Operation & Maintenance Best Practices Guidelines (Version 6.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchPower Plant Operation

Operations concerns remote monitoring, supervision, control of the solar PV power plant, and technical performance optimisation. It also involves subcontracting and coordination of maintenance activities. Power plant operation used to be a more passive exercise in the past, but with increasing grid integration efforts, more active and flexible operation will be required by grid operators. Examples include ordered shutdowns, power curtailment, frequent adjustment of settings such as power factor (source reactive power), frequency tolerances, and voltage tolerances. This section gives an overview of the operation tasks and requirements.

The following figure provides an overview of the most important tasks associated with power plant operation.

4.1. Document Management System (DMS)

Solar PV power plant documentation is crucial for an in-depth understanding of the design, configuration, and technical details of an asset. It is the Asset Owner’s responsibility to provide those documents and, if not available, they should, as best practice, be recreated at the Asset Owner’s cost.

Before assuming any maintenance and/or operational activities, it is important to understand in-depth the technical characteristics of the asset. There are two important aspects related to the management of this information:

- Information type and depth of detail / as-built documentation

- Management and control

Moreover, for quality / risk management and effective operations management a good and clear documentation of contract information, plant information, maintenance activities and asset management are needed over its lifetime. This is what is called here:

- Record control (or records management)

Currently, there are different types of DMS available, along with a series of standards (ISO), that can be implemented. This is an important requirement that would allow any relevant party to trace any changes during the lifetime of the plant’s operation and follow up accordingly (e.g., when the O&M service provider changes, or the teams change, or the plant is sold etc.).

4.1.1. Information type and depth of detail/as-built documentation

The documentation set accompanying the solar PV power plant should, as a best practice, contain the documents described in Annex C. The IEC 62446 standard also covers the minimum requirements for as-built documentation.

In general, for optimum service provision and as a best practice, the O&M service provider should have access to all possible documents (from the EPC phase). The Site Operating Plan is the comprehensive document prepared and provided by the plant EPC service povider, which lays out a complete overview of its location, layout, electrical diagrams, components in use and reference to their operating manuals, HSSE rules for the site and certain further topics. All detailed drawings from the EPC service provider need to be handed over to the O&M service provider and being stored safely for immediate access in case of solar PV power plant issues or questions and clarifications with regards to permits and regulation.

When storing documents, thought must be given to accessibility. As a minimum, project documentation should be available in a searchable PDF format to facilitate the identification of key information. Moreover, project drawings, such as the as-built design, should be editable in case they need correcting, or change management processes mean they need to be updated.

4.1.2. Management and control

Regarding the document control, the following guidelines should be followed:

- Documents should be stored either electronically or physically (depending on permits/regulations) in a location with controlled access. Electronic copies should be made of all documents, and these should be searchable and editable.

- Only authorised people should be able to view or modify the documentation. A logbook of all the modifications should be kept. As a best practice, logbooks should at a minimum contain the following information:

- Name of person, who modified the document

- Date of modification

- Reason for modification and further information, e.g., link to the work orders and service activities

- Versioning control should be implemented as a best practice. People involved should be able to review past versions and be able to follow through the whole history of the document. The easiest way to ensure this is through using an electronic document management system, which should be considered a best practice

4.1.3. Record control

A key point is that necessary data and documentation are available for all parties in a shared environment and that alarms and maintenance can be documented in a seamless way. Critical to the Operations team is that the maintenance tasks are documented back to and linked with the alarms which might have triggered the respective maintenance activity (work order management system log). Photographs from the site should complement the documentation (when applicable). Tickets (ticket interventions) should be stored electronically and made available to all partners. The Asset Owner should also maintain ownership of these records for future references.

To improve future performance and predictive maintenance, it is crucial to keep a record of past and ongoing O&M data, workflows and alarms. This record should seek to link these elements in a cost-effective way, following an agreed naming convention. This will improve accessibility and allow for easier tracing, facilitating comprehensive lessons learned exercises, and resulting in concrete future recommendations for the client. These analyses should also be recorded.

There should be proper documentation for curtailment periods as well as repair periods when the plant is fully or partly unavailable. This will all be recorded by the monitoring system to measure the energy lost during maintenance activities. For this, having the correct reference values at hand is crucial. For important examples of input records that should be included in the record control, see Annex D.

As in the case of the as-built documentation, all records, data and configuration of the monitoring tool, and any sort of documentation and log that might be useful for proper service provision must be backed up and available when required. This is also important when the O&M service provider changes.

4.1.4. Plant performance monitoring and supervision

The Operations team of the O&M service provider is responsible for continuously monitoring and supervising of the solar PV power plant conditions and its performance. This service is done remotely using monitoring software systems and/or plant operations centres. The O&M service provider should have full access to all data collected from the site to perform data analysis and provide direction to the Maintenance service provider/team. For more information on monitoring tools please refer to SolarPower Europe’s Monitoring Best Practice Checklist (available at www.solarbestpractices.com).

Besides the data from the site, if a CCTV system is available on-site, the O&M service provider should, as a best practice, be able to access it for visual supervision and also have access to local weather information.

The O&M service provider is responsible for being the main interface between the plant Owner, the grid operator, and the regulator (if applicable) over the lifetime of the O&M contract regarding production data. The Asset Owner should be able to contact the Operations team via a hotline during daytime, when the system is expected to generate electricity. The Operations team is also responsible for coordinating accordingly with the Maintenance service provider/team.

For more information on monitoring requirements, see Chapter 9. Data and monitoring requirements.

4.2. Fault Management

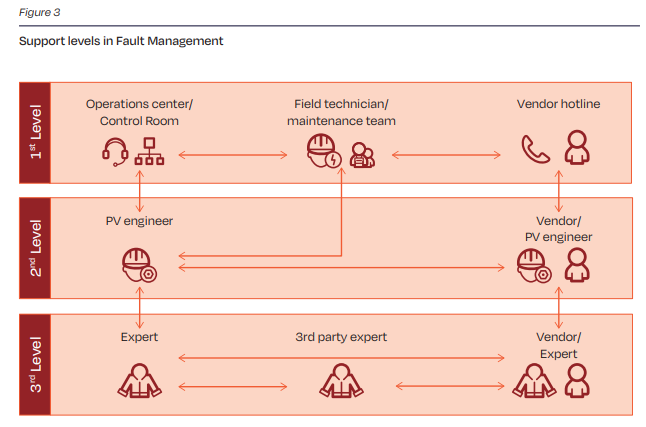

Fault Management involves the detection, categorisation, and resolution of incidents through a structured support system. Multiple levels, from 1st Level Operations to specialised 3rd Level Support, coordinate efforts to ensure timely fault resolution and maintain system performance.

Normally, in Fault Management (Incident Management) several roles and support levels interact:

- With the help of monitoring and its alarms the Operations Center (Control Room) detects a

fault. It is responsible for opening a “ticket” and coordinating troubleshooting actions. It collects

as much information and diagnostics as possible to establish initial documentation, tries

to categorise the issue and, where possible, to resolve it instantly. This is known as 1st Level

Support. Then it tracks the incidents until their resolution

• If the fault cannot be sufficiently categorised, the Operations Center may call out a field

technician who can be a local electrician or member of the maintenance team. This person

will analyse and try to resolve the fault on-site (1st Level Support). Their knowledge and access

rights may be not sufficient in some situations, but they can fix most faults to an adequate

level. They may also contact the vendor’s hotline to help them with the diagnosis

• If 1st Level Support is not able to resolve the incident right away, it will escalate it to 2nd Level

Support. This consists of solar PV engineers or Project/Account Managers who have greater

technical skills, higher access permissions, and enough time to analyse the fault in depth. They

may be internal or of the vendor’s staff

• If an incident requires special expertise or access, 2nd Level engineers might need to contact

experts (in-house or from the vendor or a third party). This is known as 3rd level support. In

some organisations the Project/Account Managers can cover both 2nd and 3rd Level Support,

based on their seniority and experience

• When the fault is solved, the Operations Center closes the ticket

4.2.1. Performance analysis and improvement

The O&M service provider ensures that the performance monitoring is done correctly.

In general, the data should be analysed at the following levels:

1. Portfolio level (group of plants) under control of the O&M service provider (minimum

requirement)

2. Plant level (minimum requirement)

3. Inverter level (minimum requirement)

4. String level (as a recommendation)

5. PV Module Level (as a further recommendation)

The analysis should show the required data on the levels listed above and for different time aggregation periods from the actual recording interval up to monthly and quarterly levels. The analysis should also include the option for having custom alarms based on client specific thresholds such as business plan data or real-time deviations between inverters on-site.

In particular, the agreed KPIs should be calculated and reported (see Chapter 10. Key Performance Indicators). Special attention should be paid to the fact that KPI calculations should take into consideration the contractual parameters between O&M service provider and Asset Owner, to provide an accurate and useful calculation for evaluation and eventually liquidated damages or bonuses.

4.2.2. Optimisation of O&M

An essential part of Operations is the analysis of all the information generated throughout O&M, such as Response Time, and how this correlates to the various classifications of events and root causes. Another vital part of Operations is the analysis of costs incurred for various interventions, categorised into materials and labour. Having such information helps to further optimise the asset by reducing production losses and the cost of O&M itself. For more information on optimisation of O&M please refer to Chapter 5. Power Plant Maintenance and Chapter 8. Spare Parts Management.

Further optimisation of O&M will be based on upcoming solutions in using AI and Big-Data-Analysis, which will be able to suggest optimisations based on recorded data of the actual and similar PV plants

4.2.3. Power plant controls

If applicable, the Operations team can be the point of contact for the grid operator for plant controls. The Operations team will control the plant remotely (if possible) or instruct the qualified maintenance personnel to operate breakers/controls on site. The O&M service provider is responsible for the remote plant controls or emergency shutdown of the plant (if possible) and in accordance with the respective grid operator requirements (see also below section on Grid code compliance), regulations, and the aggregator’s requirements. The plant control function varies from country to country and in some cases from region to region. The respective solar PV power plant control document for the area details regulations issued by the grid operator and (energy market) regulator.

The Power Plant Controller itself is a control system that can manage several parameters such as active and reactive power and ramp control of solar PV power plants. The set points can normally be commanded either remotely or locally from the Supervisory Control And Data Acquisition System (SCADA). Moreover, the system should be password protected and log all the executed commands. Any executed commands should release real-time notifications to the Operations team.

The following list shows typically controlled parameters in a solar PV power plant:

• Absolute Active Power Control

• Power Factor Control

• Ramp Control (Active and Reactive Power if needed)

• Frequency Control

• Reactive Power Control

• Voltage Control

• Control of Grid Code related parameter

4.2.4. Power Plant Control Layers

Effective solar PV plant operation hinges on a well-defined power plant control strategy. This strategy dictates how the plant responds to grid requirements while optimising energy production. Control policies should clearly differentiate between technical and commercial considerations, grid stability & equipment safety being core priorities before commercial behaviour.

Overall, there are three key layers to consider: dynamic local power control, centralised power control linked to curtailment and remote decentralised power control for grid commands. At the basis, local control the safe and efficient operation of the plant itself. It manages parameters like inverter output and internal voltage regulation. Centralised Power Control meanwhile is divided between curtailment decisions at the level of the aggregator, and those related to grid control which happen in a more immediate time horizon. For the aggregator, the focus is on grid stability and market participation. The aggregator, may remotely adjust power output based on pre-determined curtailment policies. Curtailment refers to the intentional reduction of power generation, typically triggered by grid constraints or economic factors. On the other hand, the grid operator may issue controls, prioritising grid security and stability which supersede aggregator or local control settings.

By understanding these control layers, policy distinctions, and technical considerations, plant operators can ensure a balance between grid needs, commercial interests, and optimal solar PV power plant operation.

4.2.5. Power Generation Forecasting

Forecasting services for solar PV power generation are generally offered by operators of solar PV monitoring services. However, external services can also provide this function. When the Asset Owner requires Power Generation Forecasting from the O&M service provider, they could opt for a service level agreement with the forecast provider. Forecasting may have an influence on the contract agreement for electricity dispatching between the Asset Owner and a trading service provider.

The requirements for forecasts may differ from country to country and also depend on the contract agreement for electricity dispatching between the Asset Owner and a trading service provider. Forecast requirements are characterised by the forecast horizon, the time resolution, and the update frequency, all depending on the purpose. For power system or power market related purposes, forecast horizons are typically below 48 hours, and the time resolution is 15 minutes to one hour, in line with the programme time unit of the power system or the market. Common products are day-ahead forecasts, intra-day forecasts and combined forecasts. Day-ahead forecasts are typically delivered in the morning for the next day from 0 to 24 and updated once or twice during that day. Intraday forecasts are delivered and updated several times per day for the rest of the day and should be delivered automatically by the forecast provider.

For long-term planning of unit commitment and maintenance decisions, forecasts with longer time horizons are used, typically one week or more.

Solar PV Power Generation Forecasts rely on numerical weather predictions, satellite data and/or statistical forecasting and filtering methods. Most products combine several of these techniques. Good practice requires numerical weather predictions for day-ahead forecasting and a combination with satellite data for intra-day forecasts. In all cases, good practice requires statistical filtering which in turn requires a near-real-time data feed from the monitoring system to the forecast provider. For best practice, the forecast provider should also be informed about scheduled outages and the expected duration of forced outages.

The most common KPIs for forecast quality are the Root Mean Square Error (RMSE) and the Mean Absolute Error (MAE). They are normalised to peak power and not to energy yield.

4.2.6. Grid code compliance

The O&M service provider, and in particular the Operations team is responsible for operating the solar PV power plant in accordance with the respective national grid code. The operator of the grid to which it is connected (either low voltage grid or medium voltage grid or high voltage grid) provides the requirements for power quality, voltage regulation and management of active and reactive power. In some countries (and/or regions) specific grid codes for renewable energy generators have been issued. Specific behaviour in exceptional grid conditions, e.g. reaction on short circuits and similar under-/overload conditions require stable operation and active grid support by GFM (grid forming) are upcoming requirements in grid code standards on national, regional and international levels.

Depending on the voltage level of the grid the plant is connected to, the specificities and quality requirements for the solar PV power plant change. Grids with a higher voltage level usually have more specific and demanding requirements.

Most of the grid-connected utility-scale solar PV power plants in Europe must undergo an external test to meet the grid operator requirements. These plant tests allow the grid operator to adjust the power output from the solar PV power plant according to the grid capacity and power frequency requirements.

The O&M service provider is expected to be familiar with all the details of the grid code and grid operator requirements. Depending on the regulations, either the grid operator themselves is steering the solar PV power plant controller (with remote signals) or the Operations team is managing the plant controller under the direction of the grid operator.

4.2.7. Management of change

If the design of a solar PV power plant needs to be adjusted after the Commercial Operation Date, the O&M service provider should, as a best practice, be involved by the Asset Owner and the EPC service provider. They can even be a main contributor, if not the leader, of this change process. Reasons for such changes can be motivated by non-compliance of the solar PV power plant with the capacity predicted by the EPC service provider, by regulation change (introduction of new solar PV power plant controls regulations), by the unavailability of spare parts or components, or for an upgrade to the solar PV power plant. These events can trigger new design works, procurement and installation of new equipment and adjustment of O&M procedures and/or documentation. It may also impact certain performance commitments or warranties provided by the O&M service provider, which will need to be adjusted.

The O&M service provider should be involved in changes to the solar PV power plant from the beginning. Concepts, design works, and execution need to be coordinated with ongoing O&M activities. Any changes should also be reflected in the plant SCADA and monitoring systems. For data continuity and long-term analysis, the monitoring system should be able to trace all changes of electrical devices. This should include documentation of inverter replacement date, manufacturer and type, and serial number in a structured way for further analysis (e.g. spare part management, Predictive Maintenance analysis). The monitoring of replaced devices will also help the O&M service provider verify that the new component is correctly configured and is sending high quality data. Adjustments to the Site Operating Plan, the Annual Maintenance Plan and the Annual Maintenance Schedule need to be applied, and the O&M service provider needs to familiarise the O&M staff with the operating manuals of the new equipment. These types of changes will have an impact on Spare Parts Management and inventory (replacement). Depending on the significance of the change, the O&M annual fee might need to be adjusted.

It is advisable that the O&M service provider lead these sorts of change processes. The O&M service provider is the trusted partner of the Asset Owner and should advise the Owner when they are making decisions on changes to the plant. In the case of major changes, the Owner should also consider informing lenders about the decision process and provide concepts, proposals, calculations and updates.

The fixed O&M fee does not usually cover change services. The Asset Owner and the O&M service provider should manage changes in a formalised way. This procedure should include the following steps: description of proposed change (including time plan, costs, consequences, and alternatives), authorisation of the change by the Asset Owner, realisation of the change, documentation by the O&M service provider and acceptance.

4.2.8. Power plant security

It is important that the solar PV power plant, or key areas of it, are protected from unauthorised access. This serves the dual purpose of protecting the plant’s equipment and keeping members of the public safe. Unauthorised access may be accidental with people wandering into the plant without realising the dangers, or it may be deliberate for the purposes of theft or vandalism.

Together with the O&M service provider and the security service provider, the Asset Owner must put in place a Security Protocol in case an intrusion is detected. In most countries there are strict legal requirements for security service providers. Therefore, solar PV power plant security should be ensured by specialised security service providers subcontracted by the O&M service provider. The security service provider will be responsible for the proper functioning of all the security equipment including intrusion and surveillance systems. They are also responsible for processing alarms from the security system by following the Security Protocol and the use of the surveillance systems installed on site. The security system provider will be also responsible for any site patrolling or other relevant services. The security service provider should also assume liability for the security services provided. The O&M service provider will coordinate with the security service provider and may choose to act as an intermediary with the Asset Owner.

A security system may be formed of simple fencing or barriers but may also include alarm detection and alerting systems and remote closed-circuit television (CCTV) video monitoring. If solar PV power plants have CCTV systems in place, an access protocol would be required when reactive and planned works are carried out. This will ensure that authorised access is always maintained. This can be done by way of phone with passwords or security pass codes, both of which should be changed periodically.

For additional security and in high-risk areas it is advisable to have a backup communication line installed (often, the first thing that gets damaged in case of vandalism is communication with the surveillance station) as well as an infrastructure for monitoring connectivity and communication with the security system. As well as any remote monitoring, it is likely that provision for onsite attendance is required when significant events occur. Processes for liaising with local emergency services should be considered.

Within the solar plant, there may also be additional areas with restricted access, for example locations containing Hazardous Voltage equipment. When authorising access to the parks it is important that all workers and visitors are appropriately informed of the specific access and security arrangements and where they should keep off. Warning signs and notices can form an important part of this and may be compulsory depending on local regulations.

As well as the general security of the site over the lifetime of the park, particular attention should be made to periods of construction or maintenance when usual access arrangements may be different. It is important that security is always maintained particularly when there are activities that may be of more interest to members of the public or thieves.

The Asset Owner will likely have insurance policies in place directly or indirectly and these will be dependent on certain levels of security and response being maintained. Failure to meet these may have important consequences in the case of an accident or crime.

4.3. Reporting and technical asset management

The Operations team is responsible for providing periodic reporting to the AM or directly to the Asset Owner. In many cases, the Operations team also assumes further TAM responsibilities. For more details on reporting and other TAM tasks, see SolarPower Europe’s report Asset Management Best Practices Guidelines V.2 (www.solarpowereurope.org)

4.4. Cooperation with Distribution System Operator (DSO)

The O&M contractor (or its dedicated department, like Control Center) should be appointed as the first to contact and the most important stakeholder (representative) for DSO in order to perform Operations at power plant that affects the grid connections or production.

Contacts between O&M provider and DSO should be regulated by the agreement between plant owner and grid operator while investments preparation. Contact list with all employees from O&M service provider and operators from DSO should be actualised every time when personnel changes.

DSO should inform O&M provider about any anomalies on grid that requires any operations on the grid like connection/disconnecting form a grid, stopping generation or limiting generation. Also, every time if O&M provider needed to disconnect plant form a grid for example to prepare workplace need to inform DSO in advance.

Works performed by O&M provider, but on “grid side” need to have a permission from DSO, because they are responsible for a grid quality, while O&M service provider should ensure safety workplace.

All O&M provider employees needed to have qualifications for electric operations and also necessary experience.