Asset Management Best Practice Guidelines (Version 2.0)

Do you prefer the guidelines as a pdf file?

Download PDFAre you interested in downloading a specific chapter?

Search the reports?

SearchData management and high-level monitoring

Asset Managers have the responsibility of monitoring and overseeing the activities performed by the O&M service providers as well as managing the ongoing obligations of the plant to ensure its longevity and profitability, as detailed in the previous chapters.

All different positions borne by the Asset Manager can benefit from new digital instruments, which allow for more efficient data management and ensure the best, most cost-effective power plant operation. These instruments include plant performance advanced data analysis and management, O&M site activity supervision, contract management, administrative follow-up and optimisation. Ideally, an Asset Manager should make use of an Asset Management Platform that can undertake all of the digital aspects or can link to external specific digital tools to consolidate all relevant information. There is tendency in a maturing industry to opt for solutions that integrate the functionalities of Monitoring Systems, Computerised Maintenance Management Systems (CMMS), Digital Twins and Enterprise Resource Planning Systems (ERP) in one software. Such integrated solutions allow Asset Managers (and O&M Contractors) to analyse all parameters including plant technical data, maintenance activities related information (including all costs associated to it) and contractual data in one central platform. Such integrated solutions can be considered a recommendation.

Advanced data analysis services come in many forms, with the most sophisticated using special algorithms including machine learning for exploring big data to surface value and enable predictive analytics. Service providers with experience and knowledge in the solar industry can combine this with digital analytics to transform data into intelligence and thus develop decision support systems. Hidden problematic areas in a solar asset can be identified and concrete actions for performance maximisation provided. In addition, strategies for reducing O&M costs, based on comprehensive plant data, can be devised. Another aspect which is increasingly being offered to make operations more efficient is the automation of monitoring, also possible in combination with, and as a side benefit of, advanced data analysis. The latter also simplifies the overall reporting documentation side for Asset Managers. Many suppliers offer web-based dashboards to simplify integration and allow for Results-as-a-Service. There is also a further trend towards the use of autonomous platforms providing advanced data analysis to allowing the Asset Manager to integrate this as a product as opposed to a consulting service. The remote nature of the service also means that it can be integrated into a Monitoring System & Asset Management Platform and no hardware or software installations are necessary.

Additionally, the Asset Managers must have access to all data that the O&M service providers have at their disposal and the technical and operational data generated from the O&M service providers’ activities. Asset Managers are further responsible for capturing all data related to their various activities, such as cost and financial data, commercial data, compliance data, contractual & regulatory data as well third-party data, necessary for the Asset Owners. Asset Managers are required to provide regular status reports to Asset Owners and require access to data provided by the O&M service provider relating to the monitoring of the plant, O&M service repair activities, and all data related to necessary compliance processes.

A reliable and fast internet connection is key to enable the above. 5G is the next wireless standard for Internet connectivity. It is presented as an opportunity to enable the energy transition by facilitating the management of distributed, variable and unpredictable energy generation such as solar PV. The reason for this lies in 5G properties, amongst which increased data flow capacity and lower latency of signals are key for an efficient distributed energy generation. The increased data flow capacity will enable the communication from, to and between the large number of devices and sensors that are needed to master the operations of smart grids in a robust and reliable way, especially with respect to self-consumption and storage technologies management. This is relevant for example to determine the best cycling of batteries for their life improvement or to ensure that critical load appliances power supply is always made available with the highest priority. In an effort to avoid congestion to the grids that might be caused by unpredictable renewable energy generators, the low-latency capability of 5G is crucial. It is said to be in the order of 20ms for remote sites, which can be considered a nearly real-time signal capability. This is also made available by dedicating some bandwidth, the so-called “network slicing” to specific crucial activities such as commanding power plants to turn off or derating their power generations within the shortest, near-real-time delay.

Asset Managers should comply with the following guidelines regarding data and data management to ensure the most efficient operation of their power plants. To be able to achieve this, the Asset Managers should use an Asset Management Platform.

10.1. Asset Management platform functionalities

An Asset Management Platform is a software package or suite of tools that is used by the Asset Manager to store and manage technical and non-technical data and information collected from and relating to the solar asset, portfolio or SPV. It combines the abilities of a Computerised Maintenance Management System (CMMS) and an Enterprise Resource Planning System (ERP) into an Enterprise Service Management System

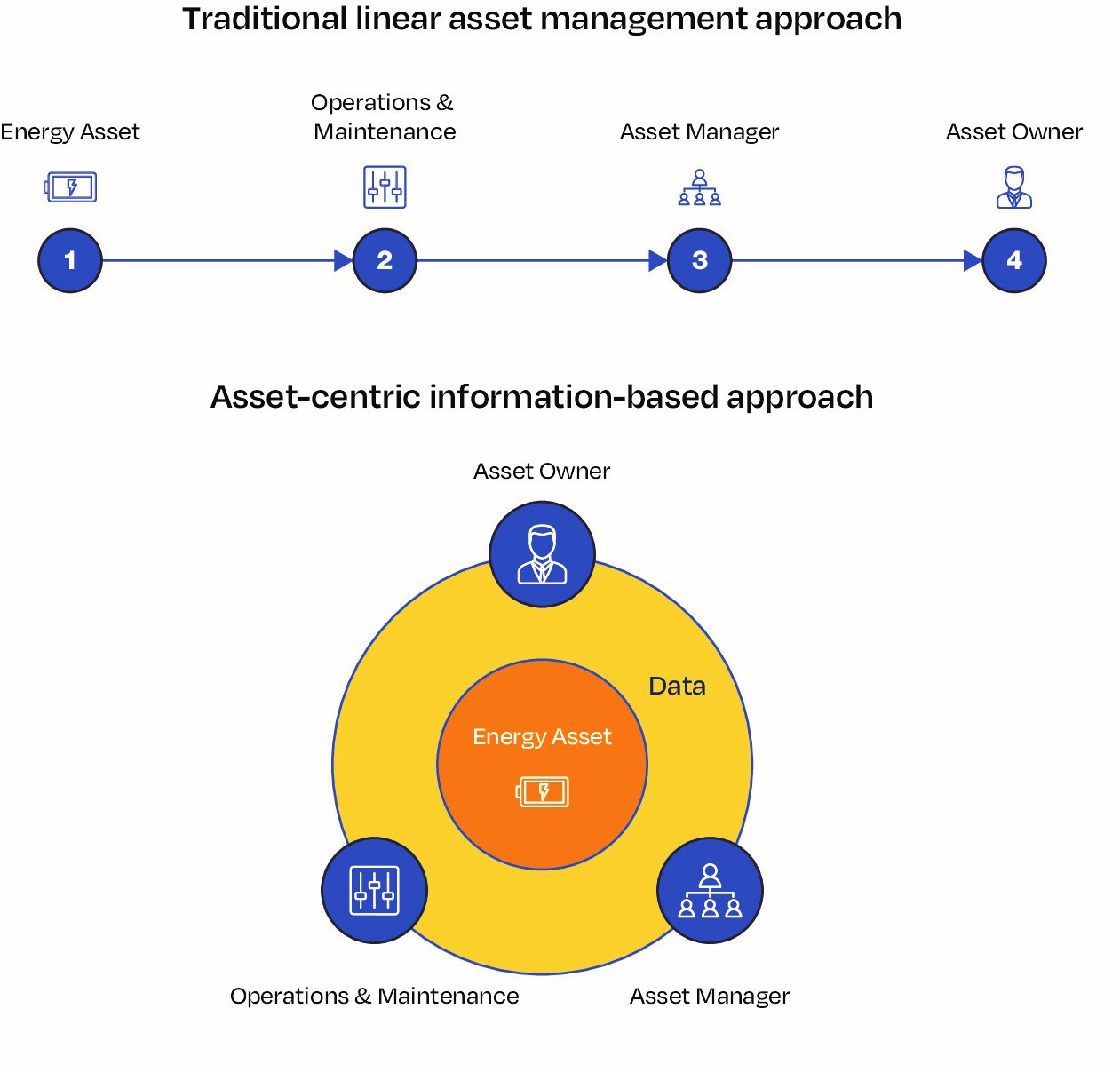

It is the Asset Management Platform that makes it possible for the solar industry to transition to an asset-centric, information-based management approach, which addresses three key challenges: (1) loss of generation and income, (2) loss of time, and (3) lack of transparency. This is in contrast to the traditional linear Asset Management approach, where information flows from the asset through the O&M Contractor to the Asset Manager and ultimately to the Asset Owner. This linear approach means that the Asset Owner does not have direct access to data from the solar power plant and, rather, information is filtered before reaching the asset owner, creating a lack of transparency and mistrust between the three key stakeholders.

This section presents how Asset Management Platforms support the Asset Managers in their roles and responsibilities.

10.1.1. Reporting

The Asset Manager should collect and share with their clients all key data/deadlines to demonstrate compliance with the expected deliverables set out in the Asset Management contracts. In some cases, based on a client’s requests and SLA, delays or failures associated with the fulfilment of such obligations may result in the Asset Management company having to pay penalties (consider referring to the chapter on contractual framework).

The key data/deadlines should be identified based on the client’s priorities and agreed scope of work. However, some typical areas are identified and summarised in the table below:

| DESCRIPTION | FREQUENCY |

| Date of delivery of AM reports | Based on client requirements (typically monthly) |

| Date of delivery of annual budget | Annually |

| Technical KPIs verified | Monthly |

| Revenue data | Monthly |

| Cash balance and reforecast | Monthly |

| Key contractual deadlines | Quarterly |

| Plant incidents (open, pending and closed) | Monthly |

| Financial reports (Balance Sheet, P&L, CASH FLOW), also on a consolidated basis | Quarterly |

| Reports for state or local agencies and authorities | Annually or as per country requirement |

TABLE 17 - FREQUENCY OF KEY DATA PROVISION

Once identified, these requirements and activities must be calendarised in the Asset Management Platform. Apart from simple calendar entries, the platform should also include escalation features, for example for overdue items, to ensure that important tasks are not neglected. Such escalation should ideally involve multiple team members, depending on their role and position in the hierarchy.

10.1.2. Site construction due diligence

The Asset Manager should perform due diligence on the knowledge and expertise of the EPC contractor. All documentation and certification should be digitalised in the Asset Management Platform’s Documentation Management System (DMS). Re-certifications and training schedules should be calendarised. It is essential that the Asset Manager sources impartial and independent testing, inspection and oversite during the key milestone reviews.

10.1.3. Optimisation of energy production

Power plant KPIs and O&M Contractor KPIs, as defined in chapter 10. Key Performance Indicators of the O&M Best Practice Guidelines, should be calculated automatically by the monitoring platforms and should be integrated in the Asset Management Platform and used as a reference for contract compliance. It is important that these KPI calculations take various contractual clauses (exclusions) into consideration, for example in periods of force majeure events.

10.1.4. Regular updates and software reliability

Asset managers should be involved and interested in further developing the capabilities of the Asset Management Platform they utilise. This can be done through typical feedback mechanisms with the chosen software vendors utilised, but this can also mean using broader parts of the Platform to further digitalise operations as the Asset Manager evolves with functionalities.

The implementation of an Asset Management Platform can often serve as a great opportunity to continuously review internal activities and processes to ensure that Asset Managers are focusing on value added activities rather than data entry.

The Asset Management Platform must be updated continuously and during every update performed, it must be able to continue collecting the technical data from the monitoring systems within which it is integrated.

Asset Managers should also take steps to ensure the reliability and bankability of their software vendors as this may impact data continuity in their operations. See section 10.7. Data Portability, Backup and Disaster Recovery below.

10.1.5. Lifecycle data collection

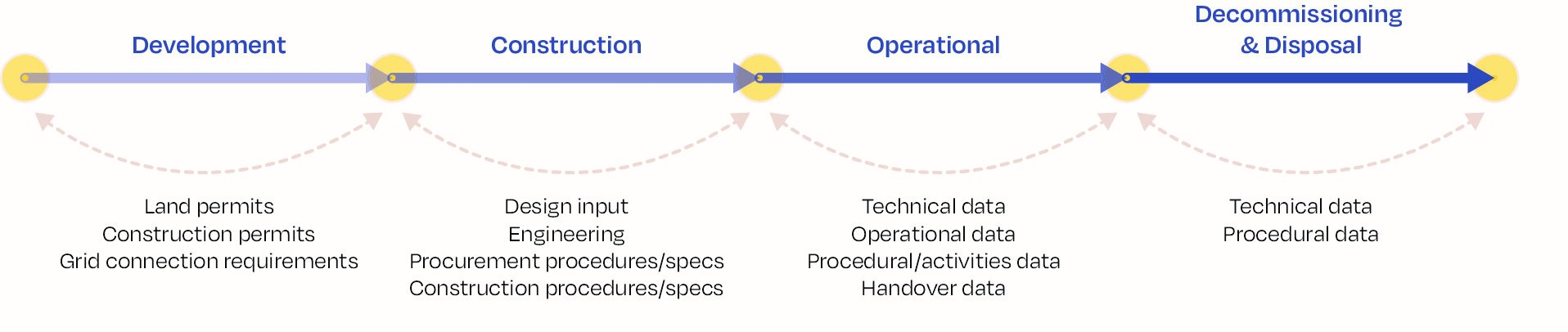

To ensure investment durability, it is recommended that the Asset Manager is involved in the project from the development and construction phases, collecting and managing all related data at each phase for easy and comprehensive reporting. This task can be streamlined through collaborations, incorporating advanced digital twins and data analysis into the traditional AM structure – something that is increasing in popularity. Moreover, the AM should, as a best practice, utilise data and lessons learnt across project portfolios.

10.1.6. Operational risk management

The Asset Management Platform should collect and monitor relevant data in order to mitigate the major risks which may arise during the life of the assets, in particular:

- Keep track of serial numbers of components replaced to ensure the required communications to relevant authorities have been submitted (to avoid risks related to the authorisations in place)

- Monitor and record all relevant maintenance interventions, including cost data, conducted in order to ensure that the plants are kept in an efficient status. It is becoming more common for Asset Managers to commission annual aerial thermographic inspections to better understand the overall health of an asset.

- Ensure key terms of insurance policies (e.g. deductibles, maximum reimbursable amounts) are consistent with the existing level of risks

- Calculate and monitor relevant covenants (D/E, DSCR, LCCR) related to the financing in place (if any).

10.1.7. Procurement process management

The Asset Management Platform should enable the activities explained in chapter 8. Procurement by collecting relevant data to properly manage the procurement process in relation to key suppliers (i.e. number of plants with similar features to benefit from scale effects, contractual deadlines, warranty termination dates).

10.1.8. Deadlines management

In order to be fully compliant with regulatory requirements, an Asset Management Platform should support the Asset Manager in tracking and keeping under control the relevant deadlines for the required communications and collect the information that needs to be provided (e.g. annual production data requested by municipalities).

10.1.9. Health & Safety records

The Asset Manager must ensure that adequate records are kept in the Asset Management Platform to ensure and demonstrate that relevant H&S standards and requirement are set and maintained. It is expected that a set of metrics will be agreed between parties to allow the reporting of events on site and encourage and judge adherence to standards and incremental improvements to the systems and associated standards.

10.1.10. Incidents records

To manage incidents and dysfunctions, the Asset Manager needs to record and have access to all data related to the solar asset, portfolio or SPV. Such data includes technical, operational, financial and market data.

10.2. Types of data collected through the Asset Management Platform

To ensure a full picture of the performance of a project, Asset Managers rely on several sources of data or information. Typical data sources include:

- Monitoring service providers

- Inverter data providers

- Data acquisition solutions

- Meter operators

- Aerial inspection data providers

- Satellite data providers

- Weather forecast data providers

- Energy exchanges

- CMMS solutions

- Exchange rate data providers

- Accounting solutions and ERP systems

For each source, it is important what data the Asset Managers are collecting, at what frequency and when. Beyond this, it is also important to understand the necessity and relevance of collecting and aggregating such data. Data is analysed and collected to enable good decision-making. To do so consistently requires good quality and reliable data. Data reliability can be enhanced through a data cleansing and data quality checking process via external data analysis services, should this not be possible or covered in the O&M scope.

It is important that the Asset Management Platform can generate consolidated reports with much of the data listed below. There are reports, for example technical reports, that are needed on Plant level, but some high-level reports, like financial statements, are needed both on Plant as well as Portfolio level. Here are some key types of data that an Asset Management Platform should have access to:

10.2.1. Technical data

Refers mostly to PV power plant data as referenced in chapter 10. Key Performance Indicators of the O&M Best Practice Guidelines:

- Raw data measurements: data obtained directly from the PV plant and used for performance calculation.

- PV power plant KPIs using the raw data from the PV plant to give a more balanced overview of the operation of the PV plant.

10.2.2. Operational data

Operational data goes beyond the technical data to encompass other relevant interpretations of the technical data as well as activities performed or logged by the O&M contractor:

- Alerts driven or identified by the monitoring systems.

- Decisions made by Technical Asset Managers based on alerts or technical data, including the overall timeliness of such a decision or response.

- “On- or Off-site” actions taken by the O&M contractor, including (a) he overall timeliness of such decision or response (see 11.2. O&M Contractor KPIs of the O&M Best Practice Guidelines); (b) Warranty & Insurance information (if needed); (c) spare parts used.

- Updated forecasts or performance projections. Its important that the Asset Manager understands and has confidence in the asset Yield and PR calculations.

- Records of maintenance, repairs and updates to the system.

- Compliance with technical permits or agreements (interconnection, water, environmental).

10.2.3. Financial and commercial data

Also, financial and commercial data should be integrated into the Asset Management Platform and be linked to technical and operational data when possible (e.g. costs of a specific maintenance intervention, cost of an insurance claim) and seen holistically should include, at the very least, budgeted and actual figures on:

- Revenue (including any incentive programs)

- Billings, payments & collections

- Expenses (including financing costs, with a focus on planned vs. unplanned expenses)

- Financing information and expectations (debt, equity, etc.)

- Financial statements (balance sheet, profit & loss, and cash flow statements)

- SPV administration (signatories, authorisations, structures, requirements)

- Tax status, filing timings, etc.

- Insurance (status, conditions, claims, etc.)

- Documentation (requirements, key documents, etc.)

- Compliance records

10.2.4. Contractual and regulatory data

Solar projects are usually constrained by several agreements and regulations. Asset Managers need to have all relevant information at their fingertips to be effective and efficient, as they are often responsible for the contractual administration and regulatory compliance of their projects.

Data related to contract management:

- Amendments

- Updates

- Renewals

This goes beyond simple contract administration and management to include:

- Legal compliance

- PPA administration with all that they entail (calculations, frequency, escalators, terms & conditions, etc.)

- Power Generation License

- Building & environmental permits

- Stakeholder engagement requirements

- And any other contractual requirements

10.2.5. Third-party data

Asset Managers not only need to understand and aggregate data that come from their projects and their operations, but also, more and more Asset Managers need to understand how to deal with and manage data and information coming from third parties.

Market data

With more and more solar projects starting to have exposure to market conditions and trading opportunities, electricity market information is becoming increasingly important. This can include nodal prices, spot prices, future prices, price forecasts, etc. Ultimately, the structure of the agreement surrounding the market dispositions of a project will clearly dictate what to monitor, log and watch. This can be grid measurements, rates, schedules, etc.

Weather data

This is often lumped in with technical data through an on-site pyranometer or weather station, but more and more third parties offer reliable data feeds that can be incorporated into an Asset Manager’s overview or simply as a validation point for on-site equipment.

Other data

Additional types of data sources can be accessed. The important point is to understand why these sources matter and the business objective behind them.

10.3. Data format

The data format of the recorded data files must respect standards such as IEC 61724 and must be clearly documented. Data loggers should collect all inverter alarms in accordance with the original manufacturer’s format, to ensure all available information is obtained.

To improve data quality, standardisation of data sources would help avoiding any need for manual data processing of normalisation and reformatting before any aggregation. In this way, data exchange – before or after aggregation – between stakeholders will happen with increased transparency and reduced time.

This is especially important for PV plant metadata (e.g. location, number of components, nominal power, electrical drawings, position of components in the field, etc) which is of fundamental importance for the creation of a PV digital twin and for the calculation of metrics needed in decision support systems.

A best practice is that all data are stored in the same database before any processing.

10.4. Aggregating data

Data collected from the site shall follow a rigorous normalisation and aggregation process where the most accurate site data model is taken into account. The data model shall be shared between AM and O&M in such a way that the same rules of data processing are applied. As an example, a thorough data cleaning, the process of recognizing and interpreting wrong signals, is the basis for a correct data aggregation in the small scale before aggregating at larger time and object levels. Using the same photovoltaic model including loss computations and performance formula will result in an increased transparency and an easier communication between parties and an in general will allow smoother and cost-effective reporting and communication processes.

Often the information gleaned from any data source is of relevance at the individual asset level; however, it can increase in value across multiple projects. At an aggregate level, looking at trends or precursors, we can see the compounding effect of variances and quantify/identify systematic risks that would not be as visible on a single project. A definitive best practice is the ability to view and interact with different types of data at the portfolio and asset level. Third-party data analysis providers are being increasingly integrated into the traditional Asset Manager/O&M structure for exactly this purpose in the case of larger portfolios with disparate O&M providers.

Often enough different data types will have different taxonomies, definitions and formats. And in a similar fashion they may “live” in different systems. Thereby the best practice of aggregating this information is in a primary Asset Management system.

10.5. Interoperability

A central asset management platform should gather together all information available from several digital tools and hardware and provide a centralized working interface accessible to any stakeholder internal and external to the asset management company. The asset manager shall be able to attribute to any user an access with restricted data and functionality visibility depending on the degree of confidentiality and the function of the stakeholder.

This way, the same set of data can be easily accessed from different angles allowing the best efficiency, quality and transparency of information exchange.

A versatile asset management platform shall be able to embrace information coming from any existing and future digital service by supporting all protocols listed in the table below and having a flexible model that could easily interpret a new set of parameters and KPI that could appear to be relevant for the business.

As a best practice, the system should ensure open data accessibility, to enable an easy transition to Asset Management Platforms. The table below shows some examples of data integration options. Due to the lack of unifying standards, this is normally not the case and every Monitoring System provider has their own method to store and retrieve data. Best practice systems have the possibility to retrieve data by using open APIs such as RESTfull, providing interoperability between different systems.

| METHOD | ADVANTAGES | DISADVANTAGES |

| FTP Push or FTP Pull | Easy to implement No need for additional hardware | Not secure unless: - proper VPN is set up, - using sFTP or FTPs encryption method, - FTP access control methods implemented. Limited control of data flow to the FTP server |

| Modbus/TCP (with additional logger on site) | Reliable and secure Best control of data flow | Additional cost for additional hardware More time-consuming implementation Relies on the existing monitoring system hardware, hence, two hardware vendors involved |

| API (or similar) in the cloud | Fast and easy to implement No need for additional hardware Reliable depending on providers’ conditions and communication conditions | Small time lag from data collection to final destination (data pull technology requires automated back-filling technology in case of data gaps or communications issues). Relies on the existing monitoring system vendor, double fees for monitoring. (No control over data) API may face data quality issues and limits – data granularity, data depth, availability, correctness, currentness, completeness – depending on the provider’s terms conditions (SLAs) and technical abilities. |

TABLE 18 - EXAMPLES OF INTEGRATION OPTIONS

10.6. Cybersecurity

In order to enhance cybersecurity, the Asset Manager typically performs also periodic audits on the main suppliers (the O&M contractors in particular) who have access to relevant data and connectivity of the plants. The audit mainly aimed at ensuring that the personnel is properly trained in relation to procedures for data protection (e.g. policies related to passwords, protection of access to relevant devices) and can detect and avoid possible cyber-attacks.

In addition (as clarified in chapter 8. Procurement), as part of the risk mitigation activity, the asset managers support plant owners in identifying and activating insurance policies that also cover the risks of indirect damages (i.e. missed productions) deriving from cyber-attacks. Since such attacks, in some extreme circumstances, can even determine plant outages that may require a long period of time before being solved, an insurance coverage is particularly relevant to avoid the exposure to significant revenues losses.

Ultimately the role of the Asset Manager is often to raise awareness about the importance of cybersecurity as it relates to the management of the plants.

Since PV plants will at least include inverters and power plant controllers (and monitoring systems) and these are expected to be accessible from (i.e. connected to) the internet to enable surveillance and remote instructions by operators, they have significant exposure to cybersecurity risks.

Cybersecurity comprises technologies, processes and controls that are designed to protect systems, networks and data from cyber-attacks. Effective cyber security reduces the risk of cyber-attacks and protects organisations and individuals from the unauthorised exploitation of systems, networks and technologies.1

Cybersecurity is a vast area and multiple measures are imaginable. The following hints may help as a starting point:

→ Keep it simple: If possible, the number of network devices should be reduced to a minimum.

→ As a recommendation, traffic of the network devices may be monitored in order to detect abnormally high use of bandwidth.

→ Physical access to the network devices should be secured and a secure password policy should be implemented. The use of standard passwords should be especially avoided, and all factory setting passwords should be changed.

→ Access from the Internet should be controlled via strict firewall rules:

- Port forwarding should not be used because this is a big security gap. Only router ports that are necessary should be opened.

- Remote access should be limited to the necessary use cases.

- The use of VPNs (Virtual Private Networks – a secure connection built up from the inside of the private network) is necessary.

- VPN access to the site from outside is a minimum requirement.

- A VPN server or VPN service which works without requiring a public IP on-site should be preferred.

- Each PV plant should have different passwords.

- Documentation should be kept up to date to be sure that no device was forgotten.

- Different roles should be used to the extent possible (e.g. read only user, administration access).

- Professional (industrial grade) hardware should be used; only such hardware provides the security and administration functions plants need to be secure.

→ Vulnerability management should be implemented (i.e. identifying and remediating or mitigating vulnerabilities, especially in software and firmware) by:

- Improving insecure software configurations.

- Keeping the firmware and software of devices up to date.

- Using anti-virus software if possible and keeping it up to date.

- Avoiding wireless access if it is not necessary.

- Auditing the network with the help of external experts (penetration tests).

→ Keeping companies safe:

- Passwords should not be stored in plain text format, password managers should be used (e.g. 1Password, Keepass etc).

- Employees should be trained on IT security awareness.

- Not all employees should have access to all plants. Only those should have access who need it. This way damage can be prevented in case one employee is hacked.

- Management of leaving and moving employees: in case a plant overseeing employees changes positions or leaves the company, the respective plants’ passwords should be changed.

It is therefore best practice that installations undertake a cyber security analysis, starting from a risk assessment (including analysis at the level of the system architecture) and implement a cybersecurity management system (CSMS) that incorporates a plan-do-check-act cycle. The CSMS should start from a cybersecurity policy, and definition of formal cybersecurity roles and responsibilities, and proceed to map this onto the system architecture in terms of detailed countermeasures applied at identified points (e.g. via analysis of the system in terms of zones and conduits). These detailed countermeasures will include the use of technical countermeasures such as firewalls, encrypted interfaces, authorisation and access controls, and audit/detection tools. But they will also include physical and procedural controls, for example, to restrict access to system components and to maintain awareness of new vulnerabilities affecting the system components.

As minimum requirements, loggers should not be accessible directly from the internet or should at least be protected via a firewall. Secure and restrictive connection to the data server is also important.

The manufacturer of the datalogger and the monitoring platform should provide information on penetration tests for their servers, any command protocol activation channels and security audits for their products. Command functions should be sent using a secure VPN connection to the control device (best practice). Double authentication would be an even more secure option.

For further information, beyond the scope of this document, please look at the EU Cybersecurity Act (EC, 2019) and the European Parliament’s study “Cyber Security Strategy for the Energy Sector” (EP, 2016).

1 Definition: https://www.itgovernance.co.uk/what-is-cybersecurity.

10.7. Data portability backup and recovery

The data from the Asset Management Platform, or component systems, should always be legally owned by, and be accessible to, the Asset Owner (SPV). Stakeholders such as the O&M Contractor, the Asset Manager or auditors, during due diligence phases, that need the data to perform their duties should be able to be granted access.

Depending on whether you rely on an in-house built platform or rely on external vendors, these specific considerations should be key requirements that are passed on and included as part of the scope of the Asset Management Platform.

Consideration should be given to how the data contained within the Monitoring Systems, Asset Management Platform, and that is generally collected by the Asset Manager, is protected to ensure the long-term availability in the case of change of provider either through:

- Managed change of Asset Manager, O&M provider or Monitoring System/Asset Management Platform

- Unexpected change of Asset Manager, O&M provider or Platform (e.g. insolvency)

- Transfer of ownership of the SPV.

Key to the above is a full understanding of the data being collected at all levels and having agreements in place to make it accessible and ensure it is continuously backed up.

An important consideration in these matters is to understand what underlying system is the “system of record” for any given type of information as it will inform the backup strategy required for each initial “source” of data. It is recommended that the Asset Management Platform should keep a copy and log of all data saved if other systems feeding information into the Platform encounter problems.

| CATEGORY | MINIMUM STANDARD | BEST PRACTICE |

| Technical data | Plant production monitoring with data collected at least once every 24 hours | Plant monitoring data collected in 15-minute intervals |

| Financial & commercial data | Yearly presentation of balance sheet, profit & loss, and cash flow statements | Monthly presentation of balance sheet, profit & loss, and cash flow statements |

| Contractual data | Yearly extension/renewal of contractual data and reporting | Yearly extension/renewal of contractual data and monthly reporting on all contractual related activities (i.e. O&M service provider’s activities) |

| Legal data | Yearly extension/renewal of legal responsibilities | Monthly reporting on legal responsibilities |

TABLE 19 - DATA BACKUP MINIMUM REQUIREMENTS

The Asset Manager should endeavour to make sure that all data contained within the Asset Management Platform is correct and up to date, to the extent possible. The Asset Manager’s ability to properly maintain the Platform should be evaluated regularly. It is expected that the Asset Manager’s staff and any other users of the Platform should be appropriately trained in how to use it.

As a best practice, software vendors should be able to offer a variety of failsafe and backup options to Asset Managers. They should have as per the Information Systems Audit and Control Association (ISACA):

- Developed a comprehensive backup plan – How and at what frequency are backups done and what are the possibilities for rollback and data recovery?

- Perform effective backup management – Are they hosting their own servers or relying on cloud service providers?

- Perform periodic databases restore testing – Have they performed restores of their backups?

- Have backup and recovery Service Level Agreements (SLAs) drafted and communicated to all stakeholders – What are the severity levels, what are the guarantees, what are their remedies? What business interruption clauses exist?

- Have the disaster recovery plan (DRP) database portion drafted and documented. Has this all been documented by the vendor?

Asset Managers, as customers of these software companies, can further increase their security by asking for:

- Specific SLAs that refer to their own backup strategy

- Dedicated instances of the application

- Code Escrow agreements to secure against bankruptcy.

Ultimately, data portability, security and recovery are everyone’s prerogatives and should be discussed with all technology providers.

They should also test the ease of data export/API connectors of their software vendors for more commercial reasons.

10.8. Handover of data and documents

For detailed information on the handover of data and documents, please refer to chapter 5. Handover of solar assets.