Onboarding Best Practice Guidelines

Engineer/ architect

4.1. Development, engineering and procurement

Site assessment: related solar specific regulations

Before the beginning of the construction phase the different stakeholders, especially the investors and lenders, must assess the quality of the developed project, to come to a final decision to build the project, sign the relevant contracts and utter the notice to proceed (NTP). Then, the financial stakeholders have to choose an EPC service provider. Finally, the project has to be handed over to the EPC service provider without losing important information.

Selection of EPC projects

To select EPC projects and assess their quality, investors and lenders scrutinise certain factors, which often condense into checklists and internal guidelines (also called “ex-ante KPIs”). The content of this support strongly depends on several stakeholder traits (strategy, experience, etc.). For example, for one investor an activity in a certain region might be excluded, whereas another investor might be specialised in that region. Furthermore, the content of such support depends on the size of the project, while the complexity of the assessment will increase with project price. In the selection of the EPC project risk analysis and mitigation will play an important role.

Profitability

An important point for all stakeholders is the assessment of project profitability. Since the business plan needs to be realistic and solid, it is important to make sure that all important cost parameters have been considered. At least one yield study, done according to industry standards, should underpin expected production. Technical and legal due diligence studies must make sure that this production can be converted into revenue.

Quantitative assessment of a project’s profitability follows these qualitative verifications. An important KPI for a project’s profitability is the Internal Rate of Return (IRR). “Internal” refers to the fact that the calculation excludes external factors like inflation and cost of capital. According to the IRR formula, a project can be pursued if the internal rate of return is greater than the minimum required rate of return.

Technical Quality

One of the overarching engineering KPIs is expected performance ratio (PR) / expected yield, which is an input parameter into the business plan. Multiple parameters determine expected PR. We can only mention some of them here. A more detailed list is part of a technical due diligence / yield study. However, other aspects may be equally important, for example pre-qualification metrics (such as e.g., manufacturer, and main component ratings) and design rating.

Handover from project developer to EPC service provider

At the contracting stage, when selecting or appointing an EPC service provider, the developer should hand over all the important documentation about the project and preliminary works (see Annex F, section Basic Design – Development Documentation). This will be the basis for the scope of work negotiation with the EPC service provider and the share of responsibilities between the Asset Owner and the EPC service provider. The main topics to be discussed by both parties include the site description with its particularities, the permitting process and the associated constraints from legal authorities and the technical specifications from the grid connection side.

Site description (including site surveys and site data)

To ensure the best understanding and the most accurate design of the PV plant, a detailed description of the site and all associated constraints should be delivered to the EPC service provider. To pass on responsibilities to the contractor all preliminary studies and surveys should be shared. These documents will allow identifying the requirements and identifying the need for extended study. The main information to be shared is listed in Annex F, section Basic Design. If applicable, some documents from the Pre-Construction Documentation should also be considered.

Permitting process

Developers are typically in charge of obtaining building permits and all authorisations (e.g., from environmental authorities) related to executing works. EPC contracts should mention that service providers need to comply with any relevant permits and authorisations to maintain them. Specific aspects related to the construction period or design of a PV installation can be requested by the relevant authorities and it should be the service provider’s responsibility to provide these during the construction stage:

- Environmental mitigation measures to be implemented (plant trees, restoring grass, exclusion zones for levelling and grading works, measures towards flora and fauna)

- Aesthetic measures for visualisation of the project, landscape integration or sight impact on the neighbouring buildings (electrical cabinet design, height of structures, hedges to be planted)

- Fire and emergency mitigation measures

Grid connection process

The development stage also involves identifying the most suitable point of interconnection with the local network and the best strategy for connecting. This is often discussed at early stages with the network or grid operator, who is normally involved in the technical specification definition, and sometimes (in some countries systematically) in the completion of the works. To ensure timely grid connection and smooth communication between the network operator and the EPC service provider it is important to share the following:

- Grid connection technical specifications, often prepared by the local network operator

- Network operating conditions to be complied with during the operation phase

Additionally, in case of a specific Power Purchase Agreement (PPA), it is recommended that this information is shared with the EPC service provider. If commercial aspects need to be kept confidential then the technical specifications with which the EPC service provider has to comply should be shared, at the very least.

Engineering

The engineering design and modelling of a PV plant is a crucial element of the EPC lifecycle, as it guides the whole process of EPC, from conceptualisation to investment decisions and to the actual construction of the solar power plant. It is also a highly iterative process in which inputs from all the main stakeholders are considered, to generate the most suitable project plan for a successful and efficient PV plant.

As a best practice, all locally applicable standards and permitting procedures shall be clearly described and considered at the very start of the design process. Later, different stakeholders may have different engineering and design requirements to perform their respective services. Good communication and timely adjustments of the engineering design along the way are strongly recommended to ensure quality throughout the entire process.

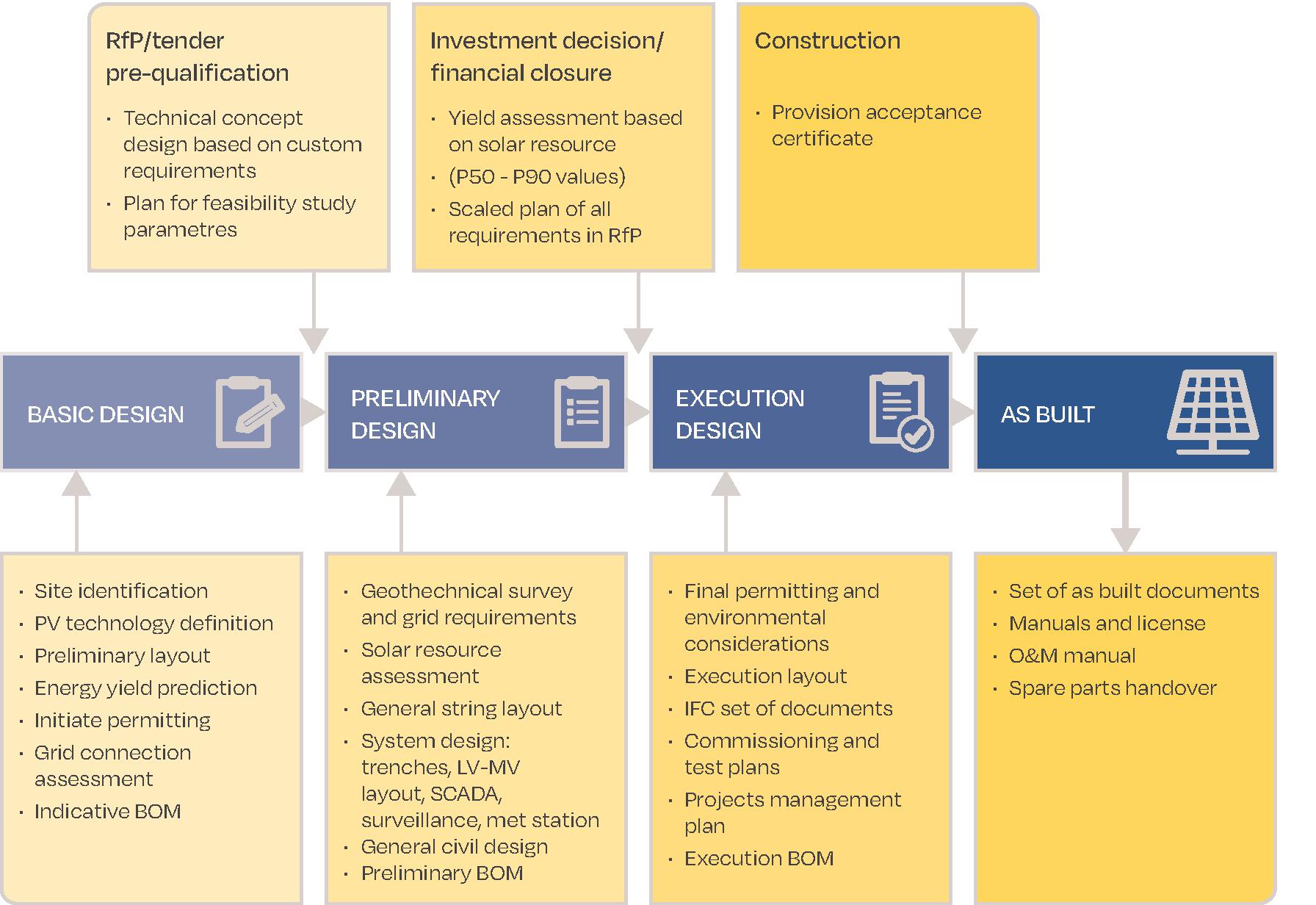

In the following chapter, the engineering stage of the project has been divided into four sub-phases, which are considered the common flow for PV project development. However, some of these phases (and milestones) may differ from the reader’s project due to different companies’ business approaches or philosophies, types of project finance, number of stakeholders and project size.

Starting off as a basic technical concept, the engineering design is itself a process that evolves and is constantly refined as the project development advances. It evolves into a detailed execution design blueprint issued for construction. Once construction and commissioning are completed, a detailed set of “as built” documents is handed over to the O&M service provider.

Basic design

The basic design concept is the first assessment of the engineering design, and it is sometimes considered to be a part of the early “project development”. At this stage, the developer may not have a clear understanding of the project site characteristics such as topography, hydrology, and obstacles. The main objective of the design concept at this early stage is to verify the project feasibility.

Generally, the basic design concept includes an initial layout (preliminary layout in Fig.14) for the plant, energy yield simulation, grid connection assessment and an indicative bill of materials (BOM in Fig.14) for the main components only:

- PV modules – manufacturer, model, and power class(es)

- Inverters - manufacturer and model

- Tracking system (if present) - manufacturer and model.

Using simulation software to compare different sets of module or inverter technologies, as well as mounting structures and different plant layouts can be beneficial in choosing the optimal design in terms of predicted energy yield and cost structure.

Usually, the basic design concept with total installed capacity, indicative layout design and single line diagram (SLD) is sufficient to start the permitting process.

However, more detailed versions of the basic design concept may be produced to facilitate early development permitting milestones or bidding in tender procedures, depending on the concrete case requirements.

Establishing design requirements and conducting requirement analysis are the most important elements in the design process, and this task is often performed at the same time as a feasibility analysis.

On top of basic things like the functions, attributes, and specifications, determined after assessing user needs, some design requirements may also include hardware and software parameters, maintainability, availability, and testability.

Maintainability requirements:

· The support structure should allow grass cutting, panel cleaning, and preserve a sustainable ecosystem

· There should be enough space between PV rows, and between rows and fences

· On roofs, there should be maintenance walkways

· The fixation of string cables should keep the connectors far from rain

· The drainage system should be designed to remove water in an efficient way without high OPEX and to avoid flooding

· The security system should be designed to allow for efficient protection of the plant at moderate OPEX

· The monitoring system should allow for quick error detection and efficient fault analysis (see SolarPower Europe’s O&M Best Practice Guidelines for requirements)

· It should be possible to have affordable service contracts for core elements like inverters and switch gear

As the project advances, the developer will acquire more information, provided that the following studies are performed: site assessment, solar resource analysis, environmental studies, permitting requirements and interconnection assessment.

The design can be updated respectively with:

· Preliminary Layout with Installed Capacity: Wp and Wac

· Layout constraints and boundaries

· Indicative bill of materials of major equipment: modules, inverters, type of structure, transformers

· Preliminary SLD

· Yield simulations with proposed losses assumptions for availability, soiling, cabling losses

Then, project documentation is ready for the technical due diligence usually required by investors, especially, if the power plant is financed through project finance.

An indicative list of documents is provided at the Annex F, section Basic Design, as a guideline for the developers on how to initiate a project, seek permitting and advance to the technical due diligence stage.

It is a best practice that the design development is done in close coordination with the stakeholders involved such as investors, local communities, banks, suppliers, grid operators, national and local authorities, etc. The more detailed and stakeholder-agreed the design is, the better it will support the development of the project’s financial model.

As a best practice, the technical viability of the design needs to be confirmed. The proposed suppliers of the main components need to be checked for a satisfactory track-record and relevant warranties. These steps are especially important when utility scale and commercial & industrial (C&I) projects are considered. Those financial stakeholders who do not have their own internal technical teams may instead rely on specialised technical advisors to conduct the relevant studies and reports and confirm the quality of the basic design.

Preliminary design

A detailed basic design usually provides sufficient basis for taking an investment decision or arranging finance. However, depending on the stakeholders involved, clearing that milestone may require more precise site topography measurements as well as regulatory and financial closure aspects to be accounted for in a preliminary design concept.

A key element of preliminary designs is a topographical survey. A ground-based site survey should be enhanced through a full topographical survey using a drone, which can produce site orthomosaics, Digital Elevation Models (DEM), and Point Cloud maps. Using a drone to collect the terrain and shading scene (both near and horizon) is vital in ensuring an optimal array design for a given area of land. If an EPC service provider is contemplating using bi-facial modules, then an albedo estimate can also be made from the drone photogrammetry.

Computer Aided Design (CAD) based software will ingest these 3D models to produce the topographical layouts of the PV plants where all elements are in their true geographical locations, to an extremely high level of accuracy and precision.

In any situation, the present section, and the Annex F, section Preliminary Design are an indicative guideline for the phase’s steps and documentation.

The preliminary design shall be part of the Pre-Construction Documentation, where the layout shall propose:

· PV Array sections

· Inverter Stations

· Mounting systems or trackers

· Substation

· Communication systems

· Monitoring systems

· Cable routes

· Access roads

· Laydown areas

· Meteorological stations

· Site tracks

· Manholes

· Construction area

· Permanent and temporary buildings

The preliminary design shall include a preliminary bill of materials (preliminary BOM in Fig.14) for budgeting purposes. The bill of materials gives quite a precise indication of quantities, so that (binding or non-binding) term sheets can be collected from suppliers and contractors.

The topographical survey and layouts of PV plants can be used as a 3D model to generate a preliminary digital twin of a PV plant, intended as a tool to visualise the asset. The information related to the choice and selection of components are part of the PV Information Modelling can also be visualised within the digital twin.

In projects where a turnkey EPC contract is signed, the design is only approved by the Asset Owner or the developer, and the EPC service provider is responsible for providing all the contracts and suppliers.

If an EPC service provider has already been involved in the design phase, the set of documentation shall include the projects’ buildings, amenities, preliminary studies, quality and testing plans, as well as the method statement, in addition to the layout and equipment specification.

At this stage, the Owner/Developer shall also agree with the EPC service provider on the Project Management Plan, including the project reporting, EHS, quality, changing plans and document register.

A detailed overview of the documentation of this stage can be found at Annex F, section Preliminary Design.

Execution design

As the preliminary design is changed and/or approved by the Owner, the EPC service provider shall move to the execution design stage, incorporating all the relevant construction blueprints and working instructions.

Once the design is finalised, it shall provide all the information necessary to request a grid connection, as well as all the necessary parameters for a grid impact analysis (if required).

A fully detailed specification of equipment and bill of materials (including the spare parts) shall be produced. As part of the execution design, the construction plans would have the final reports of calculations and assessments for all electrical and civil structures.

Factory acceptance plans shall be defined for major equipment. In addition, commissioning and testing procedures shall be provided to the Owner/developer for verification and approval.

It is recommended that a list of companies, major machinery, number of personal involved in the construction phase and quality assurance measures planned be included in project management plans. A method statement shall be clearly defined for each project phase.

A detailed overview of the documentation of the execution stage shall be found at Annex F, section Execution Design.

For large assets drone-based construction monitoring is recommended during construction. This data provides an excellent risk management tool and helps ensure the integrity of construction vs design plans by capturing any deviations or design changes as they occur.

As-built design

After the PV plant is accepted by the Asset Owner or the developer via the Provisional Acceptance Certificate (PAC), the project enters the handover stage. This is the phase of the project where the EPC service provider shall deliver all the design documentation that details how the PV plant has been built (as-built design documentation). This is important to emphasise, because during the construction phase some of the execution design may change due to unexpected events, mistakes on the design, terrain, or underground difficulties.

A dimensionally and geospatially accurate ‘as-built’ model of the asset can be generated from the drone-captured construction monitoring data, which can be used to update the digital twin. If construction monitoring has not been undertaken, then a single photogrammetry flight can produce an as-built record of the visible array layout. It is also possible to generate a 3D model of the new asset for onward yield modelling and verification by using more enhanced photogrammetry approaches. Such data capture and modelling can be valuable as part of the handover documentation from the EPC service provider to the Asset Owner and the O&M service provider.

A detailed overview of the as-built documentation can be found in Annex F, section As-built Design (consider also IEC standard 62446).

In addition to the as-built design, the EPC service provider should also organise other handover documentation, such as the O&M manuals, for the Asset Owner and the O&M service provider

Construction

In the construction phase, the solar power plant is installed based on installation manuals provided by suppliers to assure the proper storage, handling and installation of mounting systems, PV modules, inverters, transformers, cabling, monitoring system/sensors and other balance of system components. It also ensures the quality of the installation as well as the long-term stability of the PV system.

A proper schedule and preparation of several activities around the construction are important and should preferably be organised according to common project management techniques. This includes clear definition of objectives, activities, and responsibilities (who does what?), time plans and milestones (when?), cost planning, and quality assurance. To achieve this, an effective and efficient communication, documentation and reporting flow between the Asset Owner, the EPC service provider and the subcontractors is necessary. This will help encourage accountability, potential construction defects are promptly identified, high standards upheld, and monitoring the EPC service provider’s performance is easier.

The overall construction activity can be divided into two phases: firstly, the preparatory phase, related to the preliminary activities and secondly, the construction implementation phase, including site preparation, civil, mechanical, and electrical works necessary to complete the plant and bring it to the production phase.

Construction preparatory phase

The construction preparatory phase includes those planning and preparatory activities that ensure the smooth realisation of the PV plant. For this purpose, it is important that the construction project is correctly set up according to project management principles: the Asset Owner and the EPC service provider define project organisation and objectives, arrange main parts of the project in a work-breakdown structure (WBS), deduce a time schedule with clearly defined work packages, including responsibilities/accountabilities (responsibility matrix, for example, a RACI matrix), interdependencies, duration and resources. This time schedule shall be the reference for monitoring the project’s progress from both a physical and cost control perspective and needs to be regularly updated.

Site survey

The site survey aims at checking that there are no physical and geographical constraints or inconsistencies with the assumptions and technical details defined in the Execution design. If there are inconsistencies between the execution design and the site survey, the EPC service provider should consider doing another topographical survey with a drone.

The survey is also necessary for checking the actual status of the site and for planning the preliminary activities necessary to prepare the site for the mobilisation of personnel and equipment and the start of the main construction activities.

While the effective mobilisation of the EPC service provider and their subcontractors usually takes place once contracts enter into force (in general when a notice to proceed is issued by the Asset Owner), the execution of certain early works, sometimes also called preliminary works, is a project strategy that is becoming more frequent.

With reference to construction activities set-up, the key topics to be investigated during the site survey are:

- Mapping of the construction site (allotment and boundaries, topography, etc.)

· Definition of the area for temporary facilities and storage/warehouse

· Identification and mapping (geolocalisation) of interferences to be considered during construction, for which drones can be used

· Assessment of critical elements for construction and identification of mitigating actions (technical risks, rests of bombs, hazardous waste, but also archaeological discoveries)

· Detailed survey of transportation facilities and routing and other logistic items

· Execution of the pull-out test, necessary for the final test of the selected foundation design of the mounting structures

Stakeholder management

The primary tool for understanding the context in which the project is implemented is to identify and understand the stakeholders involved in, or affected by, the project. This allows one to become aware of their expectations and to determine the effective, potential, or perceived impact that the project can have on them identifying methods for involving them.

The identification of the stakeholders and their needs and expectations requires suitable knowledge of the relationships that exist between the different actors that are present and active in a given context. For this purpose, all subjects that could influence or be influenced by the project must be considered.

It is important that the identification of the stakeholders is not limited to local and administrative authorities but should also consider people and organisations that are relevant for local communities, as they represent their interests and identity.

Construction plan preparation

Construction Planning aims at planning all construction activities properly and guaranteeing that resources are available and scheduled consistently with activities. This avoids any unplanned stops.

After definition of the project scope of work, the project management team structures the project by organising the activities in a hierarchical structure, the Work Breakdown Structure (WBS). Only the activities identified with the WBS shall be within the project scope and, therefore, can be planned and controlled. There is only one WBS per project. A well-defined WBS:

· Provides complete definition of the project scope at different levels

· Allocates tasks and responsibilities

· Defines a numbering system, which is used as reference in project plans, reports, and technical documentation

· Provides an input to integrate cost and schedule data

· Ensures the alignment with the contracting execution strategy

· Facilitates the roll up of cost, progress, and schedule performance information for reporting purposes

All parties (the Asset Owner, the EPC service provider and other service providers) involved in the project should comply with the WBS and related coding system. Clear and effective communication between the Asset Owner, the EPC service provider and other service providers (and in general, all third parties involved in the project), and constant monitoring of the construction work progress according to the WBS, are key to ensuring full alignment on scope of work, objectives, deliverables, and timing.

WBS’s lowest hierarchical items are the work packages (WP). By defining each WP in detail and considering dependencies, the project plan is created. Each WP should contain at least the following information:

· Name

· Unique number/code

· Version and status information

· Description of content and results to be obtained

· Prerequisites and dependencies (deliverables required etc.)

· Projected duration

· Resource requirements (people, material, tools, vehicles, etc.)

· Person responsible for the WP

A detailed scheduling of the activities, including milestones, is essential to completing the work in a timely manner. Proper scheduling of the works is mandatory for correctly managing and controlling the progress of the project. If the work plan has not been prepared appropriately, mistakes and delays cannot be identified, and corrections cannot be implemented. Furthermore, the project plan needs to be updated regularly.

Project managers derive subordinate plans and documents from the central project plan. For example, the EPC service provider and other service providers will have planning, scheduling, reporting, and documentation obligations, according to the stipulated contract. With reference to the WBS, contractors should be responsible for the lower-level activities schedules and plans. A typical document for this phase is the mobilisation plan, which includes:

· Construction site organisation chart: the subcontractors (civil and electro-mechanical) need to provide the construction site organisation chart which indicates all the expected positions, the staff residence times and the expected hours.

· List of site vehicles and equipment: subcontractors must provide the list of vehicles and equipment they intend to use for different kinds of work, accompanied by certificates of suitability and maintenance and/or testing sheets.

Work plan and mobilisation plan guarantee in-time arrival and accommodation of construction site personnel and assembly materials. They also ensure that the different elements of the construction phase are properly coordinated.

Based on the defined project schedule (baseline), the associated physical progress curve should be determined, to establish a reference plan for the percentage of physical completion of the project at each date. This is key for proper project monitoring.

To calculate the project’s physical progress, one must define specific calculation rules to apply to each elementary activity type, as well as determine the weighting criteria.

The construction plan should also define processes and procedures relating to the interface of the construction team with the rest of the project staff, in particular with the engineering, EHS and quality management teams. It should be assured, for example, that all the project changes proposed by the EPC service provider and other service providers are checked and approved by engineering department (change management). Furthermore, the construction activities should be verified in accordance with the quality control plan and HSSE procedures (quality management). Other control activities concern cost/budget, HSSE compliance, documentation, etc.

Check and finalisation of works permits

Country-specific legislation and regulations around HSSE and construction activities are continuously evolving. It is critical to be sure that all works, administrative permits, and authorisations have been obtained to avoid breach of any legal provision. Such a breach could result in severe consequences, both in terms of personal and administrative sanctions and in downtime and delay in the execution of the activities.

A useful tool to ensure full compliance is the prescription and authorisation checklist which should identify all the relevant legislation and regulations applicable to the specific project and location. It also lists all requisites necessary to start the construction activities (authorisations, particular training requirements for certain works, such as works at height, land lease agreements, etc).

Activation of external suppliers (services and materials)

Once all preliminary activities have been assessed and completed, the construction activities are ready to start. All subcontractors and suppliers must be activated according to the specific clauses of the relevant contracts and based on the scheduled activities. The scope of this phase is to ensure that all resources are present at the site in a timely manner to avoid any downtime and delay.

Construction implementation phase

Construction site activities must be supervised by the EPC service provider’s Construction Manager. They should coordinate with the Asset Owner’s Construction Manager and the Construction Supervisor on the monitoring and control of subcontractors. Throughout construction, drone construction monitoring flights should be carried out periodically to monitor, record and report on construction progress and quality. The data from these scans can also provide valuable support to H&S, stock management, and adherence to local planning and environmental regulations.

Construction site organisation

Construction site organisation refers to the preparation of the site for the start of civil, mechanical, and electrical works.

The effective mobilisation of the EPC service provider and related subcontractors usually takes place approximately 60 days from the signature of the contract. However, preliminary site preparation and executive engineering may begin immediately after signing.

In the mobilisation phase, contractors will begin to mobilise direct and indirect labour, equipment and means so that all planned activities can start as scheduled.

Site preparation main activities are:

· Opening of the construction site

· Archaeological survey may be requested by local authorities depending on the historical interest of the site

· Removal of vegetation removal and the superficial part of soil where foreseen (this kind of activity should be minimal in accordance with a positive biodiversity strategy)

· Staking and beating of the poles of the structures

· Visual mitigation works planned

Civil works

Civil works refers to excavation for the construction of cable ducts, including foundation, MV overhead line supports, preparation of the areas where inverters and DC boxes will be installed, distribution station, road construction, and any earthworks in general.

They must be planned and implemented to minimise the interference and the overlap with the electro-mechanical activities described below, which are often difficult to manage from a safety point of view.

Biodiversity issues need to be considered (see section 3.2.1 on Biodiversity of the EPC Best Practice Guidelines) to minimise the impact of civil works. Where this is not possible, restoration or compensation measures should be taken, but it is always better to reduce destruction during works. Raising the awareness of personnel and clear guidelines can help to achieve this.

Electro-mechanical works

Mechanical activities mainly consist of:

· Withdrawal of materials from the Contractor warehouse

· Assembly of metal structures

· Installation of PV equipment / panels

· Package / cabin assembly

· Tests and inspections

Electrical activities mainly consist of:

· Laying ground network (equipotential bonding)

· Laying DC (LV) solar cabling and related components for connecting PV module strings to inverters using tools certified/qualified by the manufacturer for PV cable-connectors assembly. At present DC cabling configurations can vary a lot but nevertheless, laying DC cabling is a key element of the electrical works

· Laying MV cables from transformer stations to the distribution station

· Laying LV auxiliary cables

· Cabin and field connections

· Tests and inspections

Ancillary works

Ancillary works are activities that are not directly connected with the assembly of the “electric generation plant”. They refer in general to security (fencing, CCTV, lighting, …), vegetation care, internal roads, signposting, and so on and so forth.

These works, even if not prioritised, must not be underestimated because they could delay the handover of the entire plant.

Grid connection

Utility scale PV plants need to be connected to the network, usually managed by the Transmission System Operator (TSO). Connection complexity depends on the distance between the plant and the substation, its conditions and the technical solution identified for the connections. These works are the final stage of the construction activities and normally require the involvement of the TSO, which should be scheduled well in advance.

Checks and functional tests

Once the plant is completely built and connected to the grid, one must test that it works properly. It is important that tests are carried out according to a detailed procedure agreed between the EPC service provider and the Asset Owner.

To this end, the EPC service provider must send the Asset Owner a detailed plan of execution of all the work necessary to reach Start-up (Start-up Plan), before the start of the Mechanical Completion and Pre-Commissioning activities of the plant.

The plan should include the following minimum requirements:

· Definition of a start-up team

· Definition of the project functional units and related sub-units

· Definition of the plant sections that can be put into production in sequence

· Definition of the schedule and procedures for carrying out the preparatory tests for the start-up for each functional unit and plant section

· Description of how to perform the Mechanical Completion and Pre-Commissioning tests on the functional units

· Description of the execution of the Commissioning tests on the functional units and on the entire system

Mechanical completion

When the plant is completely built and connected to the grid, after a visual inspection, the Asset Owner issues the Mechanical Completion Certificate (MCC).

The aim of the visual inspection is to verify:

· That all components and materials are present and in accordance with the project documentation

· The compliance of the completed project with the project documentation, the Technical Specification, and the current legislation

· The electro-mechanical completion of the plant

· That all components are free of visible damages that could compromise the safety of the components and personnel

· That the components have been installed correctly

· The correct identification and labelling of all components such as inverters, DC boxes, cables, support structure rows, switches, communication devices, monitoring elements, etc.

· The correct execution of the connections

· An aerial survey to validate the asset against its design layout

Training of Asset Owner and O&M service provider

As soon as the plant is ready for operation, after MCC has been issued, the EPC service provider should arrange for a specific training for the Asset Owner and the O&M service provider’s personnel (that could be a third-party or the O&M division of the EPC service provider). This training can transfer the knowledge and philosophy with which the plant has been designed and constructed.

Training is important as it allow the O&M service provider’s staff to familiarise themselves with the plant and its operations. Poor training standards can result in lower performance of the plant, due to delays in detecting system malfunction signals, resulting in longer downtime as faults are resolved. This is also an opportunity for the O&M service provider to give feedback to the construction (and engineering) team, especially if both belong to the same company.

The Asset Owner’s personnel should also receive training. This will help avoid misunderstandings between the Owner and O&M service provider and make their collaboration more efficient and effective.

A comprehensive and detailed as-built documentation (Annex E of the O&M Best Practice Guidelines), manuals and procedures (Annex C “Documentation set accompanying the solar PV plant” of the O&M Best Practice Guidelines) should be part of the training activities.