Engineering, Procurement & Construction Best Practice Guidelines (Version 2.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchKey Performance Indicators

There are different types of Key Performance Indicators (KPIs) relevant to EPC, depending on project phase and relevant stakeholders. KPIs related to EPC can be grouped into three categories:

- Ex-ante KPIs allow the (future) Asset Owner (or project developer) to decide whether to invest in a project that is being developed and trust a particular EPC service provider. They also help lenders to assess projects for financing. These aspects are important during the transition from the development to the construction phase and are considered in section 5.1. Selection of EPC projects and section 5.2. Selection of EPC service provider

- Project performance KPIs help all stakeholders to track project progress, and EPC service providers to optimise their processes

- Ex-post KPIs deliver a final assessment on a built project. For EPC service providers these KPIs may also be helpful when presenting their references to potential new clients

The number of criteria to be looked at depends on the value of the project: big projects need to be examined in more detail.

11.1. Project performance KPIs

During the construction phase, the performance of the project should be tracked closely. There are available project management standards for this, such as ISO 21500, or publications of associations like the German Association for Project Management (GPM), or the Project Management Institute (PMI). In principle, project management tracks deadlines, budget, and quality, to achieve planned results.

There exist multiple KPIs for project performance. Here we focus on those which track the three essential elements of the ‘project management triangle’: (1) time, (2) budget, (3) quality. To achieve customer satisfaction, the planned goals concerning these elements have to be respected. The sections below discuss KPIs related to these aspects in more detail.

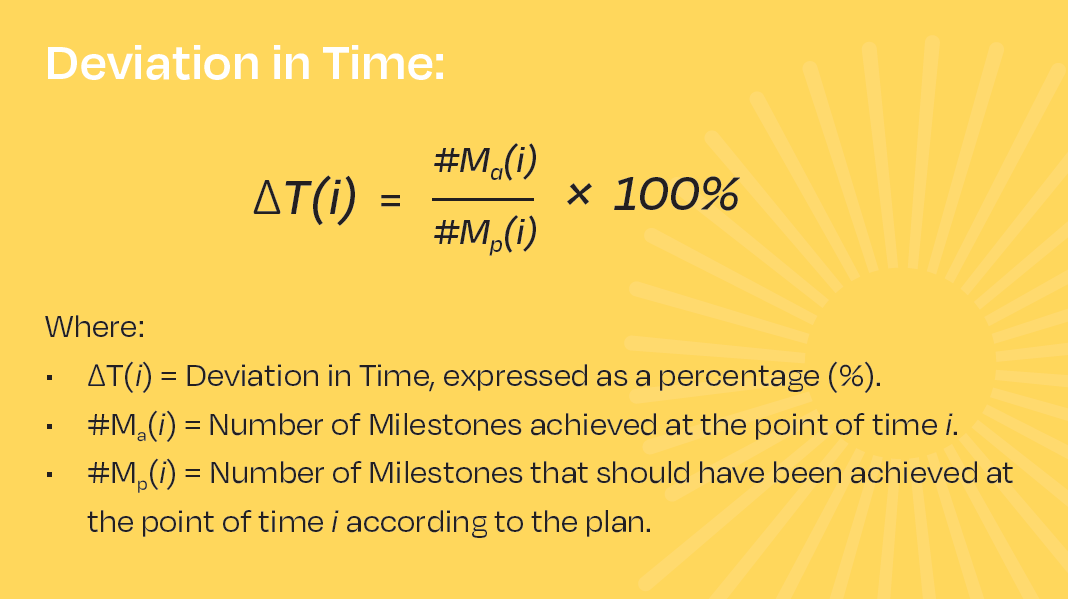

11.1.1. Deviation in Time

Milestones are used in project management to mark specific points along the project timeline. These points may signal anchors such as project start and end date, or the need for external review, input, and budget checks. Therefore, one important KPI concerning time is the Deviation in Time expressed as percentage of milestones missed:

The value of this KPI increases if the granularity of milestones becomes finer and milestones are well distributed over the whole construction phase.

On the contractual side, Liquidated Damages may be linked to Deviation in Time – see section 12.5. Limitation of liability and Liquidated Damages.

Since the importance of different milestones may differ, another KPI should be introduced: the number of Critical Milestones Missed (CMM). A critical milestone is one that must not be missed, because of its significance to the project. Examples include the date of receipt of construction permits or of grid connection. In a normal project CMM should be 0. Additional KPIs may include Deviation of Planned Hours of Work.

11.1.2. Deviation in Budget

At defined moments in the project, usually at milestones and after (or even before) purchase of important components (like modules) or services, current accumulated costs Cca(i) should be compared to costs according to the business plan Cpa(i). The resulting KPI Deviation in Budget can be defined as:

In this case the value of the KPI depends again on the choice of the measurement points i, their granularity and distribution over the period of the project.

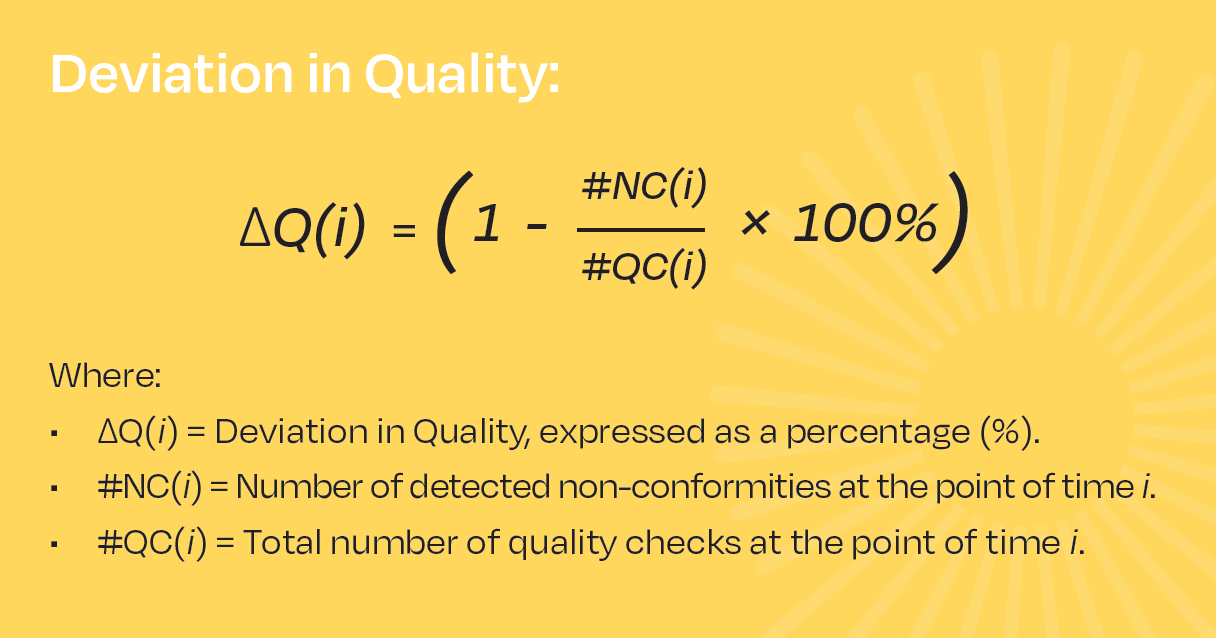

11.1.3. Deviation in Quality

Quality KPIs measure the quality of construction as well as the construction process and are therefore quite technical. A general KPI for quality tracking is the Deviation in Quality, which can be defined as:

The value of this KPI depends on the definition of quality checks, their number, and distribution over the project period. Non-conformities may include:

- Deviations from execution plans

- Construction defects

- Deviations from norms, standards, grid code, and industrial best practice (the documents to be considered should be listed in the tender document)

- Deviations from permits

Tracking certain quality aspects separately, like conformity with HSSE protocols, is recommended. In this case we would count non-conformities in HSSE and only compare it to the number of all HSSE checks.

Since the importance of different quality aspects may differ, it is best practice to assign a weighting factor for each conformity check.

Other aspects of project quality may be examined, for example:

- The number of change requests (indicates the quality of project development and preparation)

- KPIs describing the quality of communication between the stakeholders (surveys)

- The completeness of required documents for the O&M phase (see Annex C of the O&M Best Practice Guidelines)

This list should be completed according to the necessities of the specific project.

It is also important to establish feedback loops to create an atmosphere where continuous improvement can flourish.

11.2. Ex-post KPIs

Ex-post KPIs are the KPIs that help evaluate EPC projects after the construction phase.

11.2.1. Performance Ratio

There are several KPIs that can be used to evaluate overall plant performance, such as PR, and overall Availability of the PV plant.

PR describes the efficiency of the energy conversion system of a PV plant. When calculating PR, one must bear in mind that the efficiency of PV modules also depends on temperature. For a detailed explanation and formulas, please refer to section 10.3.4. Temperature-corrected Performance Ratio of the O&M Best Practice Guidelines.

Availability focuses on the time that a plant spends generating electricity. For a detailed explanation and formulas please refer to Chapter 10. Key Performance Indicators in the O&M Best Practice Guidelines.

11.2.2. Overall project performance

KPIs regarding overall project performance are, in most cases, identical to the Project performance KPIs described in section 11.1., with i being the concluding milestone of the project.

11.2.3. Warranty KPIs

Additional ex-post KPIs after FAC measure the handling of warranty claims by the EPC service provider, for example:

- Number of broken components / Total number of components

- Number of broken components replaced in warranty procedure / Total number of broken components