Operation & Maintenance Best Practices Guidelines (Version 6.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchPower Plant Maintenance

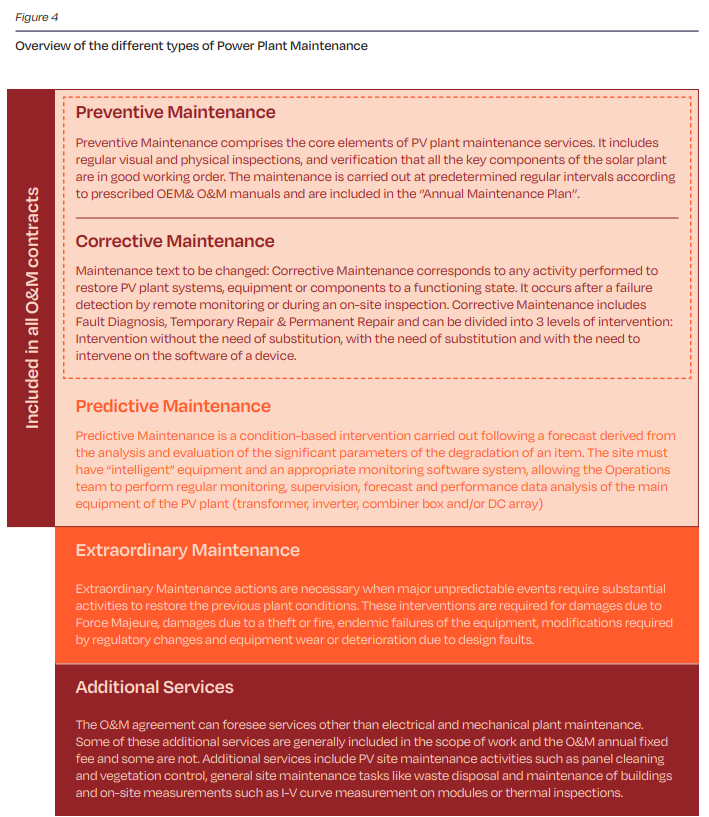

This chapter summarizes the critical aspects of maintenance in solar PV power plants, emphasising the collaboration between on-site technicians, subcontractors, and operations teams to ensure optimal performance. It covers various maintenance types—preventive, corrective, predictive, and extraordinary—highlighting their distinct roles and importance.

Maintenance is usually carried out on-site by specialised technicians or subcontractors, in close coordination with the Operations team’s analyses. In modern solar PV power plants, automation of maintenance tasks is becoming more prevalent. However, this practice is still developing and is not widespread currently. The following figure provides an overview of the four main types of power plant maintenance.

5.1. Preventive maintenance

Preventive Maintenance (also called “scheduled maintenance”) activities are the core element of the maintenance services to a solar PV power plant. It comprises regular visual and physical inspections, as well as verification activities.

The current standard is that maintenance of all key components is carried out at predetermined intervals or at least according to prescribed OEM and O&M manuals. These are included in a detailed Annual Maintenance Plan which provides an established time schedule with a specific number of iterations for carrying out the maintenance.

It must also maintain the equipment and component warranties in place and reduce the probability of failure or degradation. The activities must also be consistent with respective legal issues such as national standards for periodic inspection of certain electrical components, as well as asset insurance plans. This means that a number of varying factors (warranties, legal standards, insurance plans) influence the activities of the Annual Maintenance plan next to general maintenance considerations. The O&M contract should include this scope of services and each task frequency and ideally identify a priori which components to look at during the implementation of operation & maintenance activities.

It should be noted that the various maintenance activities require personnel qualified to carry them out. The O&M service provider must ensure that they have the appropriate range of skills available to fulfil their contractual obligations (for more information on maintenance activities and the skills they require, see Annex b of these Guidelines and Annex a of the Lifecycle Quality Guidelines).

The “Annual Maintenance Plan” (see Annex E or download it from www.solarpowereurope.org) developed as an attachment of this report includes a list of regular inspections per equipment (e.g. module, inverter etc) and per unit of equipment (e.g. sensors, fuses etc). In a component-cohort based approach, additionally to time and frequency activities are repeatedly performed on a pre-selected set of components in order to track the evolution of components over time.

Preventive Maintenance also includes ad-hoc replacement of parts of inverters or recalibration of sensors. In general, it is important to follow detailed Preventive Maintenance procedures, which are agreed upon in the Annual Maintenance Plan.

5.2. Corrective maintenance

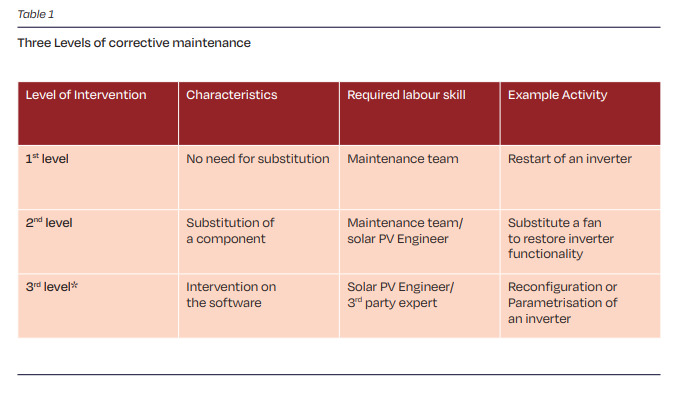

Corrective Maintenance covers the activities performed by the Maintenance team to restore a solar PV power plant system, equipment or component to a status where it can perform the required function. Corrective Maintenance takes place after a failure detection either by remote monitoring and supervision or during regular inspections and specific measurement activities (see Annex E).

Corrective Maintenance includes three activities:

- Fault Diagnosis also called troubleshooting to identify and locate the cause of the fault

- Temporary Repair, to restore the required function of a faulty item for a limited time, until a full repair is carried out

- Full repair, to restore the required function permanently

A key aspect of corrective maintenance is to be able to track failures to their root cause. This is most often a problematic manufacturer/model/serial number but may also be linked to installation errors or environmental conditions such as temperature inside enclosures. Corrective Maintenance processes should also track the efficacy of responses to problems (what fixes the problem reliably?)

3rd level activities could be included in the O&M agreement or billed separately to it, depending on the specific scope of work agreed between the parties. Generally, however, this intervention is excluded by the contractual scope of work, especially when the device manufacturers’ maintenance team or third-party licensed company needs to intervene.

Interventions for reconditioning, renewal, and technical updating, save for the cases where those actions are directly included in the scope of the contract, should be excluded from Corrective Maintenance, and included in the Extraordinary Maintenance (see 5.4. Extraordinary Maintenance).

The scope of Corrective Maintenance activities and its “border” or definition with respect to Preventive Maintenance requires specific attention and it should be properly defined in the Maintenance contract. For an easier comprehension, an example is presented below:

• A cable termination tightening activity using a torque device for correct fixation should be under the Preventive Maintenance scope of works, but depending on the quantity and/or frequency, it could be considered a Corrective Maintenance activity. The Annual Maintenance plan therefore states the extent of each planned activity.

Usually, Corrective Maintenance work must be accomplished within the contractually agreed minimum Response Times (see Chapter 10 section Response Time and Chapter 11 section Response Time price adjustment).

Contractual agreements can foresee that the included Corrective Maintenance will be capped on a per year basis.

5.3. Predictive maintenance

Predictive Maintenance is defined as a condition-based maintenance carried out following a forecast derived from the analysis and evaluation of the significant parameters of the degradation of the item (according to EN 13306). These parameters can be either based on a (1) monitoring software system or (2) on the analysis of tests and inspections carried out as part of the preventative maintenance and stored in a smart digital representation of the solar farm.

A prerequisite for a good Predictive Maintenance is that the devices on-site can provide information about their state, in such a way that the O&M service providers can evaluate trends or events that signal deterioration in a device. As a best practice, the device manufacturer should provide a complete list of status and error codes produced by the device, together with the detailed description of their meaning and their impact on the functioning of the device. Additionally, a standardisation of status and error codes through inverters and dataloggers from the same brand should be followed and, in the future, this standardisation should be common to all manufacturers.

The Operations Team should select “intelligent” equipment set with sufficient sensors and opt for a monitoring software system that provides basic trending and comparison (timewise or between components and even between solar PV sites) functionalities (minimum requirement).

The Operations team of the O&M service provider enables Predictive Maintenance thorough continuous or regular monitoring, supervision, forecast and performance data analysis (e.g. historical performance and anomalies) of the solar PV power plant (at the DC array, transformer, inverter, combiner box or/and string level). This can identify subtle trends that would otherwise go unnoticed until the next round of circuit testing or thermal imaging inspection and that indicate upcoming component or system failures or underperformance (e.g. at solar PV modules, inverters, combiner boxes, trackers., etc. level).

Predictive maintenance based on Component Condition Monitoring requires to first establish a digital representation of a solar site (digital twin), including a geospatial as well as an electrical and component-based understanding of the site. Within this digital representation it is crucial to rely on a standardised naming convention of all components, component properties (make, model, etc), as well as ideally component serial numbers.

Ideally, since these approaches don’t exclude each other, signals for predictive maintenance activities can be provided through both methods. Before deciding which Predictive Maintenance actions to recommend, the Operations team should implement and develop procedures to effectively analyse historical data and faster identify behaviour changes that might jeopardise systems performance. These changes of behaviour are usually related to the pre-determined or unpredicted equipment degradation process. For this reason, it is important to define and to monitor all significant parameters of wear-out status.

Following such analysis, the Maintenance team can implement Predictive Maintenance activities to prevent any possible failures which can cause safety issues and energy generation loss.

For efficient Predictive Maintenance, technical expertise is required, which is at best a combination of knowledge of the respective system’s performance, related equipment design, operation behaviour. Ideally, it is a process that starts at commissioning and the recreation of a baseline. This baseline will then represent the entire solar PV system operation, how different pieces of equipment interact with each other, and how the system reacts to “environmental” changes. Looking into the future, more and more automatic predictions will be provided by the respective systems, making this trend available also to less technically sophisticated O&M providers.

Predictive Maintenance has several advantages, including:

• Optimising the safety management of equipment and systems during their entire lifetime

• Helping to anticipate maintenance activities (both corrective and preventive)

• Delaying, eliminating and optimising some maintenance activities

• Reducing time for repairs and optimising maintenance and Spare Parts Management costs

• Reducing spare parts replacement costs

• Increasing availability, energy production and performance of equipment and systems

• Reducing emergency and non-planned work

• Improving predictability

The following four specific examples show how Predictive Maintenance might be implemented.

5.4. Extraordinary maintenance

Extraordinary Maintenance actions are necessary when major unpredictable events take place in the plant that require substantial activities and works to restore the previous plant conditions (or any maintenance activity generally not covered or excluded from the O&M Contract).

Extraordinary Maintenance interventions are required for:

• Damages that are a consequence of a Force Majeure event

• Damages resulting from theft or fire

• Serial defects or endemic failures on equipment, occurring suddenly and after months or years

from plant start-up

• Modifications required by regulatory changes

Additionally, in cases where the O&M service provider and the EPC service provider are different entities, the following occurrence should also be considered as Extraordinary Maintenance:

• Major issues that the O&M service provider becomes aware of during its ordinary activity. These could be defects or other problems that are not a consequence of equipment wear or deterioration and can be reasonably considered to have been caused by design mistakes (e.g. “hidden” defects that require re-engineering).

“Force Majeure” events affecting solar PV power plants include high winds, flooding, hurricanes, tornadoes, hail, lightning, and any number of other severe weather events. Extraordinary Maintenance associated with severe weather include safety shutdown, inspection to document damage, electrical testing (integrity of circuits and grounding), remove/repair/replace decisions, and recommissioning confirming proper operation and documenting changes made during repairs.

Generally, these activities are billed separately in the O&M contract and are managed under a separate order. It is advisable that the O&M contract includes the rules agreed among the parties to prepare the quotation and to execute the works. Both a “lump sum turn-key” or a “cost-plus” method can be used for such purposes.

Although not necessarily maintenance interventions, revamping and repowering can also be included in the Extraordinary Maintenance list in the O&M agreement, or at least managed with the same rules. For more information on this, see Chapter 7. Revamping and Repowering.

After the approval by the Asset Owner of the O&M service provider’s proposal, activities may commence, subject to availability of the required equipment and special machinery (if required).

The potential loss of energy between the event occurrence and full repair is very difficult to determine in the SPV financial model. However, many of the above events can be reimbursed to the Asset Owner by the insurance company under any “All Risk Insurance” coverage that is in place. Relevant conditions and requirements according to the insurance policies of the Asset Owner need to be shared with the O&M service provide.

Best Practices of O&M agreements regarding Extraordinary Maintenance activities include:

• General rules to quantify price and to elaborate a schedule to perform repair activities, and the right of the Asset Owner to ask for third party quotations to compare to the quotation of the O&M service provider. In this case a “right-to-match” option should be granted to the O&M service provider

• The obligation for the Asset Owner to have in place a consistent “All Risk Property” Insurance including loss of profit