Engineering, Procurement & Construction Best Practice Guidelines (Version 2.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchIntroduction

1.1. Rationale, aim and scope

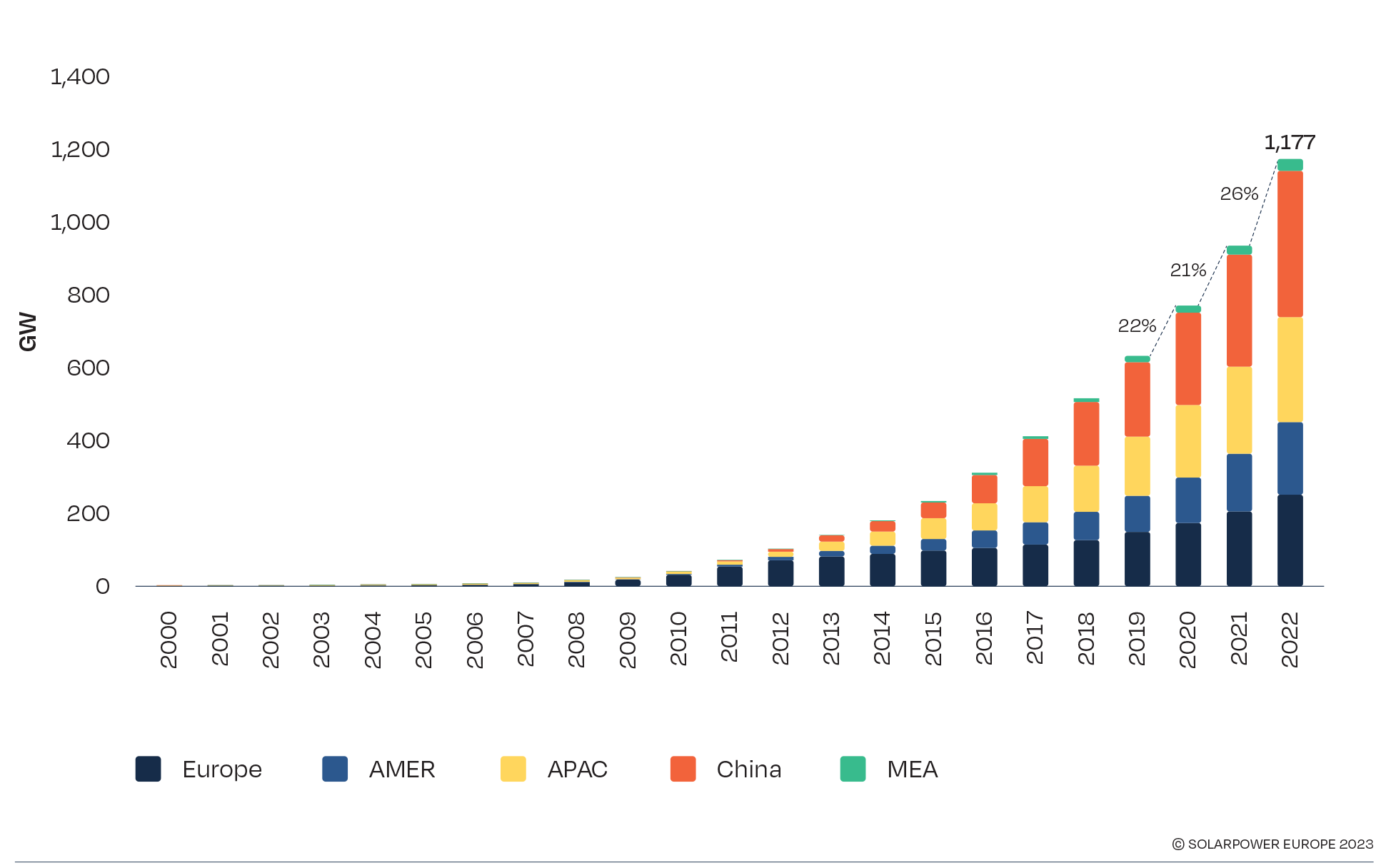

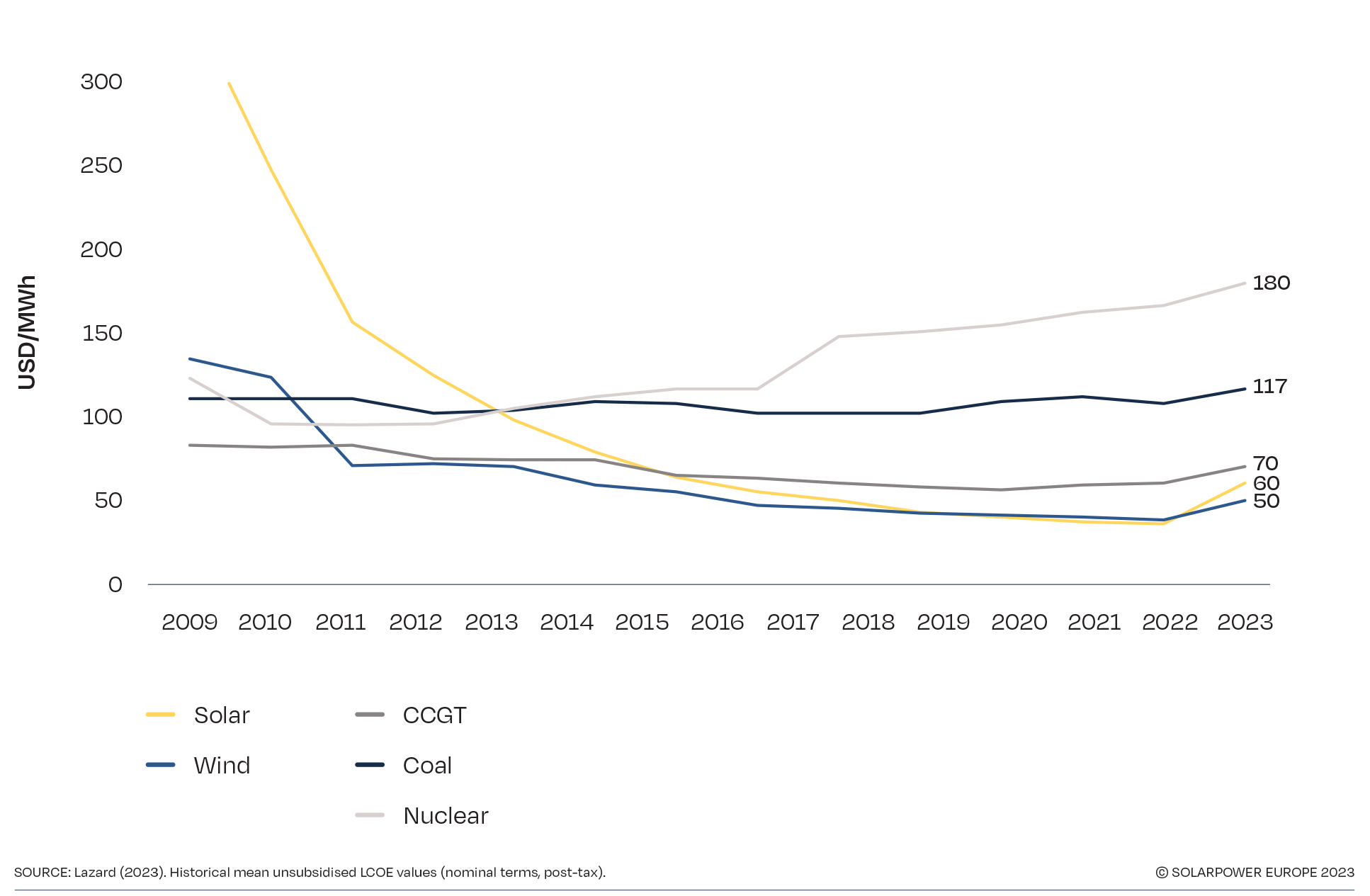

Solar PV is a maturing industry. Its development globally has been phenomenal, with a sustained double-digit annual growth rate in excess of 10% for the last three decades (see Figure 1). This is due to an equally impressive reduction in the cost of the energy produced by the technology (see Figure 2). Sustaining this cost reduction is critical for maintaining competitiveness against other energy technologies. This guide aims to contribute to further cost reductions. The collection of best practices cannot always be understood as a benchmark, as it might not fit to the company and project’s structure.

The cost of PV energy is a function of CAPEX, OPEX, finance, and the amount of energy generated by the PV system. There is relentless competition in the marketplace, which mostly is played out on cost. The four contributions above are often seen as independent of one another and are optimised separately. This may not be ideal. Quality assurance is the link between these elements, as CAPEX savings may lead to higher OPEX or reduced energy generation. One idea behind these Guidelines is to minimise risks linked to this siloed approach to optimisation.

PV assets need to be cost effective to ensure broad acceptance of the technology. Simultaneously, they must deliver against performance expectations to prove their attractiveness to investors. To connect these two, there are different quality assurance strategies that are employed throughout the industry. These Guidelines allow for these different approaches, by detailing what is considered essential to assure a worthwhile asset and indicating optional and recommended additions.

The Guidelines systematically go through the Engineering, Procurement, and Construction (EPC) phases of a solar power plant. It is assumed that quality underpins the entire process, and often the earlier in the process it is introduced, the lower the overall system build, and Operation and Maintenance (O&M) costs will be. For more information on how quality underpins the lifcycle of a solar PV power plant, please refer to section 4.4 Quality Management of SolarPower Europe’s Lifecycle Quality Best Practice Guidelines (available at www.solarbestpractices.com). The links between the “E”, “P” and “C” stages, as well as the links between Development and EPC, and the EPC and O&M phases are described in detail to minimise handover problems. Quality is often assured by the application of standards. There is a comprehensive list of these in Annex A. The Guidelines do not aim to substitute any of these, they aim to support the application of them and point out several relevant uses.

1.2. How to benefit from this document

These Guidelines include the main considerations for a successful and professional EPC service provision. Although they have not been tailored to individual stakeholders, the purpose of the Guidelines is similar for all - understanding the mandatory requirements and the necessity of high quality EPC services, as well as incorporating recommendations into service packages for more effective EPC services. Any of the directly relevant stakeholders (as described above) can benefit from this work, tailor it to their needs without lowering the bar and know what to ask for, offer or expect. The Guidelines are particularly useful for anybody in the industry involved in assessing or minimising risks of an asset. Although the focus is European, most of the content can be used in other regions around the world. The requirements described in the Guidelines apply without changes in other regions and additional requirements or modifications can easily be made for other regions with unique characteristics.

In line with other Best Practice Guidelines of SolarPower Europe the value proposition of this report is its industry-led nature, gathering the knowledge and experience of well-established and leading companies in the field of EPC, AM, O&M service provision, utilities, manufacturers, digital solution providers and insurance providers. The scope of the current second edition includes the utility scale segment and more specifically, systems above 1MW. The Guidelines are based on the experience of companies operating globally (with a focus on Europe) and identify high-level requirements that can be applied worldwide. Specific national considerations such as legal requirements are not included and should therefore be considered separately if the Guidelines are to be used in specific countries.

The content covers technical and non-technical requirements, classifying them, when possible, into the following:

- Minimum requirements, below which the EPC service is considered as poor or insufficient, and which form a minimum quality threshold for a professional and bankable service provider

- Best practices, which are methods considered state of-the-art, producing optimal results by balancing the technical as well as the financial side

- Recommendations, which can add to the quality of the service, but whose implementation depends on the considerations of the Asset Owner, such as the available budget

To differentiate between these three categories, verbs such as “should” indicate minimum requirements, unless specified otherwise, as in, “should, as a best practice” or “as a recommendation”.

1.3. List of abbreviations

AC ... Alternating current

AM ... Asset Management

ASCE ... American Society of Civil Engineers

BESS ... Battery Energy Storge Systems

BOM ... Bill of Materials

BOS ... Balance of System

BRP ... Balance Responsible Party

BTM ... Behind-the-Metre

CAD ... Computer Aided Design

CAPEX ... Capital Expenses

CCTV ... Closed Circuit Television

CFD ... Computational Fluid Dynamics

C&I ... Commercial & Industrial

CMM ... Number of Critical Milestones Missed

COD ... Commercial Operation Date

CPN ... Cost Priority Number

DC ... Direct Current

D/E ... Debt-to-Equity ratio

DEM ... Digital Elevation Models

DoD ... Depth of Discharge

DSM ... Demand-side Management

EBIT ... Earnings Before Interest and Taxes

EIA ... Environmental Impact Assessment

EL ... Electroluminescence

EPC ... Engineering, Procurement, Construction

ERP ... Emergency Response Plan

ESS ... Energy Storage System

EVA ... Ethylene-Vinyl Acetate; Economic Value Added

FAC ... Final Acceptance Certificate

FAT ... Factory Acceptance Test

FMEA ... Failure Modes and Effects Analysis

FTM ... Front-of-the-Metre

GPM ... German association for Project Management

HAZOP ... Hazard & Operability Study

H&S ... Health and Safety

HSSE ... Health, Safety, Security, and Environment

HV ... High Voltage

HVAC ... Heating, Ventilation, Air Conditioning

HVRT ... High Voltage Ride Through

IEC ... International Electrotechnical Commission

IECRE ... IEC system for certification to standards relating to equipment for use in Renewable Energy applications

IFC ... Issue for Construction

IP ... Inverter Protection, Internet Protocol

IRR ... Internal Rate of Return

ISO ... International Organisation for Standardisation

IVPD ... Induced Voltage test with Partial Discharge measurement

KPI ... Key Performance Indicator

kW ... Kilowatt

kWh ... kilowatt-hour

kWp ... kilowatt-peak

LCOE ... Levelised cost of electricity

LD ... Liquidated Damages

LeTID ... Light and elevated Temperature Induced Degradation

LFP ... Lithium Ferro (iron) Phosphate

LID ... Light Induced Degradation

LV ... Low Voltage

MCC ... Mechanical Completion Certificate

MTTR ... Mean Time to Repair

MV ... Medium voltage

MW ... Megawatt

NCU ... Network Control Unit

NMC ... Nickel Manganese Cobalt

NPM ... Net Profit Margin

NTP ... Notice To Proceed

O&M ... Operation and Maintenance

OD ... Operational Document

OPEX ... Operational Expenses

PAC ... Provisional Acceptance Certificate; Pac: AC Power

PCS ... Power Conversion System

PD ... Partial Discharge

PHSSER ... Project Health, Safety, Security, Environment review

PID ... Potential Induced Degradation

PLC ... Programmable Logic Controllers

PMI ... Project Management Institute

POD ... Point of Delivery

POI ... Point of Interconnection

PPA ... Power Purchase Agreement

PPE ... Personal Protective Equipment

PR ... Performance Ratio

PV ... Photovoltaic

QA ... Quality Assurance

QC ... Quality Control

QI ... Quality Improvement

QM ... Quality Management

QP ... Quality Planning

QR ... Quality Review

RACI ... Responsible, Accountable, Consulted, Informed

RFSU ... Ready for Start Up

RFP ... Request for proposal

RFQ ... Request for quotation

RFT ... Request for tender

RPN ... Risk Priority Number

ROCE ... Return On Capital Employed

ROS ... Return On Sales

SCADA ... Supervisory Control and Data Acquisition

SLA ... Service-Level agreement

SLD ... Single-Line Diagram

SOC ... State of Charge

SPV ... Special Purpose Vehicle

SSSP ... Site-Specific Safety Plan

STC ... Standard Test Conditions (1000 W/m2, 25°C)

STEM ... Science, technology, engineering, and mathematics

TA/SWMS ... Task Analysis/Safe Work Method Statement

TCU ... Tracker Control Unit

TSO ... Transmission System Operator

UPS ... Uninterruptible Power Supply

UV ... Ultraviolet

VPP ... Virtual Power plant

WBS ... Work Breakdown Structure