Engineering, Procurement & Construction Best Practice Guidelines (Version 2.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchTransition from project development to EPC

Project requirements are generally set up during the development phase (which precedes the EPC phase). They are mainly regulated under project development agreements. These are executed between the Special Purpose Vehicle (SPV), as the Owner of the project (or the Asset Owner, when the SPV has not been established yet), and the local developer who is in the early development phase conducting the initial engineering activities including the setup of the layout. In addition to technical activities, the developer is also responsible for filing all the requests for the necessary authorisations and construction permits with the competent public administrations. For these reasons, the role of the EPC service provider is marginal in the early development stage. This is confirmed by the fact that the layout and the other prescriptions to be met are generally outside the EPC service provider’s scope of work.

Therefore, in the present Guidelines, only three points are discussed because they are important for the transition from the development to the EPC phase:

- Before the beginning of the construction phase the different stakeholders, especially the investors and lenders, must assess the quality of the developed project, to come to a final decision to build the project, sign the relevant contracts (see Chapter 12 on Contractual framework) and utter the notice to proceed (NTP). Section 5.1 on the Selection of EPC projects discusses some relevant points of this type of assessment

- Then, the financial stakeholders have to choose an EPC service provider. Section 5.2 on the Selection of the EPC service provider discusses some important selection criteria

- Finally, the project has to be handed over to the EPC service provider without losing important information. Chapter 5.3 on the Handover from project developer to EPC discusses this critical procedure

5.1. Selection of EPC projects

To select EPC projects and assess their quality, investors and lenders scrutinise certain factors, which often condense into checklists and internal guidelines (also called “ex-ante KPIs”). The content of this support strongly depends on several stakeholder traits (strategy, experience, etc.). For example, for one investor an activity in a certain region might be excluded, whereas another investor might be specialised in that region. Furthermore, the content of such support depends on the size of the project, while the complexity of the assessment will increase with project price. In the selection of the EPC project risk analysis and mitigation will play an important role. For more information see Chapter 2. Risk Management: from Ready-to-build until COD.

5.1.1. Profitability

An important point for all stakeholders is the assessment of project profitability. Since the business plan needs to be realistic and solid, it is important to make sure that all important cost parameters have been considered. At least one yield study, done according to industry standards, should underpin expected production. Technical and legal due diligence studies must make sure that this production can be converted into revenue.

Quantitative assessment of a project’s profitability follows these qualitative verifications. An important KPI for a project’s profitability is the Internal Rate of Return (IRR). “Internal” refers to the fact that the calculation excludes external factors like inflation and cost of capital. According to the IRR formula, a project can be pursued if the internal rate of return is greater than the minimum required rate of return.

5.1.2. Technical Quality

One of the overarching engineering KPIs is expected performance ratio (PR) / expected yield, which is an input parameter into the business plan. Multiple parameters determine expected PR. We can only mention some of them here. A more detailed list is part of a technical due diligence / yield study. However, other aspects may be equally important, for example pre-qualification metrics (such as e.g., manufacturer, and main component ratings) and design rating.

The technical quality of a project depends strongly on procurement decisions. For more information, see Chapter 7 on Procurement.

5.2. Selection of EPC service provider

The following criteria (also called “ex-ante KPIs”), among others, help to assess EPC service providers: financial stability, expertise, prices, and procurement performance.

5.2.1. Financial stability

One important factor is the financial stability of the EPC service provider. It is important to get as close as possible to the present-day financial situation of the company. Credit ratings (seen in relation to the country/market the EPC service provider operates in) as well as audited statements from the last 2-3 years are typically the most solid and indisputable financial information. Since accounting definitions can vary from country to country, comparisons might be difficult.

An alternative to this is a bank guarantee where the investor moves the evaluation over to a bank partner. This does not necessarily give a better evaluation of the financial viability than one’s own evaluation, but it gives the financial insurance of a bank. This obviously comes with a cost. The mere demand for a bank guarantee can be prohibitive for some projects and can eliminate smaller, competent EPC service providers from participating, even though they are financially solid for their size.

Assessment of the following four areas provides insight into the financial situation of a company: liquidity, solvency, operating efficiency, and profitability.

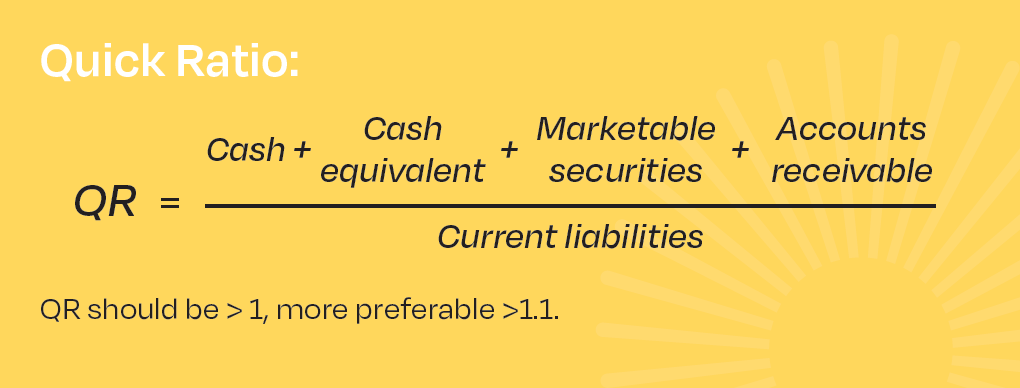

An important KPI for liquidity is the quick ratio (also referred to as acid test). It is defined as the ratio between quickly available or liquid assets and current liabilities.

Solvency is a company’s ability to meet its debt obligations on an ongoing basis, not just over the short term. The debt-to-equity ratio (D/E) indicates the relative proportion of shareholders’ equity and debt used to finance a company’s assets. The lower the D/E ratio, the more of a company’s operations are being financed by shareholders who do not charge interest, but more importantly, may enable the company to raise debt capital in case needed. On the flipside, a decreasing D/E indicates increasing financial solidity of the company.

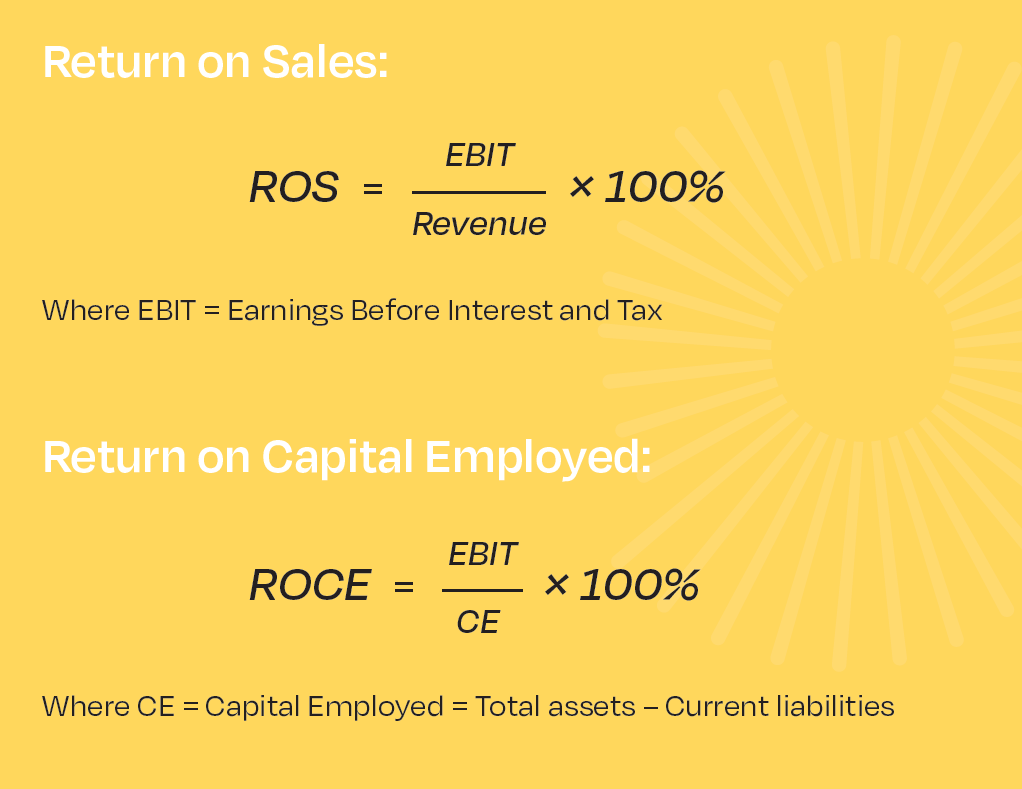

A good indicator of a company’s operating efficiency is reflected by its Return on Sales (ROS, also called EBIT margin):

However, it is to be noted that EBIT may contain tangible book value and depreciation risks. Therefore, EBIT may be a misleading metric where there have been inappropriate depreciation or book value assumptions. Financial return KPIs based on cash flow (like EBIT) positions may reflect a more reliable evaluation base, though the percentage must naturally be higher.

A good KPI for evaluating a company’s profitability is its Net Profit Margin (NPM):

A low NPM means a higher risk of the company running into difficulties quickly if operating cost or competition increases. A larger net margin indicates its higher potential to invest capital into growth (but should be seen in relation to fixed costs).

Apart from the financial stability of the EPC service provider, other means may secure the investor: bank guarantees (e.g., performance bonds), insurance cover solutions, or cash retentions. Bank guarantees, in this example a performance bond, ensure that the EPC service provider is able to pay for liabilities and warranties that might arise from the EPC contract. To receive this type of bank guarantee, the EPC service provider has to pay a percentage to the bank. The downside is that, besides the cost of the performance bond incurred by the EPC service provider, the impact on their available free liquidity. Small EPC service providers, in particular, often face challenges in accessing bank guarantees. In this case cash retentions may secure the investor, i.e., the last payment only occurs after the Final Acceptance Certificate (FAC) is issued.

5.2.2. References and expertise

Experience of the EPC service provider in the construction of PV power plants in a particular country, region, grid environment, for a specific installation type (ground-mounted, rooftop), size and technology can play an important role in the selection procedure. The EPC service provider may provide their references in a track record, to document their experience.

Furthermore, the EPC service provider should document that its staff has the necessary training and certifications to be qualified to build the PV plant. In the case of subcontractors, their experience in the field of activity should also be proven.

Another sign of expertise is the quality approach of the EPC service provider. Apart from potential verifications at the manufacturer’s production site, non-mandatory quality checks during the construction phase are recommended (for more information, see Chapter 7 on Procurement). The extent of checks needs to be adapted to the size of the project.

As part of the expertise, it should be made sure that the EPC service provider has a proper quality management procedure in place.

5.2.3. Price and performance of procurement

Those EPC service providers that are preferred partners of their suppliers get better conditions. This may be a better price, but also better delivery time, secured delivery in case of shortage or favourable warranty conditions and claim solving.

5.3. Handover from project developer to EPC service provider

At the contracting stage, when selecting or appointing an EPC service provider, the developer should hand over all the important documentation about the project and preliminary works (see Annex F, section Basic Design – Development Documentation). This will be the basis for the scope of work negotiation with the EPC service provider and the share of responsibilities between the Asset Owner and the EPC service provider. The main topics to be discussed by both parties include the site description with its particularities, the permitting process and the associated constraints from legal authorities and the technical specifications from the grid connection side.

5.3.1. Site description (including site surveys and site data)

To ensure the best understanding and the most accurate design of the PV plant, a detailed description of the site and all associated constraints should be delivered to the EPC service provider. To pass on responsibilities to the contractor all preliminary studies and surveys should be shared. These documents will allow identifying the requirements and identifying the need for extended study. The main information to be shared is listed in Annex F, section Basic Design. If applicable, some documents from the Pre-Construction Documentation should also be considered.

5.3.2. Permitting process

Developers are typically in charge of obtaining building permits and all authorisations (e.g., from environmental authorities) related to executing works. EPC contracts should mention that service providers need to comply with any relevant permits and authorisations to maintain them. Specific aspects related to the construction period or design of a PV installation can be requested by the relevant authorities and it should be the service provider’s responsibility to provide these during the construction stage:

- Environmental mitigation measures to be implemented (plant trees, restoring grass, exclusion zones for levelling and grading works, measures towards flora and fauna)

- Aesthetic measures for visualisation of the project, landscape integration or sight impact on the neighbouring buildings (electrical cabinet design, height of structures, hedges to be planted)

- Fire and emergency mitigation measures

5.3.3. Grid connection process

The development stage also involves identifying the most suitable point of interconnection with the local network and the best strategy for connecting. This is often discussed at early stages with the network or grid operator, who is normally involved in the technical specification definition, and sometimes (in some countries systematically) in the completion of the works. To ensure timely grid connection and smooth communication between the network operator and the EPC service provider it is important to share the following:

- Grid connection technical specifications, often prepared by the local network operator

- Network operating conditions to be complied with during the operation phase

Additionally, in case of a specific Power Purchase Agreement (PPA), it is recommended that this information is shared with the EPC service provider. If commercial aspects need to be kept confidential then the technical specifications with which the EPC service provider has to comply should be shared, at the very least.