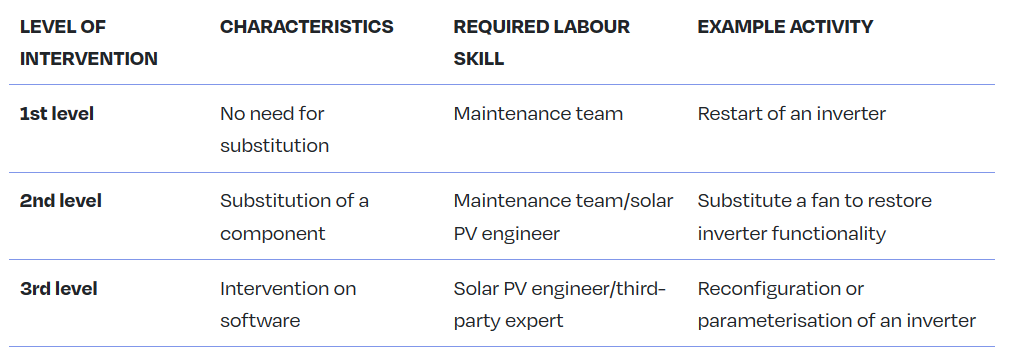

Corrective Maintenance can be divided into three levels of intervention to restore the functionality of a device, that could be included in the O&M agreement or billed separately on hourly rates:

3rd level activities could be included in the O&M agreement or billed separately to it, depending on the specific scope of work agreed between the parties. Generally, however, this intervention is excluded by the contractual scope of work, especially when the device manufacturers’ maintenance team or third-party licensed company needs to intervene.

Interventions for reconditioning, renewal, and technical updating, save for the cases where those actions are directly included in the scope of the contract, should be excluded from Corrective Maintenance, and included in the Extraordinary Maintenance.

The scope of Corrective Maintenance activities and its “border” or definition with respect to Preventive Maintenance requires specific attention and it should be properly defined in the Maintenance contract. For an easier comprehension, an example is presented below:

· A cable termination tightening activity using a torque device for correct fixation should be under the Preventive Maintenance scope of works, but depending on the quantity and/or frequency, it could be considered a Corrective Maintenance activity. The Annual Maintenance plan therefore states the extent of each planned activity.

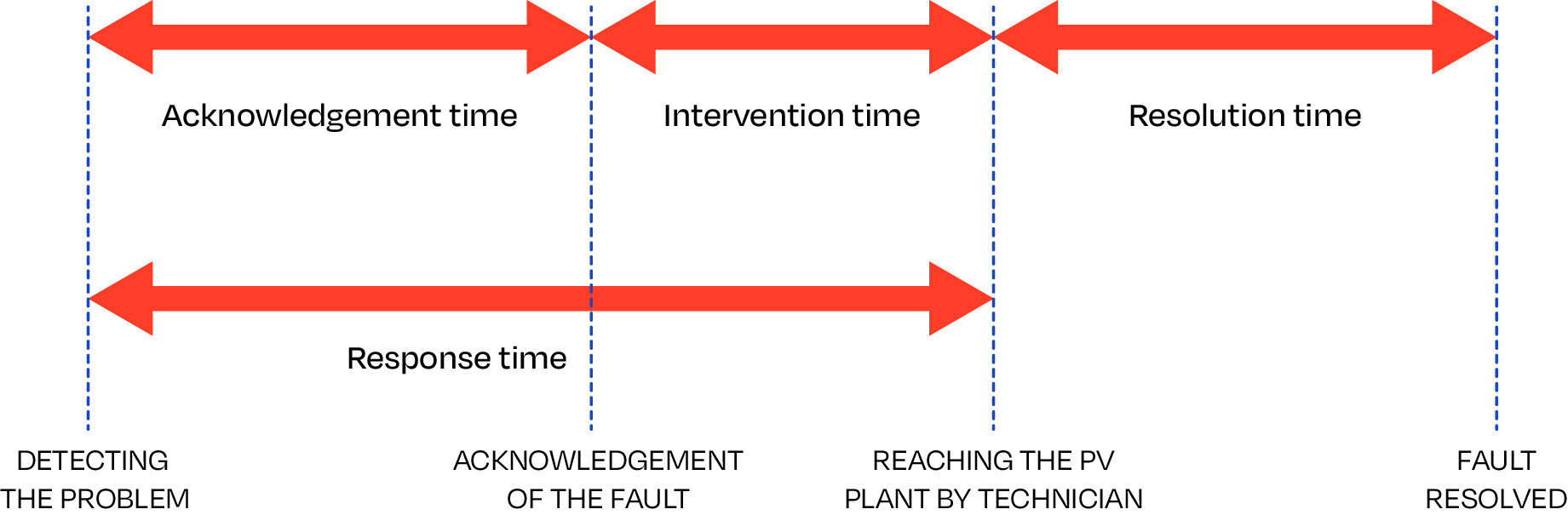

Usually, Corrective Maintenance work must be accomplished within the contractually agreed minimum Response Times.

Contractual agreements can foresee that the included Corrective Maintenance will be capped on a per year basis. Depending on whether the Asset Owner is a purely financial investor or an energy producer (e.g. utility or IPP) the requirements for coverage under the Corrective Maintenance will vary.

Predictive Maintenance

Predictive Maintenance is a special service provided by O&M service providers who follow best practices principles. It is defined as a condition-based maintenance carried out following a forecast derived from the analysis and evaluation of the significant parameters of the degradation of the item (according to EN 13306). A prerequisite for a good Predictive Maintenance is that the devices on-site can provide information about their state, in such a way that the O&M service providers can evaluate trends or events that signal deterioration in a device. As a best practice, the device manufacturer should provide a complete list of status and error codes produced by the device, together with the detailed description of their meaning and their impact on the functioning of the device. Additionally, a standardisation of status and error codes through inverters and dataloggers from the same brand should be followed and, in the future, this standardisation should be common to all manufacturers.

Stakeholders who want to benefit from Predictive Maintenance should, as a best practice, select “intelligent” equipment set with sufficient sensors, and opt for a monitoring software system that provides basic trending and comparison (timewise or between components and even between solar PV sites) functionalities (minimum requirement).

The Operations team of the O&M service provider enables Predictive Maintenance thorough continuous or regular monitoring, supervision, forecast and performance data analysis (e.g., historical performance and anomalies) of the solar PV power plant (at the DC array, transformer, inverter, combiner box or/and string level). This can identify subtle trends that would otherwise go unnoticed until the next round of circuit testing or thermal imaging inspection and that indicate upcoming component or system failures or underperformance (e.g., at solar PV modules, inverters, combiner boxes, trackers, etc. level).

Before deciding which Predictive Maintenance actions to recommend, the Operations team should implement and develop procedures to effectively analyse historical data and faster identify behaviour changes that might jeopardise systems performance. These changes of behaviour are usually related to the pre-determined or unpredicted equipment degradation process. For this reason, it is important to define and to monitor all significant parameters of wear-out status, based on the sensors installed, algorithms implemented into the supervision system and other techniques.

Following such analysis, the Maintenance team can implement Predictive Maintenance activities to prevent any possible failures which can cause safety issues and energy generation loss.

For efficient Predictive Maintenance, a certain level of maturity and experience is required, which is at best a combination of knowledge of the respective system’s performance, related equipment design, operation behaviour, and relevant the service provider’s track record. Normally it is a process that starts after the implementation of an appropriate monitoring system and the recreation of a baseline. This baseline will then represent the entire solar PV system operation, how different pieces of equipment interact with each other, and how the system reacts to “environmental” changes.

Predictive Maintenance has several advantages, including:

- Optimising the safety management of equipment and systems during their entire lifetime

- Helping to anticipate maintenance activities (both corrective and preventive)

- Delaying, eliminating and optimising some maintenance activities

- Reducing time for repairs and optimising maintenance and Spare Parts Management costs

- Reducing spare parts replacement costs

- Increasing availability, energy production and performance of equipment and systems

- Reducing emergency and non-planned work

- Improving predictability

The following two specific examples show how Predictive Maintenance might be implemented.

Example 1 – An O&M service provider signs a new contract for a solar PV power plant equipped with central inverters. Analysing its backlog of maintenance, the O&M service provider knows that these inverters showed signs of power loss due to overheating at several points in the past. This might be related to problems in the air flow, filter obstructions, fans, or environmental changes (high temperature during summer). A decision was taken to monitor the temperature of IGBTs (Insulated-Gate Bipolar Transistors). An “air flow inspection” was performed, prior to any emergency action being required, to determine whether power loss was related to air flow. This type of activity is a condition-based inspection performed after the detection of a change in a significant parameter. It is also considered as a type of Predictive Maintenance. The final purpose is to identify if, for example, the ventilation systems will need some upgrade, replacement, or if there is any type of air flow obstruction or even if a filter replacement or cleaning is required.

Example 2 – Predictive Maintenance for optimised hardware replacement cycle relying on big data analytics or artificial intelligence. For more information on this innovation.

Extraordinary Maintenance

Extraordinary Maintenance actions are necessary when major unpredictable events take place in the plant that require substantial activities and works to restore the previous plant conditions (or any maintenance activity generally not covered or excluded from the O&M Contract).

“Force Majeure” events affecting solar PV power plants include high winds, flooding, hurricanes, tornados, hail, lightning, and any number of other severe weather events. Extraordinary Maintenance associated with severe weather include safety shutdown, inspection to document damage, electrical testing (integrity of circuits and grounding), remove/repair/replace decisions, and recommissioning confirming proper operation and documenting changes made during repairs.

Generally, these activities are billed separately in the O&M contract and are managed under a separate order. It is advisable that the O&M contract includes the rules agreed among the parties to prepare the quotation and to execute the works. Both a “lump sum turn-key” or a “cost-plus” method can be used for such purposes.

Extraordinary Maintenance interventions are required for:

· Damages that are a consequence of a Force Majeure event

· Damages resulting from theft or fire

· Serial defects or endemic failures on equipment, occurring suddenly and after months or years from plant start-up

· Modifications required by regulatory changes

In cases where the O&M service provider and the EPC service provider are different entities, the following occurrence should also be considered as Extraordinary Maintenance:

· Major issues that the O&M service provider becomes aware of during its ordinary activity. These could be defects or other problems that are not a consequence of equipment wear or deterioration and can be reasonably considered to have been caused by design mistakes (e.g., “hidden” defects that require re-engineering)

Although not necessarily maintenance interventions, revamping and repowering can also be included in the Extraordinary Maintenance list in the O&M agreement, or at least managed with the same rules.

After the approval by the Asset Owner of the O&M service provider’s proposal, activities may commence, subject to availability of the required equipment and special machinery (if required).

The potential loss of energy between the event occurrence and full repair is very difficult to determine in the SPV financial model. However, many of the above events can be reimbursed to the Asset Owner by the insurance company under any “All Risk Insurance” coverage that is in place. Relevant conditions and requirements according to the insurance policies of the Asset Owner need to be shared with the O&M service provider.

Best Practices of O&M agreements regarding Extraordinary Maintenance activities include:

· General rules to quantify price and to elaborate a schedule to perform repair activities, and the right of the Asset Owner to ask for third party quotations to compare to the quotation of the O&M service provider. In this case a “right-to-match” option should be granted to the O&M service provider

· The obligation for the Asset Owner to have in place a consistent “All Risk Property” Insurance including loss of profit

Additional services

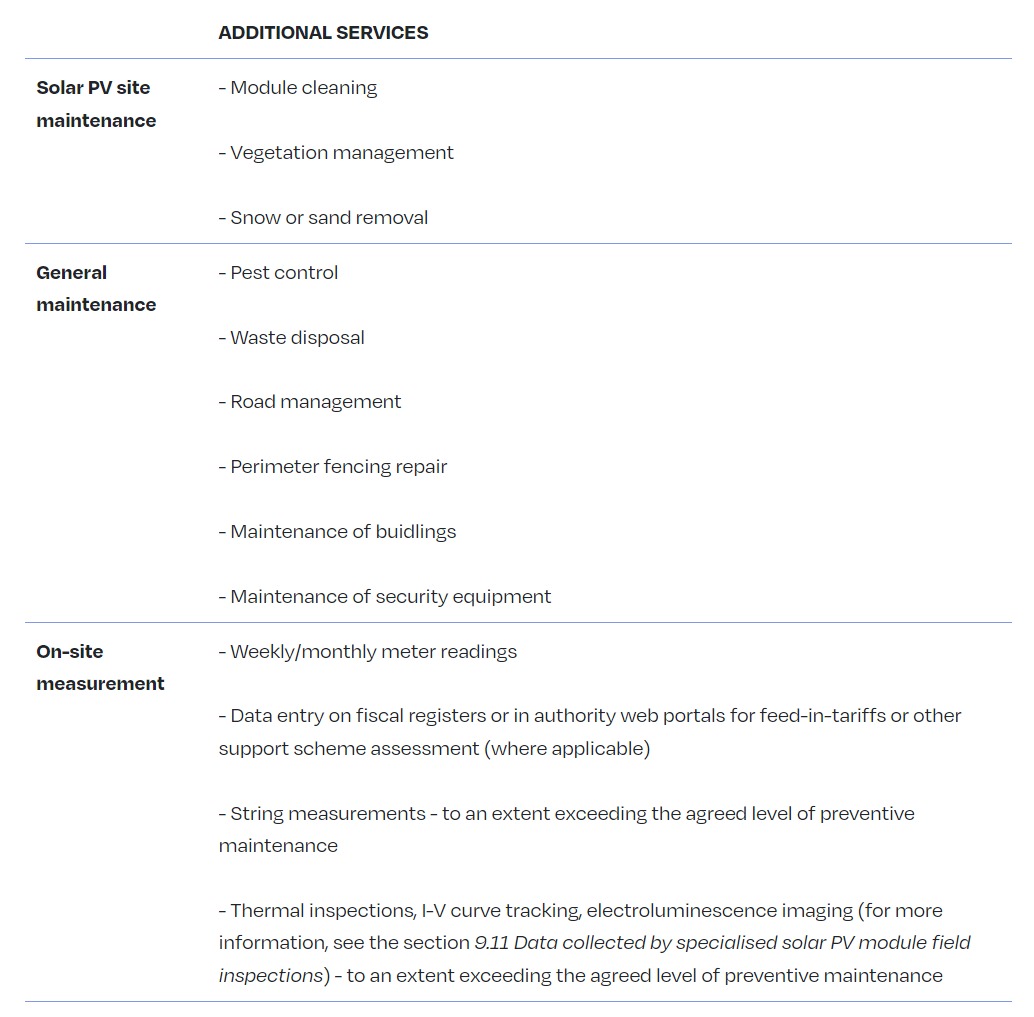

The O&M agreement can foresee services other than those pertaining to electrical and mechanical plant maintenance as per the above sections. Some of these additional services are generally included in the scope of work and the O&M annual fixed fee and some are not.

Additional services not included in the O&M contract scope of work can be requested on demand and can either be priced per service action or based on hourly rates applicable to the level of qualification of staff required to perform the works. These hourly rates usually escalate at the same rate as the O&M Service fee. In some cases, a binding price list for the delivery of some of these additional services can be included in the O&M contract as well.

Module Cleaning

Regular module cleaning is an important part of solar maintenance and the problems associated with soiled modules are often underestimated. Prolonged periods of time between cleans can result in bird droppings etching modules and lichen growth, both of which can be extremely difficult to remove. The intensity and type of soiling depend heavily on the location of the solar PV system (e.g., its proximity to industrial areas, agricultural land, or railway lines).

Module cleaning methods therefore vary from manual, to robotic and mechanical and each have their own advantages and disadvantages. The frequency of cleaning should be decided on a site-by-site basis, and it may be that certain parts of a site will need cleaning more often than other parts of the same site.

When choosing a module cleaning company, Asset Owners and O&M service providers should check the following:

· The suggested method of cleaning is fully in-line with the module manufacturer’s warranty and according to specifications from IEC 61215 (e.g., maximum pressure load)

· The modules should be cleaned with high quality, ultra-pure water, not tap, mains or borehole water. Detergents must be biodegradable and comply with local environmental regulations

· H&S considerations should be made with regard to keeping staff safe on site. This should include some form of H&S accreditation and specific training for solar module cleaning, including working at height, if cleaning roof mounted modules

The table below presents a non-exhaustive list of Additional services.

Some of these items can be considered as a part of Preventive Maintenance. This depends on the agreement between the Asset Owner and the O&M service provider.

From a technological point of view, the usage of aerial inspections is beneficial to efficiently (time and costs) obtain a context awareness needed to perform better planning of site maintenance activities as well as execution of on-site measurements (specifically thermographic inspections).

Advanced aerial thermography

While thermographic inspections have become well established as a tool in preventive and corrective maintenance scheduling, the amount of effort and manual labour required for data gathering in the field has posed financial and operational challenges for their widespread use.

Using thermographic cameras mounted on drones (Remotely Piloted Aircrafts, RPAs or Unmanned Aerial Vehicles, UAVs) or purpose-modified piloted aircraft, instead of handheld devices, the operator flies over the solar PV modules to capture thermographic images or videos. This data is then analysed to create inspection reports which can be used to form the basis of Preventive and Corrective Maintenance tasks. If deployed properly, aerial thermography can provide several operational and financial advantages. It also reduces H&S risks involved in manual inspections, such as prolonged field exposure in dangerous working environments, and the hazards involved in moving around the site, particularly on rooftop installations. Aerial inspections can also pinpoint anomalies to precise locations, thus focusing and reducing the time required for repair work.

Please refer to the Aerial Thermography Checklist of the Solar Best Practices Mark for a synthesis of the most important best practices and recommendation with respect to aerial thermography.[2]

Data acquisition

In this stage a flyover is performed where raw infrared (IR) thermographic images and visual photos or videos are recorded. Depending on the solution, additional geolocation services and 3D modelling of the entire plant may be offered. Some other solutions provide additional sensors to record weather variables (usually irradiance and ambient temperature) during the flyover. The drone is typically pre-programmed with a flight path designed to cover the entirety of the solar PV asset being inspected. The pre-programmed flight path allows for precise and repeatable flights to be performed, increases the accuracy of results, and ensures that the same parameters are used during each subsequent aerial inspection.

With the advent of aerial inspections, resources required for data collection can be significantly reduced. For instance, a 12MWp solar PV power plant can be inspected in a single day. Aerial IR thermography must always be conducted following a set of minimum technical requirements (described in IEC TS 62446-3:2017). Otherwise, it is of little value for effective plant maintenance. In that context, high-quality IR images captured by an aerial platform and their proper post-processing allow for a detailed solar PV module failure analysis that could trigger conclusive maintenance decisions. Furthermore, field interventions can be optimised, and solar PV power plant underperformance can be better understood and addressed (e.g., faulty modules that need to be replaced can be identified with precision and high-quality IR images can be used as proof in warranty claims or in correlation with solar PV monitoring data). Additionally, since images are taken from the air, the data yields a helpful overview for checking whether plant layout, its electrical/physical configuration and other documents are correct.

As with any form of thermography, the inspection method and its diagnostic efficiency are significantly limited by and dependent on meteorological conditions. For the inspection data to be of value, a minimum radiation of 600 W/m2 is required. For drone inspections, to control the RPA safely wind speeds should not exceed 28 km/h (this is dependent on the type of RPA used).

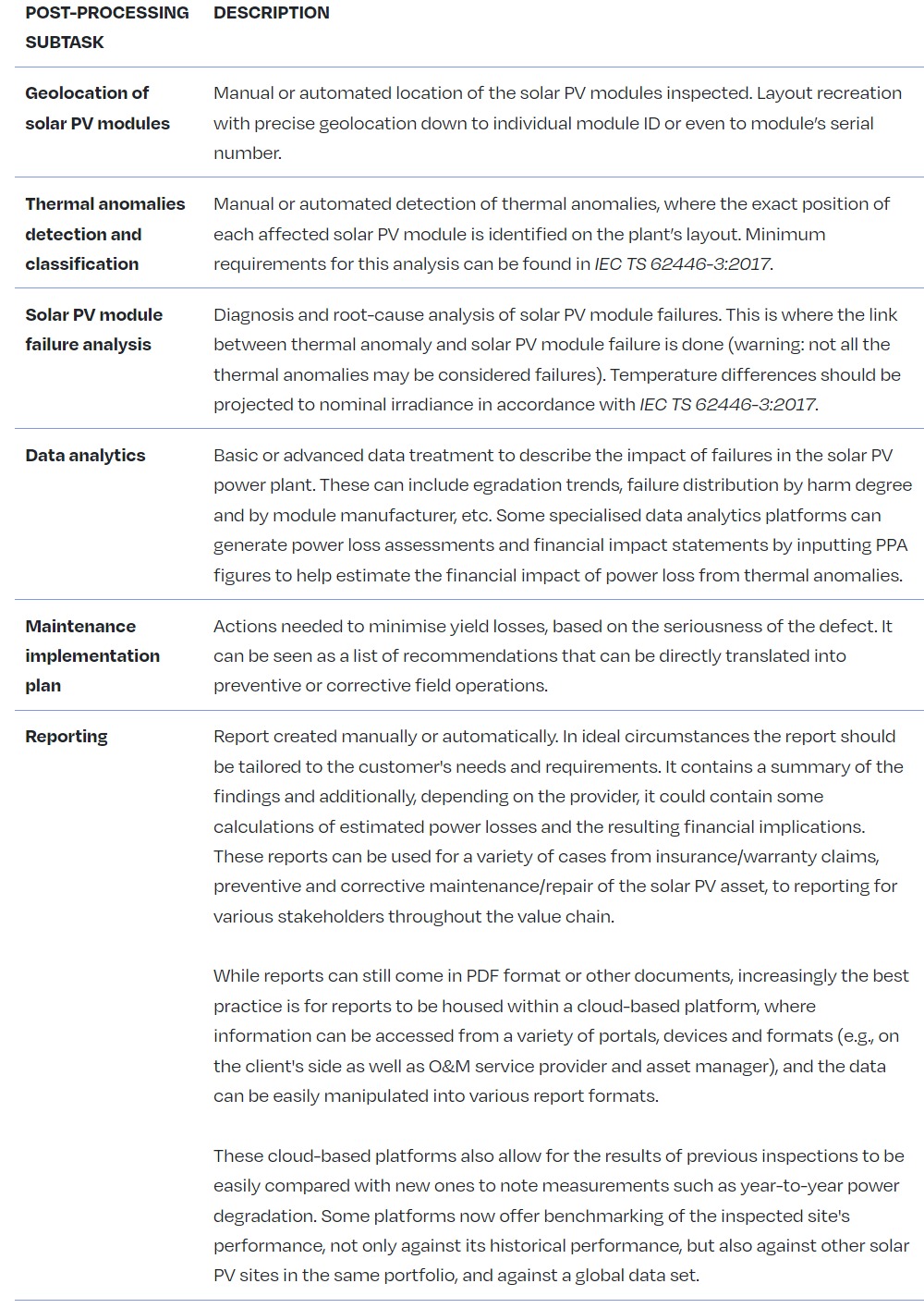

Post-processing

The post-processing activities consist of all the data processing and analysis techniques used to produce the final report and all the related deliverables. These activities can be done manually or automatically with specialised software.

The activities comprised in this stage are described as a series of subtasks in the following table.

There are many companies offering high-quality industrial aerial flights in the market. These are typically referred to as Drone Service Providers (DSPs). While there are companies using drones in a variety of situations (IR inspections of solar PV power plants, wind turbines, oil ducts, offshore oil extraction platforms, and infrastructure etc.), DSPs are emerging that focus solely on the solar solar PV segment. Therefore, this data acquisition stage is an activity that could be easily outsourced by O&M service providers, mitigating the risks related to technology obsolescence and avoiding the costs and complexities of regular drone maintenance. This is particularly beneficial given the rapid rate of development and innovation in the drone technology space. Selecting a DSP with specialisation in solar solar PV inspections gives O&M service providers the additional advantage of relevant expertise and experience, which can equip them with superior insights from the data captured.

There are some companies which utilise specially modified piloted aircraft, flying at a higher altitude, in lieu of drones for inspections of large sites and portfolios. These aircraft are able to cover ground quicker than drones (up to 150MW/hr) while maintaining high resolution due to the higher quality of cameras which can be used. However, these systems are prohibitively expensive for individual sites due to the large mobilisation costs.

Most companies today still rely on manual data processing, which represents a major drawback for large portfolios as human-error (and user-dependence) drives down the accuracy and “consistency” of thermal imaging assessments. This means that companies with automated solutions have a huge advantage in this regard. The advent of AI and machine learning algorithms built into automated data processing solutions also provides customers with significantly greater processing speed and inspection accuracy, and analyses that improve over time.

Aerial inspections and their associated post-processing activities are evolving very rapidly, and the adoption of such new technologies is of significant strategic importance in today’s highly competitive O&M market. As the playing field moves towards a post-subsidy era, such additional services as advanced aerial thermography that can save O&M service providers time and money, seeing them become a standard practice out of necessity.

Pilots

Any aerial thermography or other solar PV module and plant monitoring application involving drones or piloted aircrafts must be carried out by a licensed and insured operator and in accordance with all local and EU-level civil aviation regulations. Before any such operations can take place, each flight must be thoroughly planned from a logistics, regulatory and safety perspective, and a comprehensive on-site risk assessment conducted, with findings recorded in a flight log. In addition to the collected inspection data, each flight should also be fully recorded in terms of date, time, wind speed and direction and battery levels.

Vegetation Management

Vegetation management can represent a significant portion of the operations costs of a solar PV system. Some key items to consider in vegetation management:

- Damage Reduction: Vegetation management can reduce direct mechanical damage caused by vegetation - especially woody vegetation - growing into modules and structures. Damage can also be caused by direct shading causing hot-spot formation on modules, potentially leading to long-term module damage

- Performance Enhancement: Vegetation can cause module shading, which leads to degraded module performance. This effect is disproportionate to the amount of shading, so a small amount of shading can cause a significant amount of power loss

- Erosion Control: Vegetation is critical for soil stabilisation and avoidance of erosion damage on sites. Uncontrolled erosion can cause significant structural damage on a project over time

- Carbon Sequestration: Continuous vegetation management can assist in increasing soil carbon sequestration, especially with the use of grazing animals, who are able to fertilize the soil while enhancing soil carbon capture

- Biodiversity Enhancement: The use of natural pollinators and native vegetation can enhance local biodiversity. This can improve community engagement, lead to reduced vegetation management costs, and in some cases add revenue streams to a project

- Community engagement and social license to operate: Vegetation management can be one of the most visible maintenance activities for local communities and can affect aesthetics, noise pollution, erosion, runoff, and chemical contamination concerns. Vegetation management done well can enhance relations with the community and local councils and improve the social license to operate. Done poorly, vegetation management can cause conflict with local communities and planning councils and can lead to potential legal concerns

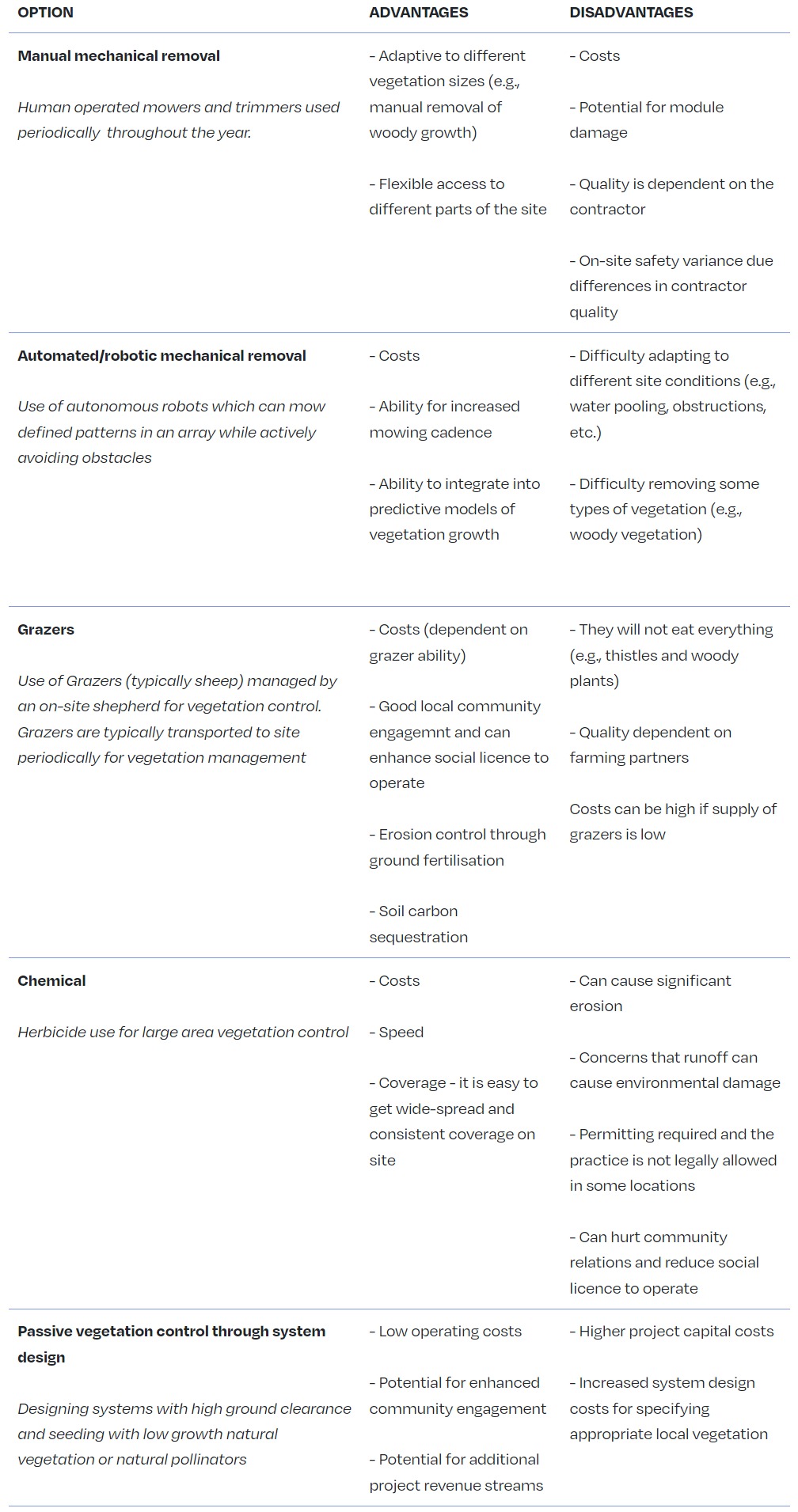

Some options for vegetation management are outlined in the table below:

Data and Monitoring Requirements

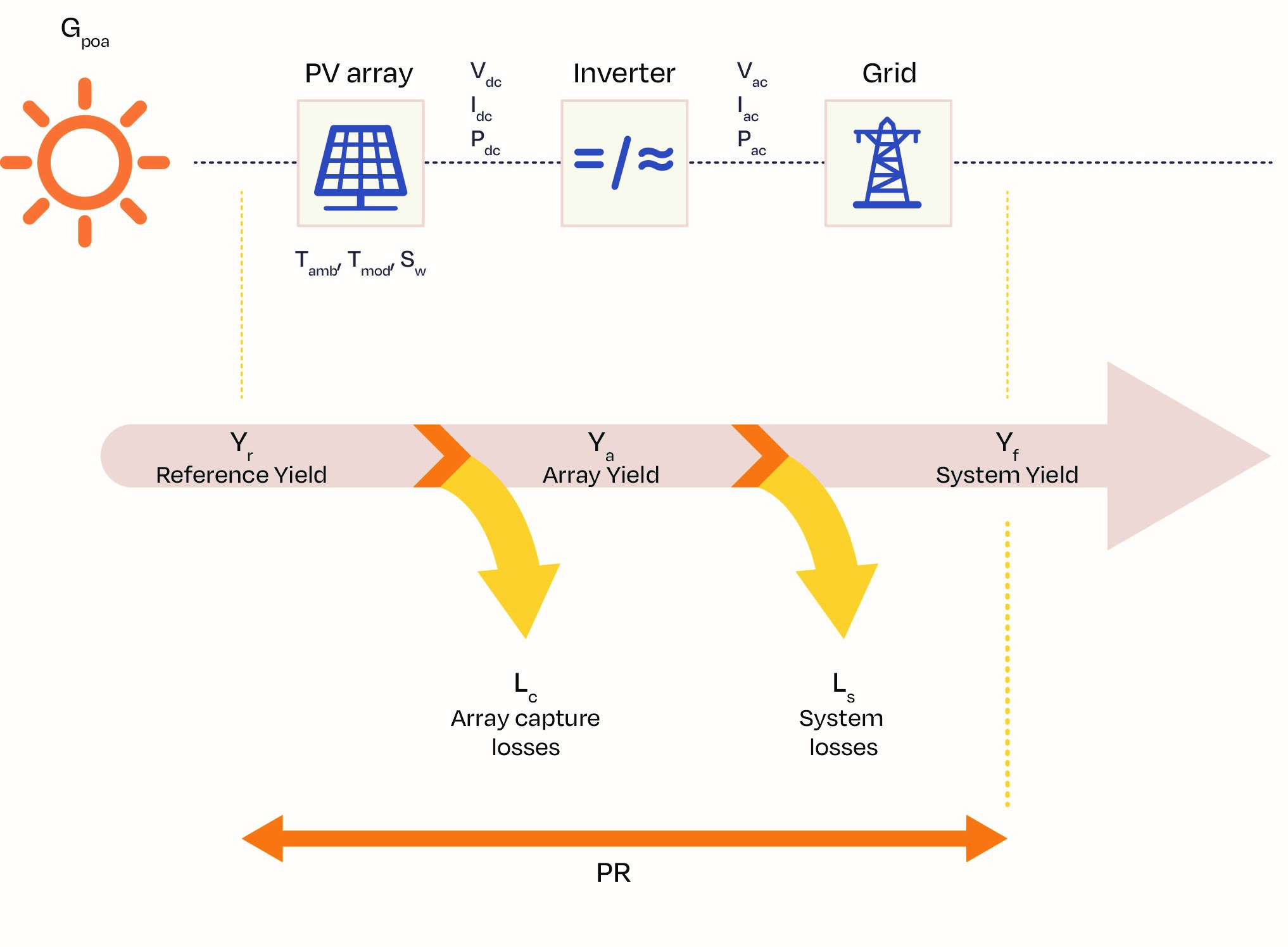

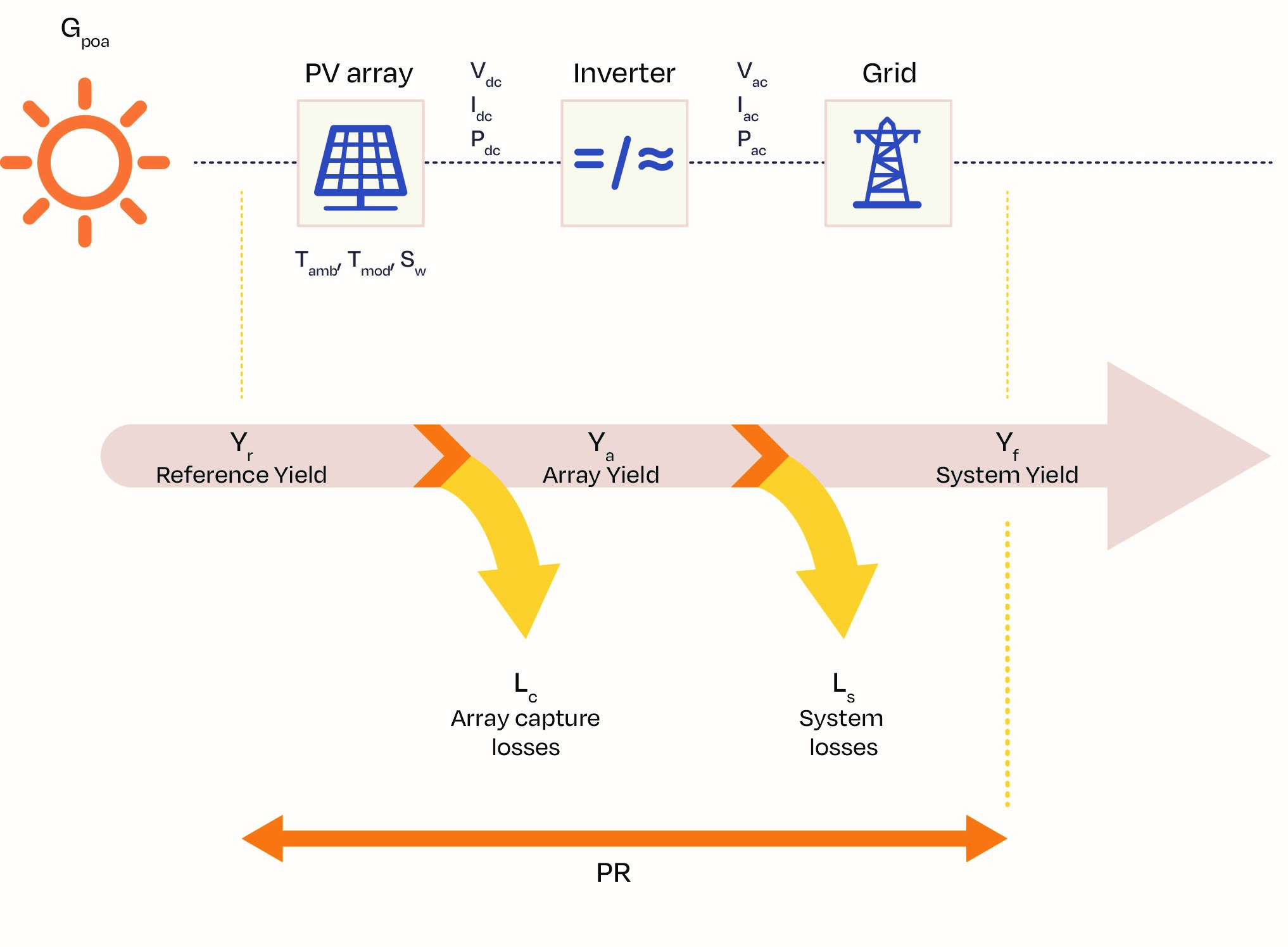

In general, monitoring systems should allow follow-up on the energy flows within a solar PV system. In principle, it reports on the parameters that determine the energy conversion chain. These parameters, along with the most important energy measures in terms of yields and losses, are illustrated in Figure 6. These yields and losses are always normalised to installed solar PV power at standard test conditions in kilowatt-peak (kWp) for ease of performance comparison.

All components and different aspects of technical data management and monitoring platforms are described in the following paragraphs. Reference should also be made to the Monitoring Checklist of the Solar Best Practices Mark for a synthesis of the most important best practices and recommendation with respect to these points.[1]

Data loggers

The main purposes of a datalogger are:

· Collecting data of relevant components (inverters, meteorological data, energy meter, string combiners, status signals) with every device registered separately

· Basic alarm functionality (e.g., Field Communication issues, time critical events like AC Off)

· Providing a temporary data backup (in case of missing internet connection)

· Supporting the technicians during commissioning (e.g., checking whether all inverters work and feed-in)

In addition to this, some dataloggers can also provide the following functions:

· Power Plant Controller (Monitoring & Control should be managed by one instance to avoid communication issues regarding concurrent access). The Power Plant Controller can be integrated in the datalogger or can be a separate device using the communication channel of the datalogger or even a separate one with preferential bandwidth

· Solar Energy Trading Interface (control the active power by a third-party instance like energy trader)

As best practice, dataloggers should be selected following a list of criterion by the operating party as listed below. For example, an EPC service provider will choose and install the data logger used to monitor the site. This datalogger should be selected:

· for its compatibility with the inverters and auxiliary equipment present on site. Preference for inverter-agnostic dataloggers

· for any command functionality that may be needed (this is site type and country specific)

· for its connectivity strength to the internet

· for its robustness (longevity of life and durability for the environmental conditions it will be kept in)

· for its cyber security measures (and those of the cloud server to which it is connected), namely the possibility to set up a VPN tunnel at least

· for its capability to store data during internet communication outages

The recording interval (also called granularity) of the datalogging should range from 1 minute to 15 minutes. Within one monitoring environment granularity should be uniform for all the different data collected.

As a minimum requirement, data loggers should store at least one month of data. Historical data should be backed up constantly by sending it to external servers and, after every communication failure, the data logger should automatically send all pending information. Moreover, data transmission should be secure and encrypted. There should also be a logbook to track configuration changes (especially relevant when acting as Power Plant Controller).

As a best practice, the data logger should store a minimum of three months of data locally and a full data backup in the cloud. Moreover, the operation of the data logger itself should be monitored. This should be done remotely and from an independent server, delivering information on the data loggers’ operating status at Operating System (OS) and hardware level. It should also provide alerts to the Operations room in case of failures and communication loss.

Best practice is to have dataloggers and routers constantly monitored by a watchdog device on-site. In case of no response to the control unit, the power supply will be interrupted by the watchdog unit, performing a hard reset on the stopped equipment. In cases where it is not possible to have an external watchdog it can be useful to have an automatic reboot function.

The entire monitoring installation should be protected by an uninterruptable power supply (UPS). This includes data loggers, network switches, internet modems/routers, measurement devices and signal converters.

Data Quality & Curation

The main purpose of the monitoring system is to collect data from all the relevant components (energy meters, meteorological sensors, inverters, string combiner boxes, etc.) which are typically installed across the field and connected to the plant SCADA through the local network by using various technologies (serial links, cable, fiber, wireless, etc.). Moreover, renewable plants, and solar plants, are often situated in remote environments, and sometimes in harsh places. As such, equipment and systems are subject to difficult conditions and are often subject to data quality issues.

The data quality issues that equipment may face may be categorised as follow:

· False negative values

· Outliers

· Spikes

· Data gaps

· Junk values

These data quality issues can provoke situations that vary extremely depending on the plant, type of measurement, or systems in place. As such, it is very difficult to implement an overall and systematic data quality strategy for renewable Asset Owners as each case is unique.

The data quality issues mentioned above are obvious and may impact many KPIs which are calculated on this basis. More challenging to identify, are slight and progressive data deviations overtime.

Biased KPIs lead to unnecessary operations costs (unrequired on-site intervention) and performances losses, as defects may remain undetected.

As a best practice, the monitoring solution and system should be capable of filtering these values in the most automated and personalised way to cater for each specific case.

Most effective techniques for data validation are based on the analysis of data over relatively long timespans (i.e., daily data validation), with a granularity between 1 and 15 minutes.

Monitoring (web) portal

The main purposes of the monitoring portal are:

· Reading any type of raw data coming from any type of data logger or other solar PV platforms with no preference on brands or models

· Creating a long-term archive for all raw data provided by the asset

· Modelling each solar PV asset using all available information regarding the actual set up and devices (type of devices, installation/replacement date, modules-string-inverter system layout, modules inclination, orientation, type of installation etc.)

· Visualising aggregated data in the highest possible granularity (1 to 15 min is a best practice for most of the indicators)

· Visualising data in standard and specific diagrams

· Computing and visualising dashboards and views of KPIs. Indicators computational inputs might be selectable by the user

· Validating data quality (e.g., through calculation of data availability)

· Detecting malfunctions as well as long term degradations with customisable alarms

· Handling alerts from field devices like dataloggers or inverters

· Calculating typical KPIs (such as PR and Availability) with the possibility to adapt parameters

· Providing consistent and easy to use aggregated KPIs for customisable reports for single plants and portfolios

· Making data available via a standardised interface for use in other systems

The monitoring portal should fulfil the following minimum requirements:

· Accessibility level of at least 99% across the year

· Interface and/or apps dedicated to use cases (on-site service, investor etc)

· Customisable user Access Level

· Graphs of irradiation, energy production, performance, and yield

· Downloadable tables with all the registered figures

· Alarms register

As best practice, the following features will also be included in the Monitoring Portal:

· Configurable User Interface to adjust the views depending on the target group (e.g., O&M service provider, EPC service provider, Investor, Asset Manager)

· User configurable alarms

· User configurable reports

· Ticket system to handle alarm messages

· Plant specific KPIs

· Integrate Third Party Data (e.g., solar power forecast, meteorological data, satellite data for irradiance)

· Granularity of data should be adaptable for downloads of figures and tables

The above lists are not exhaustive. For a comprehensive overview of recommended functionalities, refer to the Monitoring Checklist of the Solar Best Practices Mark.[3]

Data format

The data format of the recorded data files must respect standards such as IEC 61724 and must be clearly documented. Data loggers should collect all inverter alarms in accordance with original manufacturer’s format so that all available information is obtained.

Configuration

The configuration of the monitoring systems and data loggers needs to reflect the actual layout of plant details (hardware brand, model, installation details such as orientation, wiring losses, set up date, etc.) to better perform expected performances simulations and obtain consistent insight about a plant’s actual status. If this has not been done during the plant’s construction phase, it should be done at the commissioning phase or when a new O&M service provider takes over (recommissioning of the monitoring system).

During commissioning, each single piece equipment monitored should be checked to make sure it is properly labelled in the Monitoring System. This can be done by temporarily covering insolation sensors or switching off others such as string boxes or inverters.

It is best practice to have a Monitoring System capable of reading and recording all IDs from all sensors and equipment it monitors. This will reduce the possibility of mislabelling elements and improve the tracing of equipment and sensor replacement during the life of the facility. Some Monitoring Systems have even an auto-configuration feature (plug-and-play) that reduces start-up time and potential mistakes. This it is done by automatically capturing device IDs and configuration information. This also allows for automatic detection of inverter or sensor replacement.

Interoperability

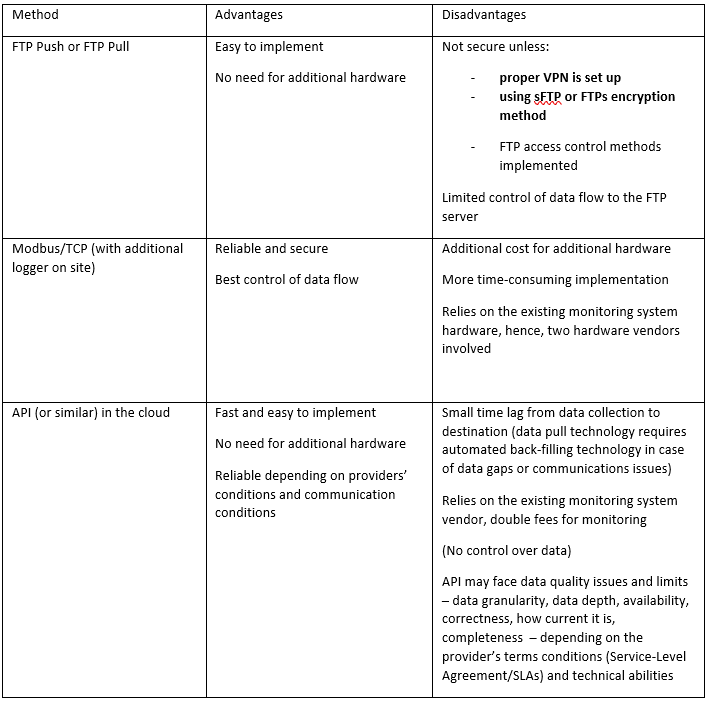

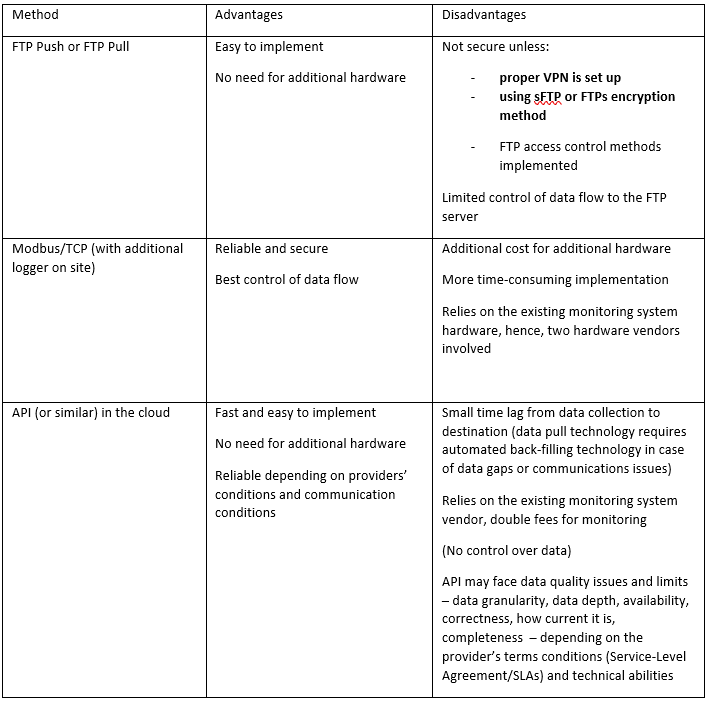

As a best practice, the system should ensure open data accessibility (both for sending and receiving data bilaterally) to enable easy transition and communication between monitoring platforms. Table 6 shows some examples of data integration options. Due to the lack of unifying standards, every Monitoring System provider has their own method of storing and retrieving data. The best systems can retrieve data by using open interfaces such as RESTful, providing interoperability between different systems.

Another important aspect of interoperability is the ability to aggregate data from different platforms that serve a range of areas in the solar PV business, such as administration, accountancy, planning & on-site intervention, and stock management applications. This way, information can be exploited by the central monitoring platform without affecting the external applications. For example, an O&M service provider works with several types of ticketing systems for different clients. The monitoring platform should be able to collect data from all of them. Likewise, information about tickets managed from the central monitoring system should be automatically transferable to the dedicated ticketing application.

Internet connection and Local Area Network

The O&M service provider should make sure to provide the best possible network connectivity. As a minimum requirement, the bandwidth needs to be adequate enough to transfer data in a regular way.

Whenever a fibre connection is available within the solar PV-site area, this should be used to connect to the internet, with industrial routers considered as standard. Where a fibre connection is unavailable, 4G or Wi-Fi communication is preferred. Satellite connection is the least preferred communication type. An additional back-up system is best practice. Any subscription should allow for the data quantity required and should foresee the amount (e.g., Closed-Circuit Television (CCTV) or not)granularity of the data.

For solar PV power plants larger than 1MW it is advised to have a WAN connection and as an alternative to an industrial router, that allows for mobile or satellite communication back-up in case the WAN connection fails. A system with a reset capability in case of loss of internet connection is recommended. A direct connection to a monitoring server with an SLA guarantees continuous data access. If data passes via alternative monitoring servers without an SLA, (e.g., monitoring portal of the inverter manufacturer), the SLA can no longer be guaranteed. The automatic firmware updates of the data logger should be disabled. Firmware updates are subject to a change management procedure with the monitoring service.

All communication cables must be shielded. Physical distances between (DC or AC) power cables and communication cables should be ensured, and communication cables should be shielded from direct sunlight. Furthermore, cables with different polarities must be clearly distinguishable (label or colour) for avoiding polarity connection errors.

Pros and cons of different types of monitoring connections:

Data ownership and privacy

The data from the monitoring system and data loggers, even if hosted in the cloud, should always be owned by and accessible to the Asset Owner (or SPV). Stakeholders such as the O&M service provider and the Asset Manager need the data to perform their duties and should be granted access. In addition to this, auditors working in the due diligence phases of a project should also have access. It is important to have at least two access levels (read-only, full access).

The monitoring system hardware can be provided by the O&M service provider or a third-party monitoring service provider (but the monitoring system hardware remains the property of the Asset Owner as part of the installation):

· If the O&M service provider is the monitoring service provider, they have full responsibility for protecting and maintaining the data, and ensuring the proper functioning of the monitoring system

· Where there is a third-party monitoring service provider, responsibility for protecting and maintaining the data resides with them. The O&M service provider should endeavours to make sure performance monitoring is correct and takes the best practices mentioned in the previous paragraphs into consideration. The O&M service provider’s ability to properly maintain and use the monitoring system should be evaluated. If necessary, the O&M service provider should be appropriately trained to use the monitoring system. Data use by third-party monitoring providers should be extremely limited, i.e., for correcting bugs and developing additional functions to their systems.

Cybersecurity

As solar PV power plants have inverters and power plant controllers (and monitoring systems) that are connected to the internet to enable surveillance and remote instructions by operators, there are significant cybersecurity risks.

Cybersecurity comprises technologies, processes and controls that are designed to protect systems, networks, and data from cyber-attacks. Effective cyber security reduces the risk of cyber-attacks and protects organisations and individuals from the unauthorised exploitation of systems, networks, and technologies.[4]

Cybersecurity is a vast area and multiple measures are possible. The following hints may help as a starting point:

· Keep it simple: If possible, reduce the type of network devices to a minimum

· As a recommendation, traffic of the network devices may be monitored to detect abnormally high use of bandwidth

· Secure physical access to the network devices and implement a secure password policy. Avoid the use of standard passwords and change all factory setting passwords

· Control access from Internet via strict firewall rules:

- Port forwarding should not be used because this is a big security gap. Only router ports that are necessary should be opened

- Reduce remote access to the necessary use cases

- The use of VPNs (Virtual Private Networks – a secure connection built up from the inside of the private network) is necessary

- VPN access to the site from outside is a minimum requirement

- A VPN server or VPN service which works without requiring a public IP on-site is preferred

- Each solar PV power plant should have different passwords

- Keep your documentation up to date to be sure that no device has been forgotten

- Use different roles to the extent possible (e.g., read only user, administration access)

- Use professional (industrial grade) hardware; only this hardware provides the security and administration functions your plant needs to be secure

· Implement vulnerability management (i.e., identifying and fixing or mitigating vulnerabilities, especially in software and firmware):

- Improve insecure software configurations

- The firmware and software of devices should be kept up to date

- Use anti-virus software if possible and keep it up to date

- Avoid wireless access if it is not necessary

- Audit your network with the help of external experts (penetration tests)

· Keep your company safe:

- Do not store passwords in plain text format, use password manager (e.g., 1Password, Keepass, etc.)

- Train your employees on IT security awareness

- Do not share access from all plants to all employees. Give access only to those who need it. This way damage can be limited if an individual employee is hacked

- Management of leaving and moving employees; change passwords of plants which are overseen by an employee who has left the company or moved to another department

It is therefore best practice that installations undertake a cyber security analysis, starting from a risk assessment (including analysis at the level of the system architecture) and implement a cybersecurity management system (CSMS) that incorporates a plan-do-check-act cycle. The CSMS should start from a cybersecurity policy, and definition of formal cybersecurity roles and responsibilities, and proceed to map this onto the system architecture in terms of detailed countermeasures applied at identified points (e.g., via analysis of the system in terms of zones and conduits). These will include the use of technical countermeasures such as firewalls, encrypted interfaces, authorisation and access controls, and audit/detection tools. They will also include physical and procedural controls, for example, to restrict access to system components and to maintain awareness of new vulnerabilities affecting the system components.

As a minimum requirement, data loggers should not be accessible directly from the internet or should at least be protected via a firewall. Secure and restricted connection to data servers is also important.

The manufacturer of the datalogger and the monitoring platform should provide information on penetration tests for their servers, any command protocol activation channels, and the results of security audits for their products. Command functions should be sent using a secure VPN connection to the control device (best practice). Double authentication would be an even more secure option.

For further information, beyond the scope of this document, please look at the EU Cybersecurity Act (EC, 2019) and the European Parliament’s study “Cyber Security Strategy for the Energy Sector” (EP, 2016).

Types of data collected through the monitoring system

Irradiance measurements

Irradiance Sensors

Solar irradiance in the plane of the solar PV array (POA) is measured on-site by at least one irradiance Class A quality measurement device and ISO 9060:2018 (ISO 9060 2018). The higher the quality of the pyranometer, the lower the uncertainty will be. Best practice is to apply at least two pyranometers in the plane of the solar PV array. In case of different array orientations within the plant, at least one pyranometer is required for each orientation. It should be ensured that the pyranometers are properly assigned to the different arrays for the calculation of PR and Expected Yield.

Class A Pyranometers are preferred over silicon reference cells because they allow a direct comparison between the measured performance of the solar PV power plant and the performance figures estimated in the energy yield assessment. For plants in Central and Western Europe, measuring irradiance with silicon cells yields approximately 2 to 4% higher long-term PR than with a thermopile pyranometer (N. Reich et al. 2012).

Irradiance sensors must be placed in the least shaded location. They must be mounted and wired in accordance with manufacturers’ guidelines. Preventive Maintenance and calibration of the sensors must follow the manufacturers’ guidelines.

The irradiance should be recorded with a granularity of up to 15 minutes (minimum requirement).

Further information on the categorisation of plant sizes and the use of appropriate measuring technology is provided in IEC 61724-1.

Satellite-based Irradiance Measurements

In addition to irradiance sensors, complementary irradiance data from a high-quality satellite-based data service can be acquired after a certain period to perform comparisons with data from ground-based sensors. This is especially useful in case of data loss or when there is low confidence in the data measured onsite by the Monitoring System and it can be considered as best practice. In particular, high-quality satellite-based data should be used for irradiation sensor data quality assessments. The longer the period considered the lower the error will be for satellite-based irradiation data. For daily irradiation values, the error is relatively high, with root-mean-square error (RMSE) values of 8 to 14% in Western Europe. For monthly and annual values, it decreases below 5 and 3%, respectively, which is in line with an on-site sensor (Richter et al. 2015).

When satellite-based irradiance data is used, hourly granularity or less (15 minutes if possible) is recommended. The data must be retrieved once per day at least.

Module temperature measurements

Module temperature can be measured for performance analysis in KPIs such as the temperature-corrected PR.

The accuracy of the temperature sensor, including signal conditioning and acquisition done by the monitoring system hardware, should be < ±1 °C.

The temperature sensor should be attached to the middle of the backside of the module in the middle of the array table, in the centre of a cell, away from the junction box with appropriate and stable thermally conductive glue (Woyte et al. 2013). The installation should be in accordance with manufacturer guidelines (e.g., respecting cabling instructions towards the data logger).

Varying solar PV module temperature in a plant is mainly due to different wind exposure. Therefore, in large plants more sensors will be required across the site because module temperature should be measured at different representative positions (e.g., for modules in the centre of the plant and for modules at edge locations where temperature variation is expected).

The granularity of module temperature data should be at least 15 minutes to perform a correct PR calculation.

Local meteorological data

It is best practice to measure ambient temperature, wind speed, rain fall and other site relevant meteorological measurement with the installation of a local meteorological station in accordance with the manufacturers’ guidelines. Ambient temperature is measured with a shielded thermometer, such as a PT100. The shield protects the sensor from radiative heat transfer. Wind speed is measured with an anemometer, at 10m above ground level.

Wind and ambient temperature data are normally not required for calculating PR unless this is a contractual requirement/agreement (e.g., according to specific recommendations such as those from the National Renewable Energy Laboratory in the USA). However, they are required when the solar PV power plant is modelled in operation or retrospectively.

Additionally, whenever the module temperature measurements are not available or not suitable, wind speed and ambient temperature coupled with installation specifications can be used to retrieve a good estimation of module temperature. In this case, 15 minutes granularity of measurement is still the best practice.

For plants larger than 10 MWp, having automated collection of hourly meteorological data (ambient temperature, wind speed, snow coverage, rainfall) from independent sources is recommended. The reason for this is that on-site meteorological stations are subject to local phenomena and installation-specific results. Data from an independent weather-station is less subject to this, while being also more stable and robust with respect to long-term drift. They can therefore be used to evaluate the quality, and eventually replace, the on-site measurement.

Therefore, for both performance assessment and detailed analysis purposes, automated, local meteorological data is recommended. However, for performance assessment the most important measurement remains the in-plane irradiation.

Solar resource data derived from satellite image processing is available from several services at a nominal per-site and per time-segment (such as one week) fee. The measurement error in satellite data might be greater than that of an on-site instrument but is often more reliable than a mis-aligned, inadequate or dirty on-site pyranometer, and less susceptible to soiling or tampering.

String measurements

Individual string current measurements may be deployed when not supported by the inverters. String level monitoring allows for more precise trouble-shooting procedures than at inverter level. Depending on the module technology used in a plant, strings can be combined (in harnesses) which can help reduce operation costs.

To detect problems quickly and to increase plant uptime, installing string monitoring equipment is recommended. This will constantly measure the current of every string and register those measurements in intervals of up to at 15 minutes. To reduce costs, the current sensor can be used to measure more than one string. However, no more than two strings should be measured in parallel.

Inverter measurements

Inverters have a large set of variables that are constantly measured by their hardware, and that can be registered and investigated from the monitoring system. The data sent from the inverter to the monitoring system should be in cumulative values to allow the monitoring of the overall electricity generation of the inverter, even in case of outages of the monitoring system.

Recommended variables to be monitored are:

- Cumulative Energy generated (kWh)

- Instant Active Power injected (kW)

- Instant Reactive Power injected (kVAr)

- Instant Apparent Power injected (kVA)

- AC Voltage per each phase (V)

- AC Current per each phase (A)

- Power Factor / Cos Phi

- Frequency for each phase (Hz)

- Instant DC Power for each MPPT (kW)

- Instant DC Current for each MPPT (A)

- Instant DC Voltage for each MPPT (V)

- Total instant DC Power for all MPPTs (kW)

- Total instant DC Current for all MPPTs (A)

- Average instant DC Voltage for all MPPTs (V)

- Internal temperature (ºC)

- Conversion components temperature (ºC)

- Inverter failure signals

It should be noted that the precision of inverter-integrated measurements is not always documented by the manufacturers and can be imprecise. For example, energy or AC power measurements taken by inverters may differ substantially from the values recorded by the energy meter. Monitoring systems and reporting should specify and be transparent about the devices used to acquire each measurement.

It is also very useful to have the monitoring system collecting data from all the inverter alarms as they are a valuable source of information for fault detection. Also, low importance alarms or warnings can be used for the organisation of maintenance activities and even setting up Preventive Maintenance actions.

In certain cases, grid connections have limits that must be always respected, such as the maximum AC power that can be injected. For these cases there are two possibilities, one is to set limits using inverter parameters, the second one is to install Power Plant Controller that will change inverter parameters dynamically. In both cases it could be useful to monitor inverter parameters and to program alarms so that the O&M service provider is notified when there is a parameter that has been changed wrongly and does not respect a given limit.

Best practice dictates that the sample size for the measurement of inverter-based variables is 15 minutes at one minute interval. For ad-hoc performance analysis purposes such as allowing the analysis of solar PV array performance, root cause analysis or possible MPP-tracking problems, the input DC voltage and current need to be measured and stored separately.

In general, and as best practice, all common inverter parameters should be logged by the data loggers, since there are a lot of additional important parameters, such as internal temperature, and isolation level, etc. that could be useful for O&M services.

Inverters should be capable of detecting when their conversion components are overheating, to protect themselves under extreme or abnormal operating conditions. Therefore, it is advisable to record the temperature as provided by the inverter so that ventilation performance can be assessed.

Energy meter

One of the most important features of a monitoring system is the automated collection of energy meter data with a granularity of up to 15 minutes. Gathering energy meter data is required for invoicing purposes but it is also the best reference for measuring energy and calculating plant PR and Yield. It is also much more accurate than using inverter data.

Using a high accuracy energy meter to measure energy produced and consumed by the plant is normally required by the Utility. When this is not the case it is a best practice to install a meter with a maximum uncertainty of ± 0.5%, especially for plants > 100 kWp.

To allow data acquisition via the monitoring system, it is recommended to have a meter with two communication bus ports as well as Automatic Meter Reading (AMR) service from the Utility or Meter Operator.

For meters that can store historical data it is a best practice to have a Monitoring System capable of retrieving historical data to avoid any production data loss in case of Monitoring System outages.

Control settings

It is important to monitor all control settings of the plant at inverter- and grid injection-level (if available). Many plants apply control settings for local grid regulation (injection management) or optimisation of the market value of the solar PV generation portfolio (remote control). These settings need to be monitored for contractual reporting reasons and performance assessment.

Alarms

As a minimum requirement, the Monitoring System shall be able to generate the following alarms and, at the user’s discretion, send them by email:

· Loss of communication

· Plant stops

· Inverter stops

· Plant with Low Performance

· Inverter with Low Performance (e.g., due to overheating)

As best practice, the following alarms will also be sent by the monitoring system:

· String without current

· Plant under operation

· Discretion Alarm

· Alarm Aggregation

As a best practice, the following alarms should also be tracked by the O&M service provider. However, these alarms are sent by separate systems:

· Intrusion detection

· Fire alarm detection

The above lists are not exhaustive. For a comprehensive overview of recommended functionalities, refer to the Monitoring Checklist of the Solar Best Practices Mark.[5]

AC circuit / Protection relay

Monitoring the status of MV switch gear and important LV switches through digital inputs is recommended. Whenever possible, it can also be useful to read and register the alarms generated by the protection relay control unit via communication bus.

Data collected by specialised solar PV module field inspections

Not all types of data are collected automatically through the monitoring system. Certain data are collected via on-site measurements and field inspections manually or with aerial inspections.

solar PV modules are engineered to produce electricity for 25-30 years and nowadays are being deployed in ever more and ever larger solar PV power plants. Quality assurance is the cornerstone for long-term reliability and maximising financial and energy returns. This makes tracking down the source of failures once modules have been installed vital. For that reason, field technical inspections, such as infrared (IR) thermography, electroluminescence (EL) imaging and I-V curve tracing, are being put into practice to assess the quality and performance of solar PV modules on-site.

Field inspections like these can be part of contractual Preventive Maintenance tasks or could be offered as additional services, triggered by the O&M service provider in cases where, for example, plant underperformance is not clearly understood just by looking at monitoring data.

Infrared thermography (IR)

Infrared (IR) thermographic data provides clear and concise indications about the status of solar PV modules and arrays and are used in both predictive and corrective maintenance.

Depending on its temperature, every object (e.g., a solar PV module) emits varying intensities of thermal radiation. As explained by Max Planck’s theories, this radiation measurement can be exploited for the determination of the actual temperature of objects. Thermal radiation – invisible to the human eye – can be measured using an infrared camera and is presented in the form of a thermal image. If abnormalities in solar PV modules occur, this typically leads to higher electrical resistance and thus a change in temperature of the affected module or cell. Based on the visual form and quantifiable temperature differences over the thermal image of a solar PV module, abnormalities such as hotspots, inactive substrings or inactive modules can be identified.

For thermographic data to be usable, a number of minimum requirements have to be met. Irradiance shall equal a minimum of 600 W/m2 and shall be continuously measured on-site, ideally orthogonally to the module surface. Infrared cameras need to possess a thermal resolution of at least 640 x 512 pixels and a thermal sensitivity of at least 0.04 K. Measurements shall be taken at a distance which ensures that the resolution of the infrared image equals 5 x 5 pixels per solar PV cell. Further requirements are to be found in IEC TS 62446-3 Part 3: Photovoltaic modules and plants – outdoor infrared thermography.

IR thermographic data can be captured with specialised IR thermographic cameras mounted either on manual hand-held devices or on drones. There are significant advantages in time and cost savings, speed and accuracy of data analysis and reporting, and worker health and safety that come with drone-enabled IR thermography as opposed to traditional manual inspection methods. The larger-scale the solar PV asset, the greater the advantages become.

Besides solar PV modules, IR thermography can also be used to inspect other important electrical components of a solar PV power plant, such as cables, contacts, fuses, switches, inverters, and batteries. For more information, see IEC TS 62446-3 Part 3: Photovoltaic modules and plants – outdoor infrared thermography and IEA-PVPS T13-10:2018 report: review on infrared and Electroluminescence imaging for solar PV Field applications.

The use of IR thermography alone is sometimes not enough to reach a conclusive diagnosis on the cause and the impact of certain solar PV module failures. Therefore, it is usually combined with the following complementary field tests.

I-V curve tracing on-site

Measurements of the I-V curve characteristic determine the power, short-circuit current, open-circuit voltage and other relevant electric parameters (shunt and series resistance, fill factor) of single solar PV modules or strings. The shape of the curve provides valuable information for identifying failures and it also provides a quantitative calculation of power losses. A typical outdoors I-V curve measurement setup consists of a portable I-V curve tracer. In combination with an irradiance sensor (a reference cell usually) and a thermometer this can be used to measure the solar PV modules electrical behaviour. As on-site ambient conditions differ greatly from those in a standardised lab, the measured results should be translated into STC.

Electroluminescence (EL) imaging on-site

EL images are typically taken of every module when leaving the factory production line and are a very useful baseline for the health of the module before leaving the factory. An EL image will show cell level imperfections and cracks which are invisible to the naked eye. EL imaging can be used on-site to better understand module quality post installation as well as further investigation following the identification of anomalies by thermography.

During the EL testing a material emits light in response to the passage of an electric current. This is applied in order to It is used to check integrity of solar PV modules. Here, a current flows through the solar PV-active material, and as a result, electrons and holes in the semiconductor recombine. In this process the electrons release their energy as light. EL imaging detects the near infrared radiation (NIR), i.e., wavelengths between 0.75 and 1.4 μm. The EL is induced by stimulating single solar PV modules or strings with a DC current supplied by an external portable power source. The NIR emissions then are detected by a silicon charge-coupled device (CCD) camera.

EL is usually done in a dark environment because the amount of NIR emitted by the solar PV modules is low compared to the radiation emitted by the background light and from the sun. This requires that EL imaging conducted on-site has to be done during the night, while covering the solar PV modules with a tent, or in a purpose-built mobile test lab. A typical setup consists of a modified single-lens reflex (SLR) camera, a tripod, a portable DC power supply and extension cables. Additionally, a high pass edge filter at 0.85 μm may be used to reduce interfering light from other sources. The resolution of the camera should be at least high enough so that the fingers of the solar cells in the module can be clearly identified. The noise of the camera output must be as low as possible (lowest ISO number possible) and the camera should be as steady as possible in order to avoid blurry images. Exposure times of 15 seconds are common.

High volume approaches to EL testing such as using drones are being offered by some niche service providers.

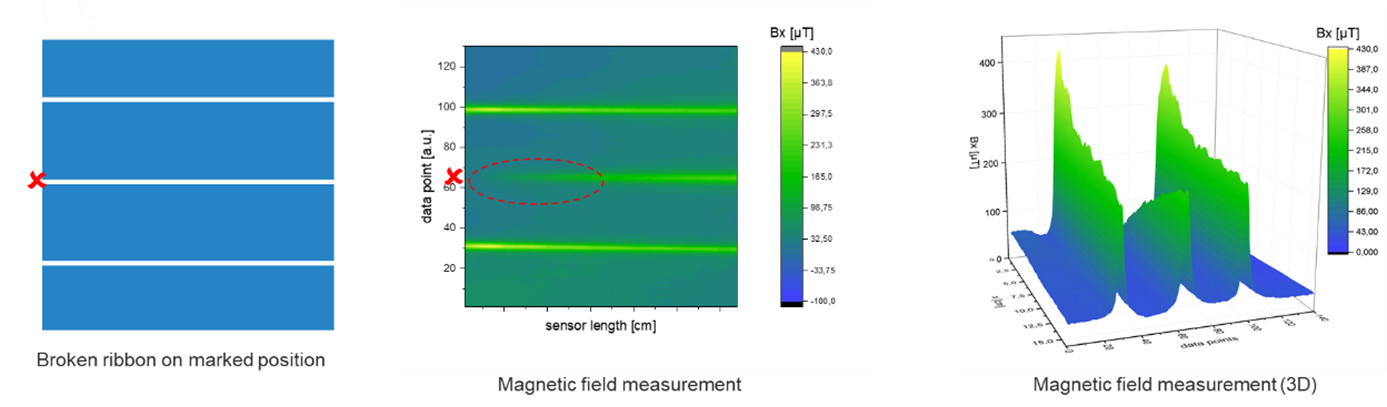

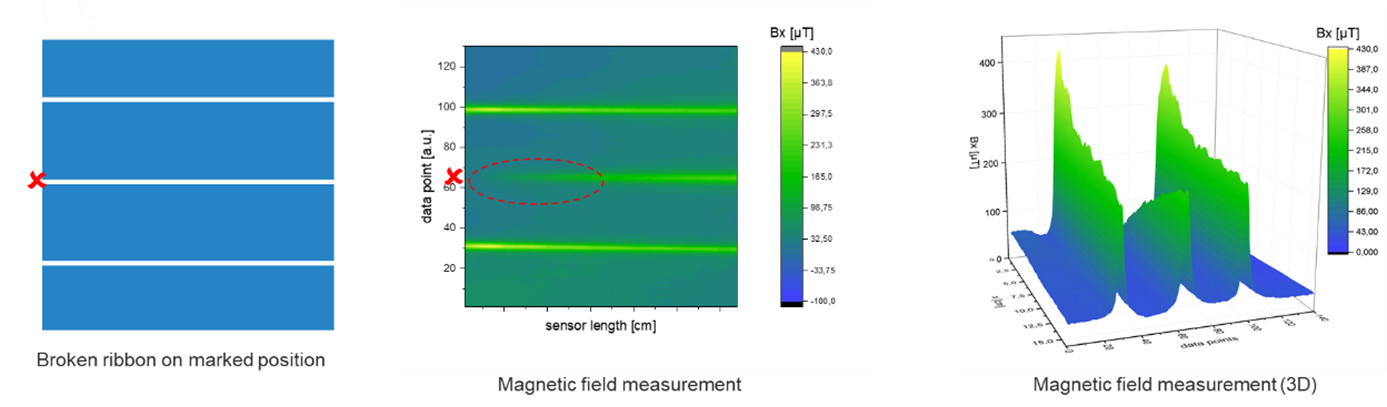

Magnetic Field Imaging (MFI)

Magnetic field imaging (MFI) is a new and innovative method for quantitatively analysing flowing electric currents non-destructively, and without contact.

The underlying physics are very simple: every electric current generates a magnetic field. A magnetic field sensor creates an image of this by being moved over the current-carrying component. Strength and direction of the electric current can be inferred from this.

Current-carrying components such as solar cells, modules or batteries have a characteristic current distribution. If components have defects that influence the electrical current distribution significantly, the resulting magnetic field also changes. These changes can be detected by MFI and thus traced back to the defects.

The fields of application are manifold. In solar PV, defects relevant for the operation of solar modules can be detected reliably (Lauch et al, 2018; Patzold et al, 2019). These are, for example, broken connectors or ribbons (see Figure 29), missing solder joints or defective bypass diodes in the junction boxes of the modules.

The advantages of the measurement technique that it is non-destructive, fast, and quantitative (the measurement signal is proportional to the underlying electric current). A disadvantage of using magnetic fields is that the distance to the sample must be in the millimeter range to produce high quality imaging results. The measurement cannot resolve microscopic structures (< 100 µm), yet.

Soiling measurements

The operational efficiency of modules is affected by soiling accumulation. Soiling limits the effective irradiance and, therefore, the output of the solar PV module. Measuring soiling I recommended as it can help optimise cleaning schedules and thus revenues. Several methodologies exist for soiling monitoring, the most basic being human inspections. A widely used soiling measurement method is using ground-based soiling reference modules consisting of a module that remains soiled, a cleaned reference cell, an automatic washing station and measurement electronics. There are several variations using different principles to measure the effect of soiling. Digital solutions for soiling monitoring that are currently under development include the analysis of satellite imagery with remote sensing techniques, machine intelligence algorithms and statistical methods. Possible soiling analyses include taking a swab of the soil to an analytical laboratory to determine its nature (diesel soot; pollen; organic soil; inorganic dust) and the appropriate cleaning solution.

Key Performance Indicators

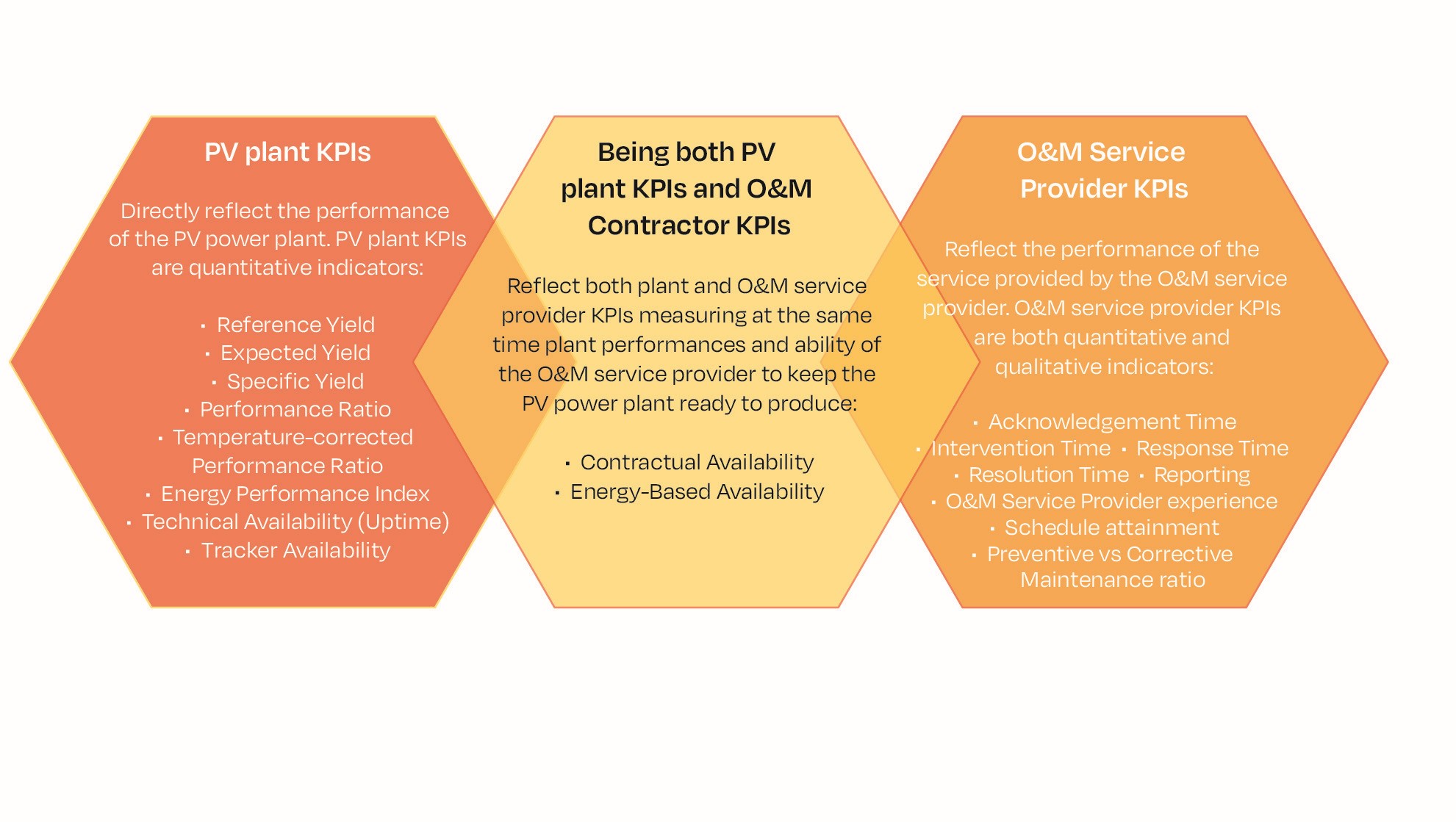

The Key Performance Indicators (KPIs) provide the Asset Owner with a quick reference on the performance of the solar PV power plant. The KPIs in this section are divided into the following categories:

· Solar PV power plant KPIs, which directly reflect the performance of a solar PV power plant. They are quantitative indicators.

· O&M service provider KPIs, which reflect the performance of the service provided by the O&M service provider. O&M service provider KPIs are both quantitative and qualitative indicators.

· Solar PV power plant/O&M service provider KPIs, which reflect solar PV power plant performance and O&M service quality at the same time.

The O&M service provider (or the Technical Asset Manager) is generally responsible for the calculation of the KPIs and reporting to the Asset Owner.

It is important to underline that the O&M service provider is not responsible for providing contractual guarantees for all the KPIs listed in this chapter.

When there are warranties in place it is strongly advised that the party liable for the warranties is not the only one calculating the KPIs.

Solar PV power plant data

Solar PV power plant data can be split into two groups:

1. Raw data measurements: data obtained directly from the solar PV power plant and used for performance calculation

2. Solar PV power plant KPIs: using the raw data from the solar PV power plant to give a more balanced overview of its operation

Raw data measurements for performance calculation

The following is a list of raw data measurements that can be used to calculate KPIs:

· AC Apparent Power produced (kVA)

· AC Active Power (kW)

· AC Energy produced (kWh)

· AC Energy metered (kWh)

· Reactive power (kVAR)

· Irradiance[1] (reference for the plant or the sub-plants) (W/m2)

· Air and module temperature (Celsius degrees)

· Alarm, status code and duration

· Outages, unavailability events

This is a basic list, and it is non-exhaustive.

Solar PV power plant KPIs

Calculated KPIs give a more balanced view of the operation of a solar PV power plant as they take into account the different operating conditions for each plant. Suggestions for calculated KPIs, along with relevant formulas, can be found below. These KPIs can be calculated over different time periods, but often they are computed on an annual basis. When comparing different KPIs or different solar PV power plants’ KPIs, it is important to be consistent in the time period used in computation.

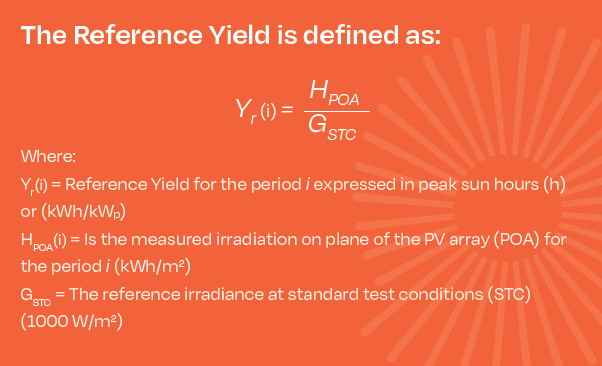

Reference Yield

The Reference Yield Yr represents the energy obtainable under standard conditions, with no losses, over a certain period i. It is useful to compare the Reference Yield with the final system yield.

Specific Yield

Specific Yield, also called final yield, Yf is the measure of the total energy generated, normalised per kWp installed, over a certain period i.

This measurement integrates plant output over a chosen time frame, and since it normalises to nominal power, comparison of the production of plants with different nominal power or even different technologies (e.g., solar PV, wind, biomass etc) is possible. For example, the Specific Yield of a solar PV power plant can be compared against the Specific Yield of a wind plant for the purposes of making an investment decision. Moreover, the Specific Yield of a 5 MWp ground mounted solar PV power plant can be compared directly to that of a 1 MWp double tracker power plant, for example.

Calculating Specific Yield on the inverter level also allows a direct comparison between inverters that may have different AC/DC conversion rates or different nominal powers. Moreover, by checking inverter level Specific Yield within a plant, it is possible to detect whether an inverter is performing worse than others.

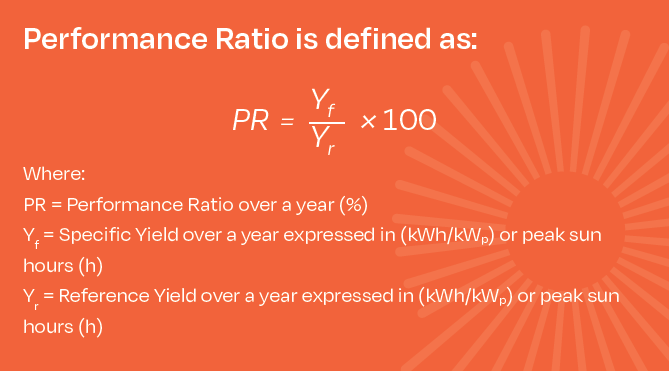

Performance Ratio (PR)

PR is a quality indicator of the solar PV power plant. As the ratio between the actual Specific Yield and the theoretically possible Reference Yield, PR captures the overall effect of solar PV system losses when converting from a nameplate DC rating to AC output. Typically, losses result from factors such as module degradation, temperature, soiling, inverter losses, transformer losses, and system and network downtime. The higher the PR is, the more energy efficient the plant is.

PR, as defined in this section, is usually used to report on longer periods of time according to the O&M contract, such as month or year. Based on PR, the O&M service provider can provide recommendations to the plant Owners on possible investments or interventions.

These definitions are based on (Woyte et al. 2014) in line with IEC 61724-1:2017 and are common practice.

PR is measured for available times at the inverter or plant level.

Note that special attention is needed when assessing the PR of overrated plants, where the output of the plant is limited by the inverter’s maximum AC output. In such situations, and for the period that overrating takes place, PR will calculate lower than normal although there is no technical problem with the plant. Stakeholders should be careful assessing PR values for overrated plants, although the amount of overrating is normally statistically constant or with negligible differences on a yearly basis.

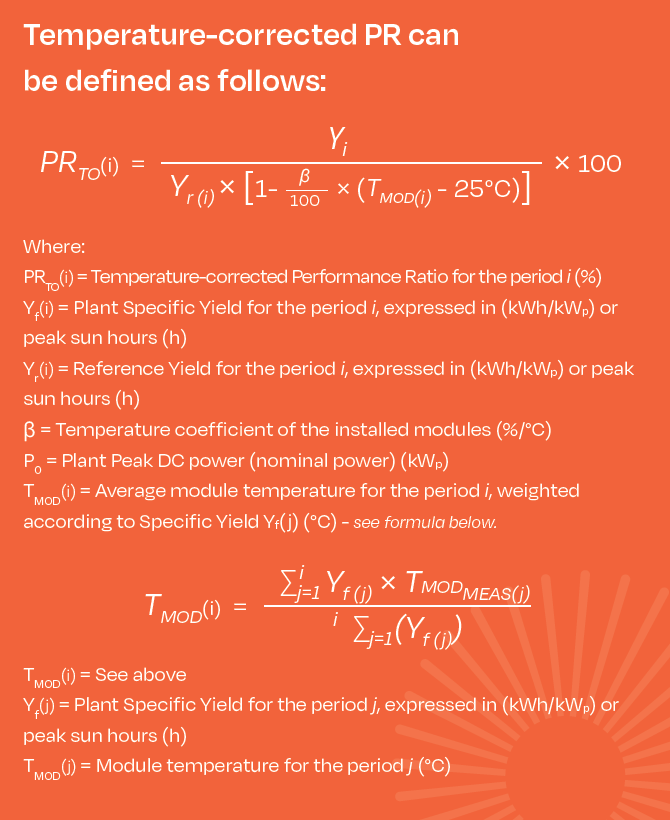

Temperature-corrected Performance Ratio

In some situations, such as a commissioning test or solar PV power plant handover from one O&M service provider to another, PR needs to be measured over a shorter period, such as two weeks or a month. In such situations, using a PR formula corrected with temperature factor is recommended. This can help neutralise short-term PR fluctuation due to temperature variations from STC (25°C). As a best practice, temperature should be registered with a granularity of up to 15 minutes (referred to as period j below) and the average temperature for the time period i should be calculated by weighting the mean temperatures of the time periods j according to Specific Yield of this time period.[2]

Interpreting Performance Ratio

Careful attention needs to be paid when interpreting PR, because there are several cases where it can provide misleading information about the status of the solar PV power plant:

Seasonal variation of PR (lower PR in the hot months, higher in colder months)

The calculation of PR presented in this section neglects the effect of solar PV module temperature on its power. Therefore, the performance ratio usually decreases with increasing irradiation during a reporting period, even though energy production increases. This is due to an increasing solar PV module temperature that results in lower efficiency. This gives a seasonal variation, with higher PR values in the cold months and lower values in the hot months. It may also give geographic variations between systems installed in different climates.

This seasonal variation of PR can be significantly reduced by calculating a temperature-corrected PR to STC, which adjusts the power rating of the plant at each recording interval to compensate for differences between the actual solar PV module temperature and the STC reference temperature of 25 °C (taking into account the temperature coefficient of the modules, given as % of power loss per °C).

Interpretation of PR for overrated plants (lower PR as designed)

Special attention is needed when assessing the PR of overrated plants. In these plants installed DC power is higher than inverter AC power (DC/AC ratio higher than 1), as a consequence, during sunny periods the output of the plant may be limited by inverter maximum AC output. In such situations, when derating takes place, PR will be lower than normal although there is no technical problem with the plant – lower PR in high-production periods is in fact the consequence of a design decision. Stakeholders should be careful assessing PR values for overrated plants, although the amount of derating is normally statistically constant or with negligible differences on a yearly basis.

Calculation of PR using GHI instead of POA (misleading higher PR)

Calculation of the PR using the Global Horizontal Irradiance (GHI) instead of in-plane (POA) irradiance is an alternative in situations where only GHI measurements are available. The PR calculated with GHI would typically show higher values which may even exceed unity. These values cannot necessarily be used to compare one system to another but can be useful for tracking the performance of a system over time and could also be applied to compare a system’s measured, expected, and predicted performance using a performance model that is based only on GHI.

Soiled irradiance sensors (misleading higher PR)

Special attention is needed when assessing the PR using data from soiled irradiance sensors. In this case, PR will present higher values and will give the false impression that the solar PV power plant is performing better than expected and even some underperformance issues could remain hidden.

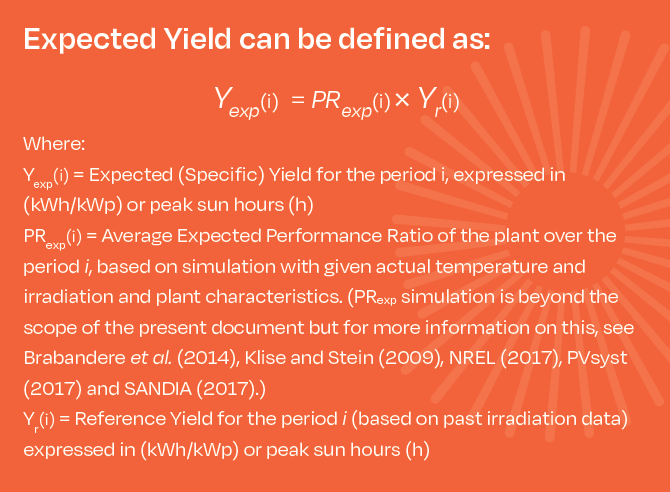

Expected Yield

Expected Yield Yexp(i) is the Reference Yield Yr(i) multiplied by the expected PR and thus expresses the Specific Yield that has been expected for a certain period i.

Note that Expected Yield is based on past values of irradiation data. Predicted Yield is based on forecasted data, from day ahead and hour ahead weather reports.

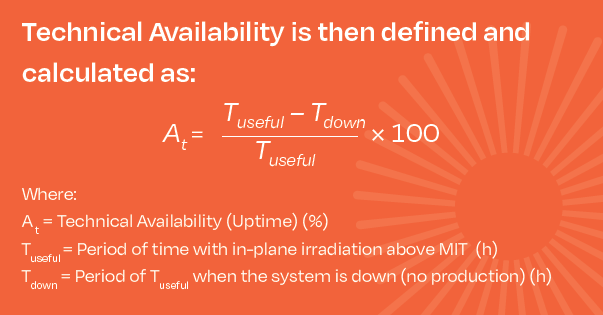

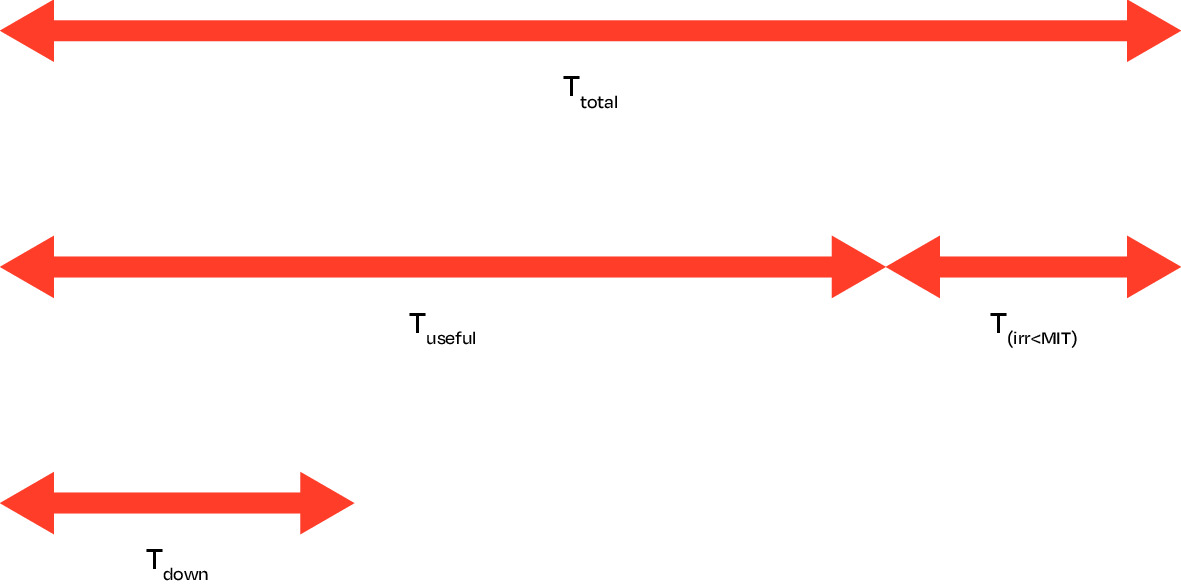

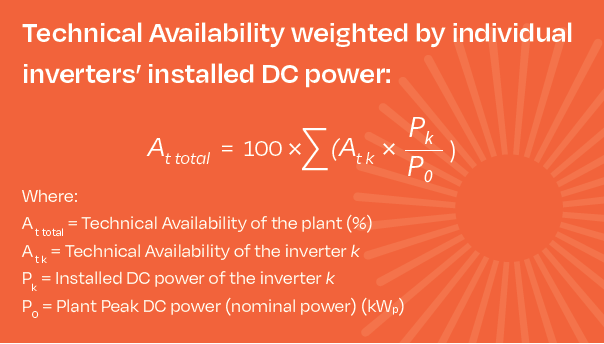

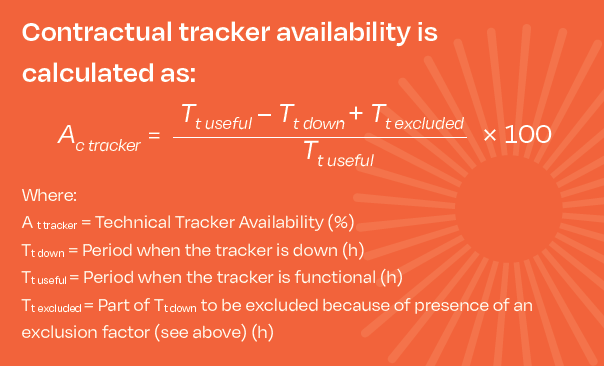

Energy Performance Index